Loading ...

Loading ...

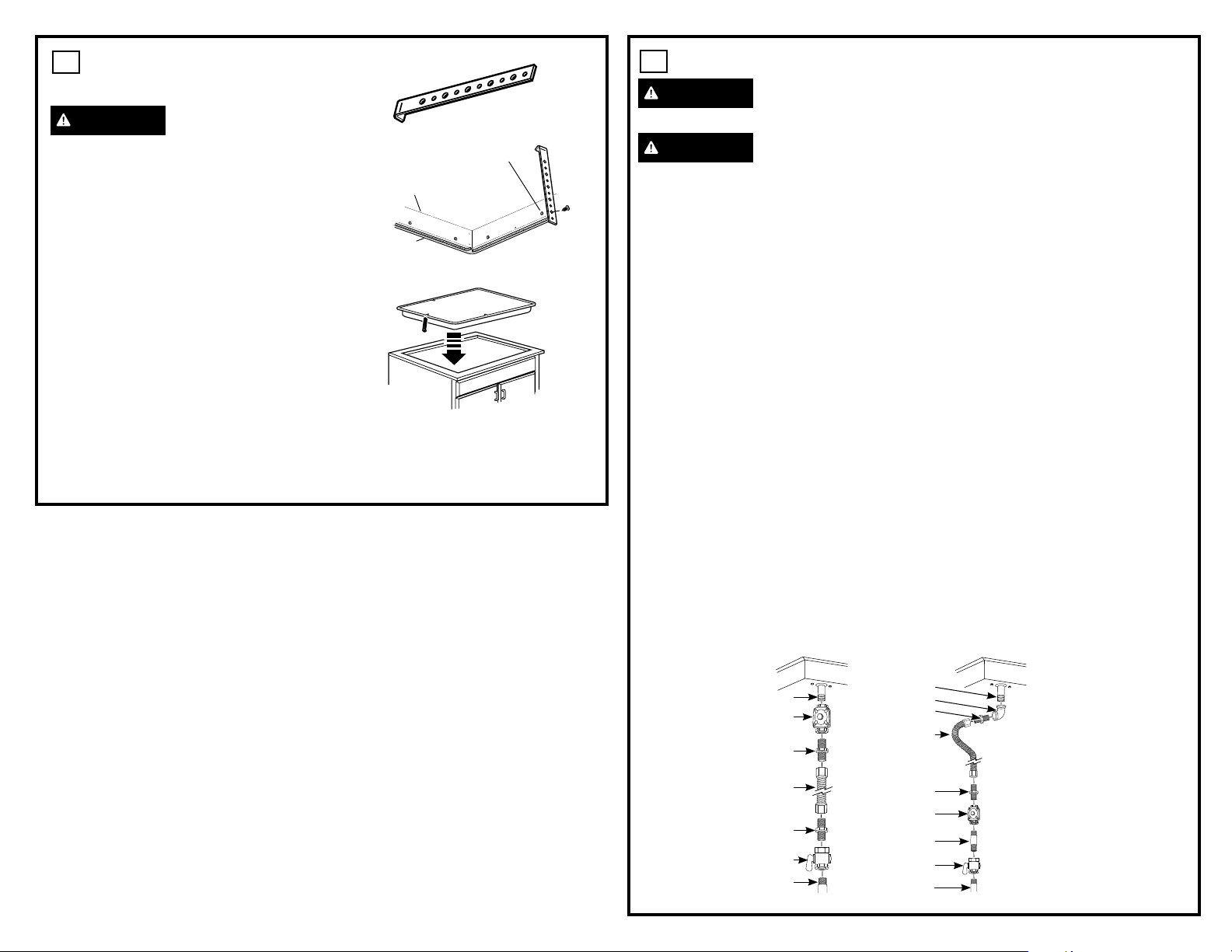

A. 3/8” NPT male pipe thread

B. E lbow

C. Adapter

D. Flexible connector (allows

passage through cabinet wall)

E. Adapter

F. Regulator provided with unit:

• Outlet - 3/8” NPT female pipe

thread

• Inlet - 1/2” NPT female pipe

thread

G. Gas pipe

H. Manual shut-off valve

I. Gas pipe 1/2” or 3/4”

1

INSTALLING THE

COOKTOP

WARNING

Do not remove the 6

black Z brackets screwed to the bottom of the

cooktop (on some models).

