Documents: Go to download!

User Manual

- Owner's manual - (English, French, Spanish)

- Operating instructions.

- Consumer Help Indicator

- Care and cleaning of the washer.

- Installation Instructions

- Before you call for service…Troubleshooting Tips

Table of contents

User Manual Electric Washer

Operating instructions.

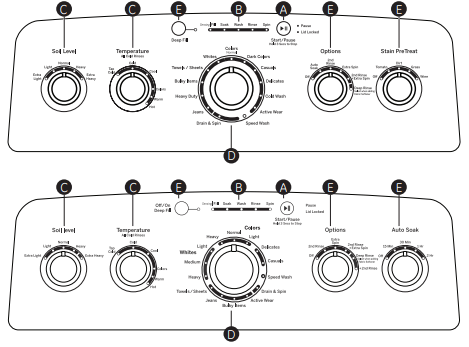

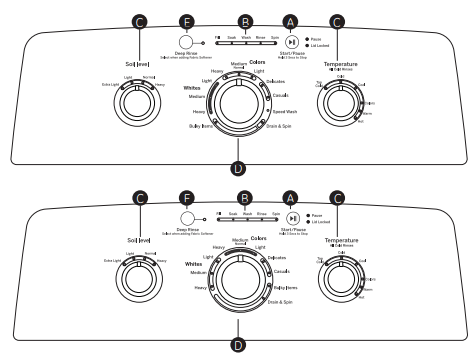

Controls

Start/Pause

Start/Pause

Press Start to begin the cycle. NOTE: The lid must be closed for the washer to start the cycle. If the lid is closed, the lid will lock and the Lid Locked light will illuminate.

Pressing Pause will unlock the lid (if locked at that time), pause the cycle and the Pause indicator light will blink.

To continue the cycle, press Start again. If machine is paused more than 24 hours, the cycle will be canceled. If water remains in the machine, select the Drain & Spin cycle to drain basket and spin water out of the washer basket.

Cycle Status Lights

Cycle Status Lights

Shows whether the washer is in the Fill, Soak, Wash, Rinse or Spin portion of the cycle.

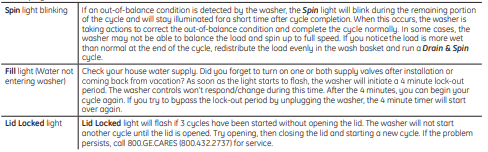

If an out-of-balance condition is detected by the washer, the Spin light will blink during the remaining portion of the cycle and will stay illuminated for a short time after cycle completion. When this occurs, the washer is taking action to correct the out-of-balance condition and complete the cycle normally. In some cases, the washer may not be able to balance the load and spin up to full speed. If you notice the load is more wet than normal at the end of the cycle, redistribute the load evenly in the wash basket and run a Drain & Spin cycle.

Settings

Settings

Select settings for agitation (Soil) and water temperature (Temp).

NOTE: Longer Spin times typically reduce dryer time/energy usage (i.e. reduces total energy when using both a washer and a dryer).

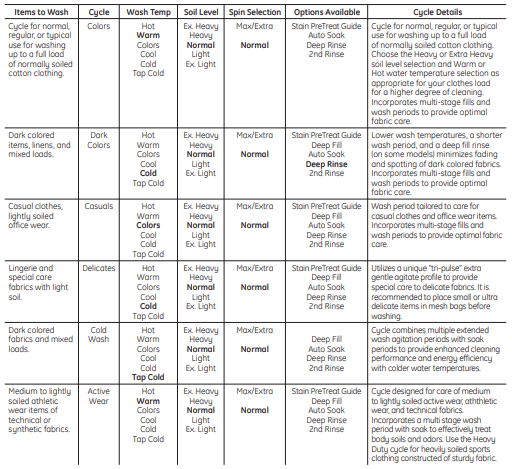

Wash Cycles-Cycle Selector Knob

Wash Cycles-Cycle Selector Knob

The wash cycle controls the type of washing process. The cycle selector knob can be turned in either direction. Turning the knob after starting a cycle will stop the washer and change the cycle/options to the new selection. Press Start to begin the new cycle selection.

