Loading ...

Loading ...

Loading ...

www.SereneLifeHome.com

12

ROUTINE MAINTENANCE

Electrical repairs must only be carried out by a qualied or approved engineer.

Welding Cables: Regularly inspect their connections.

Torch: Regularly dean the contact tip and shroud to remove spatter that will

eventually disturb ow. Spraying the tip and shroud with anti-spatter spray can

reduce the build up of spatter. Replace the tip periodically to maintain a good

electrical contact between the tip and the wire. Blow clean dry air through the torch

liner from time to time to ensure the wire passes freely through it If this has no effect

the liner should be replaced.

Note: Ensure the torch lead is held in a straight line and fully extended when

feeding the wire through the torch, otherwise there is risk of the wire puncturing

the wire feed liner and torch hose.

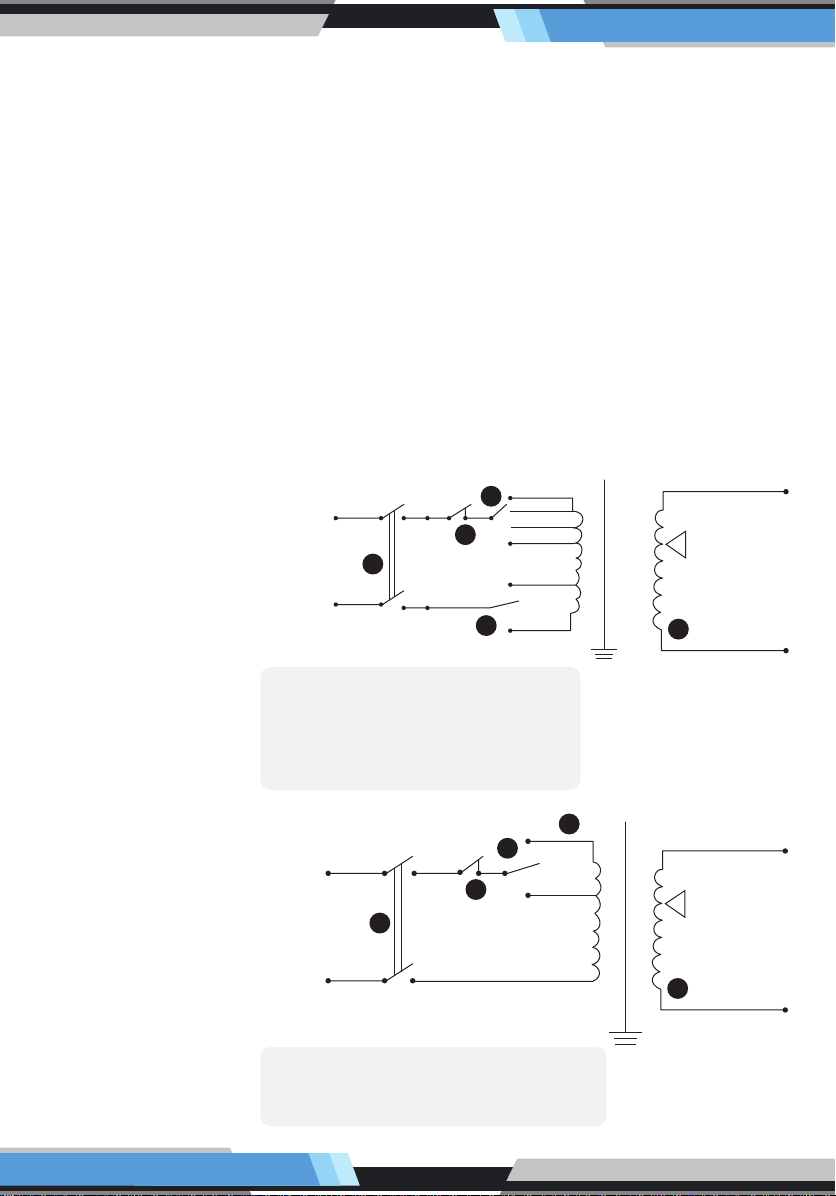

WIRING DIAGRAMS

1. Switch

2. Thermal Protection

3. Settings

4. Settings

5. Primary Winding

6. Secondary Winding

7. Rectier

1. Switch

2. Thermal Protection

3. Settings

4. Settings

5. Primary Winding

6. Secondary Winding

7. Rectier

4 POWER SETTINGS CONNECTION:

1. 230V a.d. 35A

2. 230V b.d. 50A

3. 230V a.c. 75A

4. 230V b.c. P0A

2 CURRENT SETTINGS CONNECTION:

1. a.c. PoAmp

2. a.b. boAmp

b

c

B

s1

~230V

1

a

2

3

4

30T

φ1.9

215T

φ2.4

s1

30T

φ5.25

5

s1

30T

φ5.25

5

3

2

1

4

2

3

s1

~230V

1

4

110V

220V

Loading ...

Loading ...

Loading ...