A. Locate electrical outlet and gas shut-off

valve beneath cabinet.

B. Lay cooktop upside down on a towel or

tablecloth covered countertop.

C. Locate and remove hold-down brackets

from literature package.

D. Attach brackets to cooktop. Remove the

screw from the side of the cooktop and

screw the hold-down bracket to the side of

the cooktop unit. Repeat for opposite side

of cooktop.

E. Insert the cooktop centered into the cutout

opening. Make sure the front edge of the

countertop is parallel to the cooktop.

Make final check that all required

clearances are met.

Once the unit is in place, screw the hold-

down bracket into the cabinet sides to

secure the unit into place.

Cooktop

Pre-drilled hole

Bottom of Cooktop

Cooktop

Surface

CONNECTOR HOOKUP

2

GAS SUPPLY

WARNING

Fire Hazard: Do not use

a flame to check for gas leaks.

WARNING

Explosion Hazard: Do

not exceed 25 ft-lbs of torque when making

gas line connections. Overtightening may

crack the pressure regulator resulting in fire

or explosion hazard.

Gas Pressure Regulator

You must use the gas pressure regulator supplied

with this range. For proper operations the inlet

pressure to the regulator should be as follows:

Natural Gas:

Minimum pressure: 6” of Water Column

Maximum pressure: 13” of Water Column

Propane Gas:

Minimum pressure: 11” of Water Column

Maximum pressure: 13” of Water Column

If you are not sure about the inlet pressure

contact local gas supplier.

Shut off the main gas supply valve before

disconnecting the old cooktop and leave it off

until the new hook-up has been completed.

Don’t forget to relight the pilot on other gas

appliances when you turn the gas back on.

Because hard piping restricts movement of

the range, the use of a CSA International-

certified flexible metal appliance connector is

recommended unless local codes require a

hard-piped connection.

If the hard piping method is used, you must

carefully align the pipe; the cooktop cannot be

moved after the connection is made.

To prevent gas leaks, apply pipe joint compound

or wrap pipe thread tape with Teflon* around all

male (external) pipe threads.

A. Install provided regulator in the gas line

between the cooktop and manual shut-off

valve. Refer to the arrow on the back of the

regulator for gas flow direction. Ensure the

front of the regulator is facing towards the

cabinet front, easily accessible through the

cabinet doors.

B. Install a manual shut-off valve in the gas line

in a location easily accessible through the

cabinet doors.

C. When all connections have been made,

ensure all gas controls are in the off position

and turn on the main gas supply valve.

Use a liquid leak detector at all joints and

connections to check for leaks in the system.

When using pressures greater than 1/2 psig

to pressure test the gas supply system of

the residence, disconnect the cooktop and

individual shut-off valve from the gas supply

piping. When using pressures of 1/2 psig or

less to pressure test the gas supply system,

simply isolate the cooktop from the gas supply

system by closing the individual shut-off valve.

When checking for proper operation of the

regulator, the inlet pressure must be at least 1”

greater than the operating (manifold) pressure

as given on rating label of product.

*Teflon: Registered trademark of DuPont

TYPICAL INSTALLATION WITH NO

OBSTRUCTION BELOW COOKTOP

ALTERNATE INSTALLATION WITH

OBSTRUCTION BELOW COOKTOP

A

B

C

D

F

G

E

A

B

C

D

F

G

E

I

H

A. 3/8” NPT male pipe

thread

B. Regulator provided with

unit:

• Outlet - 3/8” NPT

female pipe thread

• Inlet - 1/2” NPT female

pipe thread

C. Adapter

D. Flexible connector

E. Adapter

F. Manual shut-off valve

G. Gas pipe 1/2” or 3/4”

1” = 2.5 cm; 1’ = 0.3 m

Loading ...

Loading ...

Loading ...