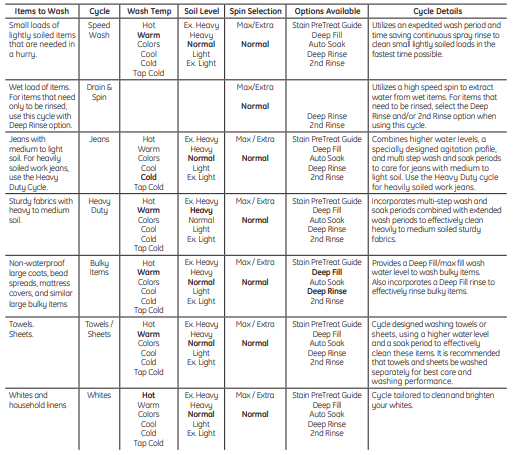

The chart below will help you match the items to be washed with the best wash cycle settings. For optimal performance, select the cycle that most closely matches the items being washed.

Selections and options shown in bold are the recommended settings for that cycle.

Some cycles and options may not be available on some models.

For waterproof, water-resistant items only use the Delicates cycle. DO NOT use other cycles for these items, for example ski clothing, diaper covers, bulky waterproof bed covers, umbrella covers, vehicle covers, sleeping bags, waterproof coats, etc).

- In other cycles different to the one recommended, when the basket turns, it is possible that water gets trapped in waterproof items and clothing, which can cause abnormal vibration. Besides, the clothing moves upwards and may be expelled, this may result in injury or damage to the washer, walls, floor, or clothing.

- DO NOT mix waterproof and non-waterproof items.

Wash Cycles-Cycle Selector Knob - Continued

Wash Cycles-Cycle Selector Knob - Continued

Cycle Options

Cycle Options

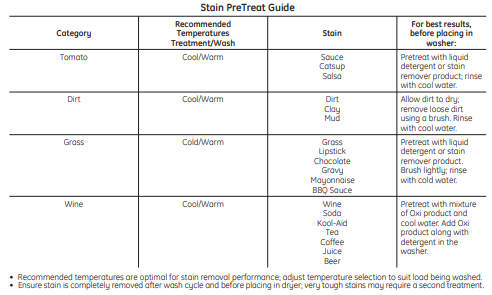

Stain PreTreat (on some models)

The Stain PreTreat feature allows you to indicate what stains are on the garments in your load. This feature incorporates a patent-pending treatment method. An initial water fill is performed at a temperature tailored to the stain type selected and to an amount which enables a concentrated cleaning step. A stain scrubbing period, followed by an active soak, is conducted to effectively treat the stain. Then additional water is added to the selected temperature and the wash phase is conducted for the cycle selected. This feature can be applied to most wash cycles as described in the cycle guide.

To use Stain PreTreat:

- Select the desired wash cycle.

- Select the stain to be treated under the Stain PreTreat options

Cycle Options - Continued

Cycle Options - Continued

Deep Fill

Select the Deep Fill feature for loads where extra water is needed.

Press the Deep Fill button once before starting the cycle to add an incremental amount of water to the wash load. Holding the deep Fill button for 3 seconds will provide the deepest fill level possible; this will increase cycle time due to the additional time it takes to fill the washer.

To cancel the option if desired, press the Deep Fill button again.

NOTE: The Deep Fill button can also be pressed after the washer has completed filling and is in the wash phase if additional water is desired. To stop the extra fill, press the Deep Fill button again and the water will stop.

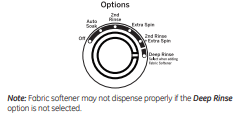

Auto Soak

This option begins with a brief agitation, soaks for a specified period of time, then moves through the rest of the cycle automatically.

2nd Rinse

When you use extra detergent or bleach to clean heavily soiled clothes, use the Rinse option to better remove additional residues.

Extra Spin

Select to provide additional spin time, increasing energy efficiency through reducing drying times.

2nd Rinse + Extra

Spin Provides both a second rinse and an extra spin.

Deep Rinse

Set this option to provide a deep rinse or when using fabric softener. This option may change other settings (e.g. Spin may go to a higher setting) to maximize performance.

Consumer Help Indicator

Your washer is equipped with Consumer Help Indicator (CHI). CHI is our way to communicate a simple remedy for some situations that you can perform without the need to call for service. The chart below describes the helpful lights you may notice flashing on the display.

About washer features.

Automatic Load Sensing (on some models)

This determines the correct agitate profile, agitate duration and amount of water suited to the size and type of load placed in the washer. The washer will not start the wash cycle or fill with water if the lid is open. When the lid is closed the machine is able to begin filling with water in order to sense the load size.

