Loading ...

Loading ...

Loading ...

FRAME AND TOW HOOKS

Your vehicles chassis is manufactured with frame rails of either HSLA

steel or heat-treated steel. Each must be handled in a specific manner to

ensure maximum service life. Before attempting frame repair or

modification, consult the service manual or your dealer.

It is important, particularly on vehicles where the tow hooks are used

frequently to inspect the front and rear tow hooks for damage or a loose

mounting.

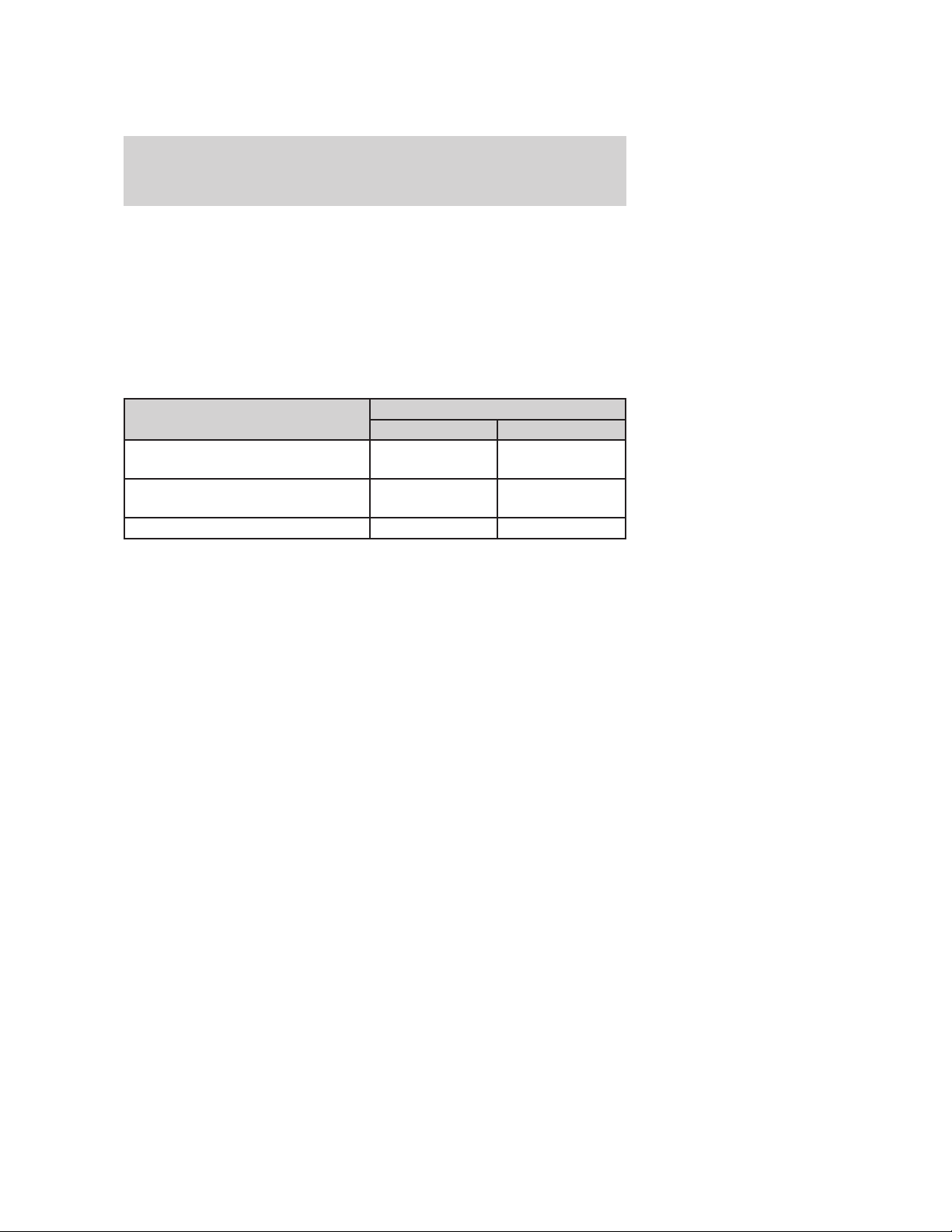

U-BOLT NUT TORQUE

U-bolt diameter (nominal) (all

spring suspensions)

U-bolt diameter (nominal)

Ft. lb. N•m

IROS Air w/15,500 lb. axles and

less

260–300 353–407

IROS Air w/greater than 15,500 lb.

axles

370–400 502–542

Hendrickson 23,000 lb. axle 370–400 502–542

Air suspension U-bolt checks and re-torquing procedures

1. Inspect the threads of the U-bolt and nut for rust and debris. Clean

the threads if contaminated.

2. Using a torque wrench, determine if any nuts can be turned with a

force below the specified torque.

3. Using the lowest discovered torqued nut as a starting point, retighten

the nuts using the sequence listed under Air suspension U-bolt and

U-bolt nut installation.

Air suspension U-bolt and U-bolt nut installation

1. Inspect the threads of the U-bolt and nut for rust and debris. Clean

the threads if contaminated.

2. Install the U-bolts and nuts and torque the nuts to 15 ft. lb. (20 N•m),

using a diagonal pattern.

3. Re-torque the nuts to 100 ft. lb. (136 N•m), using a diagonal pattern.

4. Re-torque the nuts to 200 ft. lb. (271 N•m), using a diagonal pattern.

5. Re-torque the nuts to 400 ft. lb. (542 N•m), using a diagonal pattern.

(For vehicles equipped with 14ACC, 14 ADN and 14ADP axles, do not

use Step 6.)

2006 F-650/750 (f67)

Supplement

USA (fus)

Maintenance and Specifications

206

Loading ...

Loading ...

Loading ...