Loading ...

Loading ...

Loading ...

TROUBLESHOOTING

www.SereneLifeHome.com

11

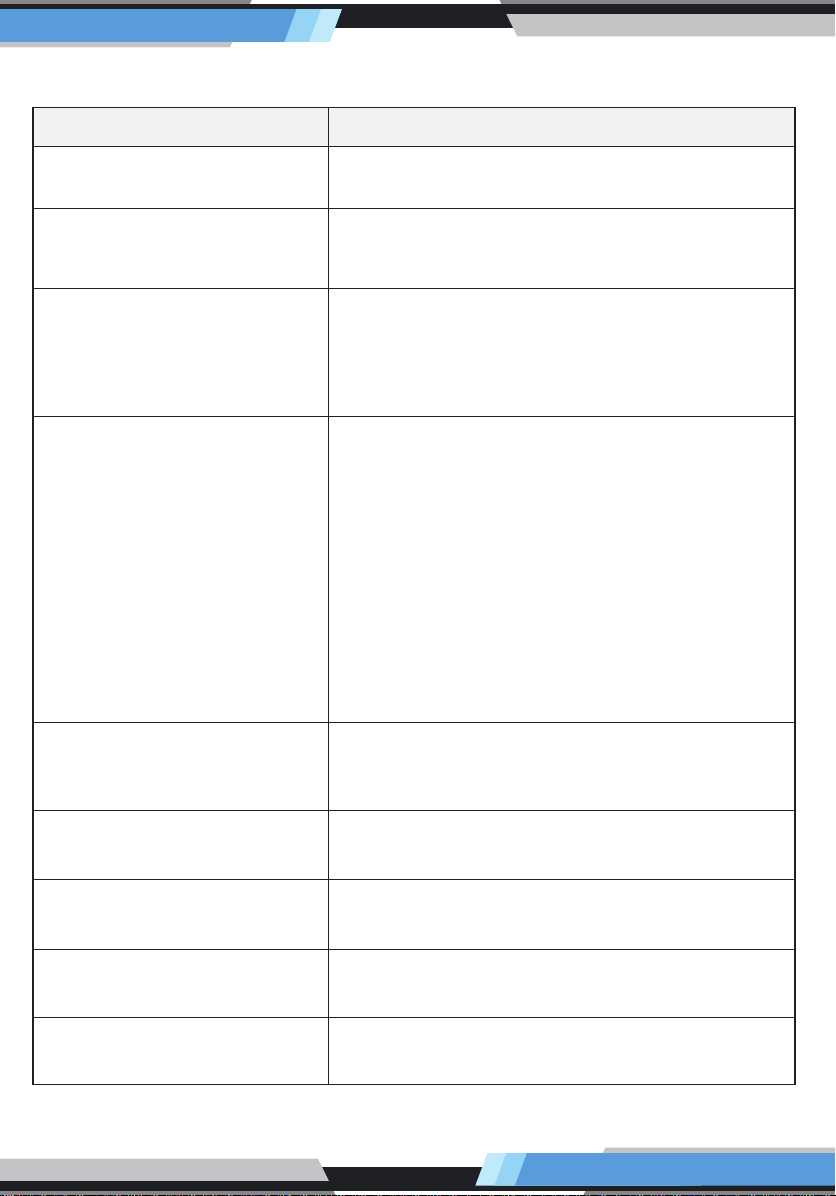

PROBLEM POSSIBLE CAUSES

Weld deposit too thick

• Welding voltage too low.

• Torch moved over the work piece too slowly.

Weld deposit incomplete

and stringy

• Torch moved over the work piece too quickly.

Rust, paint or grease on the work piece.

Arc unstable, excessive spatter

and weld porosity

• Torch held too far from the work piece.

• No gas - check bottle content, connections and

regulator settings.

• Incorrect gas for material.

Wire repeatedly burns back

• Torch held too close to the work piece.

• Break in the welding circuit

Possible causes:

• Incorrect size of contact tip for wire.

• Contact. tip damaged - replace.

• Contact tip loose - tighten.

• Feed rollers worn - replace.

• Welding wire corroded - replace.

• Pressure roller adjustment incorrect - adjust.

• Pressure roller sticking - lubricate or replace.

• Wire tangled on reel

Lack of weld penetration

• Welding output too low.

• Wire feed speed too low.

• Torch moved too fast.

Burning holes in work piece

• Welding out put too high.

• Torch moved erratically 0r too slowly.

No arc produced

• Earth lead or torch cable in open circuit.

• Poor earth clamp connection

Welder does not operate

(mains indicator not lit)

• Check mains connection.

• Check supply fuse.

Welder does not operate with

trigger pressed

• Check torch trigger and it's connecvtions.

• Thermal overload cut out - allow to cool.

Loading ...

Loading ...

Loading ...