NOTE: Automatic Load Sensing initiates a spin at the beginning of the cycle and will take as much as 3 minutes to complete (significantly shorter for smaller loads); this is normal operation.

NOTE: This is a high efficiency washing machine with agitator wash action. This system requires less water while providing effective cleaning action. You may notice that the water level is lower than on your previous washer. This is normal for an agitator-equipped washer.

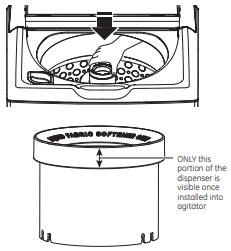

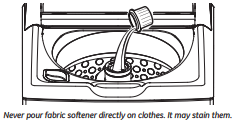

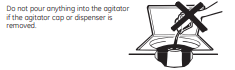

Liquid Fabric Softener Dispenser (on some models)

The agitator cap fits into the top of the agitator. If it accidentally comes off, simply put it back on.

The fabric softener dispenser automatically releases liquid fabric softener at the proper time during the cycle.

Do not stop the washer or raise the lid during the first spin. This will cause the dispenser to empty too soon.

To use, follow these steps:

- Make sure dispenser is securely attached to agitator.

- Use only liquid diluted fabric softener. Pour into dispenser, using amount recommended on package.

- Add water to dispenser until it reaches the maximum fill line

- Select Deep Rinse option

Liquid Bleach

Liquid chlorine bleach should be added through the bleach dispenser in the front left corner. Follow bleach manufacturer’s recommendations for the correct amount of liquid chlorine bleach based on load size, taking care to not apply or spill it directly on clothing.

NOTE: Do not use liquid chlorine bleach and laundry pretreatments such as an Oxi product in the same wash load.

Pretreatment

Place laundry pretreatments, such as an Oxi product, directly in the bottom of the wash basket before loading clothes.

NOTE: Do not use liquid chlorine bleach and laundry pretreatments such as an Oxi product in the same wash load.

Care and cleaning of the washer.

Exterior of the Washer

Immediately wipe off any spills with a damp cloth.

Immediately wipe off any spills with a damp cloth.

Leave the lid open after washing to allow moisture to evaporate. If you want to clean the basket, use a clean soft cloth dampened with liquid detergent; then rinse. (Do not use harsh or gritty cleaners.)

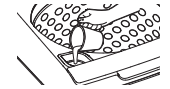

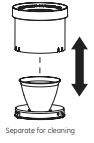

Cleaning the Fabric Softener Dispenser (on some models)

- Remove the dispenser from the top of the agitator.

- Separate the dispenser cup from the cover by grasping the top and pushing down on the inside of the cup with your fingers. Dispenser cup will pop free from the cover. To clean the dispenser, soak both the dispenser cup and the dispenser cover in the following solution

- 1 US gallon (3.8 liters) warm water

- 1/4 cup (60 ml) heavy-duty liquid detergent

- 1 cup (240 ml) bleach

- If necessary, loosen buildup with a clean, soft cloth after soaking. Do not use a stiff brush; you may roughen the surface of the dispenser.

- Rinse and reassemble dispenser. Place dispenser back on the agitator.

Water Supply Hoses

Hoses connecting washer to faucet should be replaced every 5 years

Moving and Storage

Ask the service technician to remove water from drain pump and hoses. Do not store the washer where it will be exposed to the weather.

Long Vacations

Be sure water supply is shut off at faucets. Drain all water from hoses and water filter pump area if weather will be below freezing.

Installation Instructions

BEFORE YOU BEGIN

Read these instructions completely and carefully.

- IMPORTANT – Save these instructions for local inspector’s use.

- IMPORTANT – Observe all governing codes and ordinances.

- Note to Installer – Be sure to leave these instructions with the Consumer.

- Note to Consumer – Keep these instructions for future reference.

- Skill level – Installation of this appliance requires basic mechanical and electrical skills.

- Completion time – 1-3 hours

- Proper installation is the responsibility of the installer.

- Product failure due to improper installation is not covered under the Warranty.

LOCATION OF YOUR WASHER

Do Not Install the Washer:

- In an area exposed to dripping water or outside weather conditions. The ambient temperature should never be below 60°F (15.6°C) for proper washer operation.

- In an area where it will come in contact with curtains or drapes.

- On carpet. The floor MUST be a hard surface with a maximum slope of 1/2 per foot (1.27 cm per 30 cm). To make sure the washer does not vibrate or move, you may have to reinforce the floor.

NOTE: If floor is in poor condition, use 3/4 impregnated plywood sheet solidly attached to existing floor covering.

IMPORTANT: Minimum Installation Clearances - Alcove or Closet

- If your washer is approved for installation in an alcove or closet, there will be a label on the back of the machine describing requirements.

- Minimum clearance between washer and adjacent walls or other surfaces: 0" either side, 2" front, 3" rear. Vertical space from floor to overhead shelving, cabinets, ceiling, etc. = 60".

- Closet doors must be louvered or otherwise ventilated and require 60 square inches of opening near the top of the door and 60 square inches near the bottom of the door. If a dryer is located in the same closet, then these areas must be doubled.

NOTE: The clearances stated on this label are minimums. Consideration must be given to providing adequate clearances for installing and servicing

WATER SUPPLY REQUIREMENTS

- WATER PRESSURE - Must be 20 psi minimum to 120 psi maximum.

- WATER TEMPERATURE - Household water heater should be set to deliver water at 120° to 150°F (50° to 66°C) TO THE WASHER when hot wash is selected.

- SHUTOFF VALVES - Both hot and cold shutoff valves (faucets) should be supplied.

- DRAIN - Water should be drained into standpipe. Discharge height MUST NOT BE LESS THAN 30 INCHES and no more than 8 feet above the base of the washer. Standpipe must be 1-1/2 inches minimum inside diameter and must be open to atmosphere.

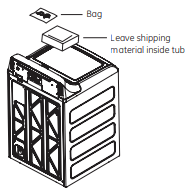

1 UNPACKING THE WASHER

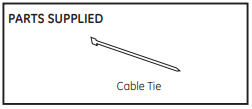

After the machine is in the home, remove outside packing material/carton from washer. Remove bag (containing cable tie, drain hose clip) and Owner’s Reference Guide from tub. .

NOTE: Leave foam shipping material inside tub opening to hold tub in place during the rest of installation.

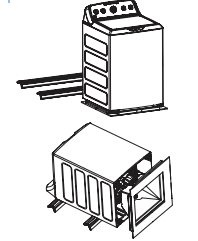

2 REMOVE THE BASE

Remove base from unit by placing foot on side of base and tipping unit back on corner post. Remove base and bring the washer back upright.

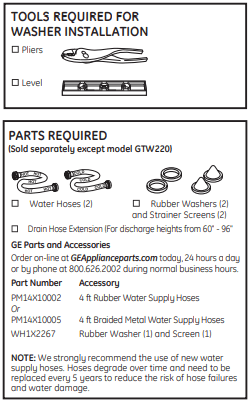

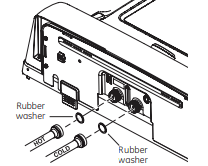

3 CONNECT WATER HOSES TO WASHER

Disconnect the electrical cord before installing water hoses. If not installed, install rubber washer in one end of the hot water hose. Thread the hot water hose onto connection labeled H at top rear of the washer. Hand tightens and use pliers to tighten hoses between 1/8 and 1/4 turn beyond hand-tight.

If not installed, install rubber washer in one end of cold water hose C. Thread cold water hose onto connection labeled C at top rear of washer. Hand tightens and use pliers to tighten hoses between 1/8 and 1/4 turn beyond hand tight.

Move washer as close to final location as, leaving room for you to make water, drain, and electrical connections to your home.

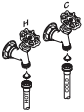

4 CONNECT WATER HOSES TO WASHER

Rubber washer Determine which is HOT water line before attaching water hoses to faucets. Traditionally, HOT faucet is on left. (If screen washers are not installed) With protruding part of screen toward you, install strainer screen/rubber washer into each of the free ends of two water hoses. Connect hot water hose to hot water outlet valve of your home. Hand tightens and use pliers to tighten hoses between 1/4 and 1/2 turn beyond hand-tight. Open hot water valve. Connect cold water hose to cold water outlet valve of your home. Hand tightens and use pliers to tighten hoses between 1/4 and 1/2 turn beyond hand-tight. Open cold water valve. Check for leaks and drips at the hose couplings. Tighten as necessary.

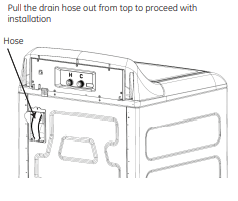

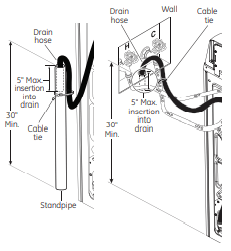

5 CONNECT TO DRAIN

The drain or standpipe must be capable of accepting a discharge at a rate of 16 gal per minute. The drain height must be 30” minimum and 96” maximum.

The standpipe diameter must be 1-1/2” minimum. There MUST be an air gap around the drain hose in the stand pipe. A snug fit can cause a siphoning action.

For a drain facility less than 33” high, the hose, coupling and clamps provided in the machine must be used and, in addition, a siphon break MUST be installed on the back of the machine. Obtain and use a siphon break kit and follow the instructions in the kit.

If water valves and drain are built into wall, fasten drain hose to one of water hoses with cable tie provided (ribbed side on inside). If your drains is a standpipe, fasten drain hose to standpipe with cable tie provided

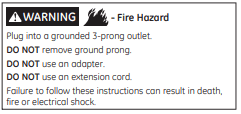

ELECTRICAL REQUIREMENTS

CIRCUIT – Individual, properly polarized and grounded 15 or 20 amp circuit breaker or time-delay fuse.

POWER SUPPLY – 2 wire plus ground, 120 Volt, single phase, 60 Hz, alternating current.

Outlet Receptacle – Properly grounded 3-prong receptacle to be located so the power cord is accessible when the washer is in an installed position. If a 2-prong receptacle is present, it is the owner’s responsibility to have a licensed electrician replace it with a properly grounded 3-prong grounding type receptacle.

Washer must be electrically grounded in accordance with local codes and ordinances, or in the absence of local codes, in accordance with the NATIONAL ELECTRICAL CODE, ANSI/NFPA NO. 70 latest edition. Check with a licensed electrician if you are not sure that the washer is properly grounded.

7 CONNECT POWER AND INSTALL

Make sure large dial control (on some models) on washer is pushed in to the OFF position.

Insert plug of electrical cord into a 115V, 15- or 20-amp wall receptacle. Move washer into final position. Place level on flat top side edges of washer. Adjust all four leveling legs until washer is level left-to-right and front-to-back. Remove level. Open tub lid. Remove and discard tub shipping material (see Step 1). Remove plastic protector sheet from control panel face.

[image]

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance to electric current. This appliance is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment grounding conductor can result in a risk of electrical shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded. DO NOT modify the plug on the power supply cord. If it will not fit the outlet, have a proper outlet installed by a qualified electrician

If required by local codes, an external 18 gauge or larger copper ground wire (not provided) may be added. Attach to washer cabinet with a #10-16 x 1/2” sheet metal screw (available at any hardware store) to rear of washer as illustrated.

[image]

Mobile Home Installation: Installation must conform to Standard for Mobile Homes, ANSI A119.1 and National Mobile Home Construction and Safety Standards Act of 1974 (PL93-383)

FINAL CHECKLIST

Before starting the washer, check to make sure:

- Main power is turned on.

- The washer is plugged in.

- The water faucets are turned on.

- The unit is level and all four leveling legs are firmly on the floor.

- The shipping foam and cardboard are removed.

- The drain hose is properly tied up.

- There are no leaks at the faucet, drain line or washer.

Run the washer through a complete cycle.

- Check for water leaks and proper operation.

- Place these instructions in a location near the washer for future reference

Before you call for service…Troubleshooting Tips

Small amount of water remaining in dispenser (on some models) at end of cycle

- Normal dispenser operation

It is normal for a small amount of water to remain in dispenser after the cycle.

Short spray and delay after pushing the Start button

- Lid was opened and closed between cycle selection and start

This is normal. See START-UP SEQUENCE in the Safety Instructions section.

Water level seems low

- This is normal

Water may not cover the top level of the clothes. This is normal for this high efficiency washer.

Low water flow

- Water valve screens are stopped up

Turn off the water source and remove the water connection hoses from the upper back of the washer and the water faucets. Clean both the hose screens (if so equipped) and the screens in the machine using a brush or a toothpick. Reconnect the hoses and turn the water back on. Check to ensure there are no leaks at the connections.

Water siphoning out of washer

- Drain standpipe is too low or hose too far into standpipe

The drain hose must exceed 32” height at some point between the washer back and the drain pipe. Use anti-siphon clip. See the Installation Instructions.

Too many suds

- Soft water

Try less detergent.

- Too much detergent

Measure your detergent carefully. Use less soap if you have soft water, a smaller load or a lightly soiled load.

- Type of detergent

Switch to High Efficiency detergent such as he

Water leaks

- Type of detergent

Switch to High-Efficiency detergent such as he

- Using too much detergent in washer

Use less detergent. Use less soap if you have soft water, a smaller load or a lightly soiled load.

- Fill hoses or drain hose is improperly connected

Make sure hose connections are tight at faucets and rubber washers are installed. Make sure end of drain hose is correctly inserted in and secured to drain facility.

- Household drain clogged

Check household plumbing. You may need to call a plumber.

- Drain hose rubs on wall

Make sure drain hose does not make contact with the wall. May cause excessive wear on the hose.

- Constant water pressure to fill hoses at water source

Tighten hoses at the faucets. Check condition of the fill hoses; they should be replaced every 5 years.

Water temperature seems incorrect

- Cooler water temperatures provide improved energy efficiency

New laundry detergents have been formulated to work with cooler water temperatures without affecting wash performance.

- Water supply is turned off or improperly connected

Turn both hot and cold faucets fully on and make sure hoses are connected to correct faucets. NOTE: Water valves are marked “H” and “C”.

- Water valve screens are stopped up

Turn off the water source and remove the water connection hoses from the upper back of the washer and the water faucets. Clean both the hose screens (if so equipped) and the screens in the machine using a brush or a toothpick. Reconnect the hoses and turn the water back on. Check to ensure there are no leaks at the connections.

- Cool/Cold Water when selecting Hot

This is normal. The washer senses water temperature (on some models) and optimizes for best results. Cold water is added periodically when hot is selected.

- House water heater is not set properly

Make sure house water heater is delivering water at 120°F–140°F (48°C–60°C).

Water pumped out before cycle is complete

- Lid lifted or cycle was put in pause for over 24 hours

Reset cycle.

Water won’t drain

- Drain hose is kinked or improperly connected

Straighten drain hose and make sure washer is not sitting on it. Top of drain outlet should be less than 6 ft (1.8 m) above floor.

Washer spins and pauses at the beginning of cycles

- This is normal

The washer is sensing the load.

Washer pauses during wash cycle

- The Soak Option was chosen

This is normal. The washer alternates between agitating and soaking during these cycles to get your clothes cleaner with less wear.

- This is normal

Many cycles incorporate a series of soaks within the agitation period to get your clothes clean with less wear

Residual powder in dispenser or clogging of dispensers (on some models)

- Wash water too cold or low home water pressure

Select a warmer wash temperature if possible to improve dissolving of detergent or use liquid detergent. Make sure siphon caps are free of debris and fully pressed into position. Remove and clean tray if clogging occurs.

Laundry additives dispensing too soon (Dispensers on some models)

- Overfilling of dispensers

Do not overfill or add water to dispenser. SelectDeep Rinse option when using fabric softener.

Washer pauses during spin cycle

- This is normal

The washer may pause during the spin cycle to remove soapy water more efficiently

Washer won’t operate

- Washer is unplugged

Make sure cord is plugged securely into a working outlet.

- Water supply is turned off

Turn both hot and cold faucets fully on.

- Lid is an open-safety feature prevents agitation and spinning when lid is up

Close lid and press Start.

- Circuit breaker/fuse is tripped/blown

Check house circuit breakers/fuses. Replace fuses or reset breaker. Washer should have a separate outlet.

- Electronics need to be reset

Unplug washer, wait 2 minutes, plug back in and press Start. Start was not pressed Press Start.

Detergent packets not dissolving

- Laundry detergent packet placed in dispenser

Laundry detergent packets should not be used in the dispensers. They should only be added directly to the wash basket following the manufacturer’s directions.

Unexplained time and/ or settings changes

- Changing options (on some models)

This is normal. Several options will change other options to maximize washer performance.

Basket seems loose

- Basket moves or rotates freely

Washer basket does not have a traditional brake. Washer basket will move freely. This is normal

Colored spots

- Incorrect use of fabric softener

Check fabric softener package for instructions and follow directions for using dispenser. Make sure you have selected the Deep Rinse option. Pretreat stain and rewash using Speed Wash cycle before drying.

- Dye transfer

Sort whites or lightly colored items from dark colors.

Grayed or yellowed clothes

- Detergent amount

Be sure to follow detergent manufacturer’s directions.

- Hard water

Use a water conditioner or install a water softener.

- Water is not hot enough

Make sure water heater is delivering water at 120°F–140°F (48°C–60°C).

- Washer is overloaded

Loosely load clothes no higher than the top row of holes in the washer basket. For best results, load items around the outside of the basket.

- Dye transfer

Sort clothes by color. If fabric label states wash separately, unstable dyes may be indicated.

Lint or residue on clothes

- Clothes are air or line dried

If you do not dry your clothes with a clothes dryer, your clothes may retain more lint.

- Incorrect sorting

Separate lint producers from lint collectors.

- Washing too long

Wash small loads for a shorter time using Light Soil setting.

- Detergent not dissolving

Rewash; next time: Try a liquid detergent Use warmer water temperature.

- Overloading

Loosely load clothes in the washer basket. For best results, load items around the outside of the basket.

- Incorrect use of fabric softener

Check fabric softener package for instructions and follow directions for using dispenser. Make sure you have selected the Deep Rinse option.

Clothes too wet

- No spin selected

Select a spin option.

- Incorrect cycle selected

Make sure the cycle selected matches the load you are washing. Some fabrics will feel wetter when rinsed with cold water.

- Wash load out of balance

Redistribute load in washer and run through Drain & Spin cycle.

Blinking Spin light or Spin light on at end of cycle

- Out of balance condition has been detected

Allow cycle to continue and finish. If load is wet at the end of the cycle, even out load and run a Drain & Spin cycle.

Pilling

- Result of normal wear on poly-cotton blends and fuzzy fabrics

While this is not caused by the washer, you can slow the pilling process by washing garments inside out.

Snags, holes, tears, rips or excessive wear

- Pins, snaps, hooks, sharp buttons, belt buckles, zippers and sharp objects left in pockets

Fasten snaps, hooks, buttons and zippers. Remove loose items like pins, objects in pockets and sharp buttons. Turn knits (which snag easily) inside out.

- Undiluted chlorine bleach

Check bleach package instructions for proper amount. Never add undiluted bleach to wash or allow clothes to come in contact with undiluted bleach.

- Chemicals like hair bleach or dye, permanent wave solution

Rinse items that may have chemicals on them before washing. Use Speed Wash cycle withExtra Rinse option.

Wrinkling

- Incorrect wash and dry cycles

Match Cycle selection to the type of fabric you are washing (especially for easy care loads).

- Improper sorting

Avoid mixing heavy items (like jeans) with light items (like blouses). Try a fabric softener.

- Overloading

Loosely load clothes in the washer basket.

- Repeated washing in water that is too hot

Wash in warm or cold water.

“Clicking”

- Shifter mechanism is engaging or disengaging

The drive system will engage at the start of agitate and disengage when agitate is complete. This occurs multiple times during the wash.

Back and forth “swoosh”

- Electric motor reversing direction

This sound is the motor rotating back and forth to clean your laundry.

“Clicking” behind Control during fill

- Automatic Temperature Control Valve

Two valves mix cold and hot water. The “clicking” is when either valve turns on or off to raise or lower the fill water temperature.

Water flow changes during fill

- Automatic Temperature Control Valve

Two valves mix cold and hot water. The “clicking” is when either valve turns on or off to raise or lower the fill water temperature.

Motor sounds during spin

- Motor ramping up/down during spin cycle

The motor will speed up incrementally during the spin cycle. When spin is complete, it will coast until it stops.

“Humming”

- Water drain pump

The drain pump will make a humming sound when pumping out water after agitation stops and continue until spin is complete.

- Drive motor

The drive motor will make a “humming” sound during the wash and spin phases of the cycle.

“Gurgling”

- Water drain pump

When the pump starts drawing in air, It starts to gurgle. The washer should then begin spinning and the sound will continue until it is done spinning.

Water “swishing”

- Washing process

Water swishing, while the unit is agitating, is normal, especially with smaller loads.

Washer rocking/ moving

- Washer leveling legs uneven

To level the washer, adjust the leveling legs by rotating the individual leg in the proper direction for up or down.

“Squeaking” sound

- Washer not level and rubbing on cabinet

To level the washer, adjust the leveling legs by rotating the individual leg in the proper direction for up or down.

See other models: GTW485BMMWS ZDWR240PABS ZDBR240PBBS GVS04BDWASS TFG25PADAWW