Documents: Go to download!

User Manual

- User Manual - (English, Spanish)

- Warranty Guide - (English)

User manual Blower

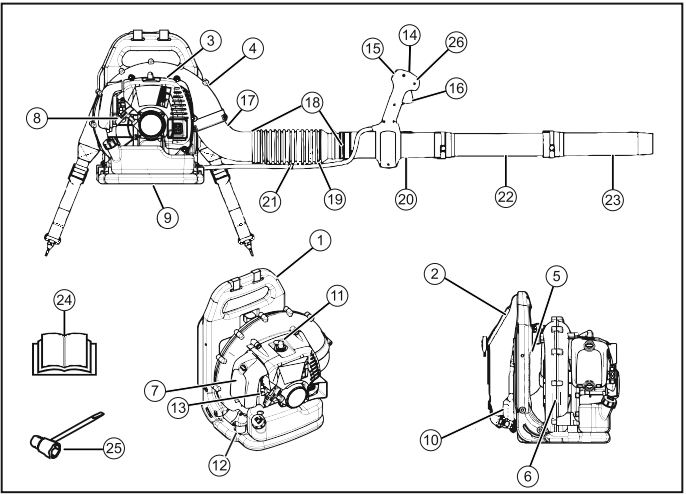

KNOW YOUR PRODUCT

NOTE: The appearance of your product may vary from the item shown.

1. Frame | 14. Operating handle |

2. Harness | 15. Stop switch |

3. Engine cover | 16. Throttle trigger |

4. Fan shell | 17. Elbow |

5. Air intake screen | 18. Clamp |

6. Fan | 19. Flexible hose |

7. Aircleaner | 20. Control pipe |

8. Starter handle | 21. Clamp for wire harness |

9. Fueltank | 22. Intermediate pipe |

10. Pad | 23. Blower nozzle |

11. Spark plug | 24. Operator’s manual |

12. Vibration damping system | 25. Combination wrench |

13. Choke control | 26. Cruise control |

ASSEMBLY

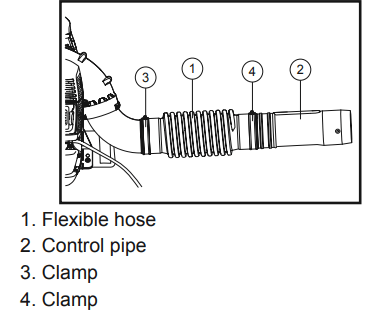

Assembling the blow pipe and control handle

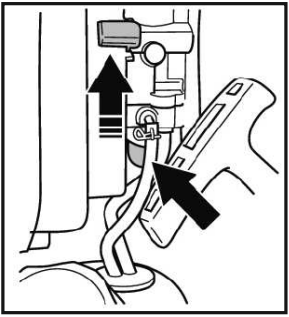

Connect the blower and control pipe with the flexible hose. Clamp both ends of the flexible hose in place.

Use the accompanying hardware.

Note! Lubricate the pipes a little to facilitate assembly.

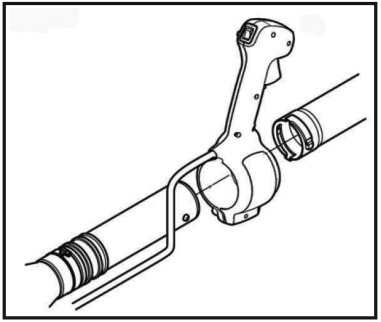

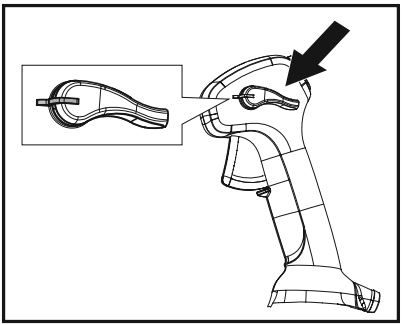

• Position the operating handle over the control pipe.

• Rotate the operating handle so that the notch passes over the tabs on the control pipe.

• Align the operating handle with the key of the control pipe.

• The cabling of the operating handle must not be twisted during assembly.

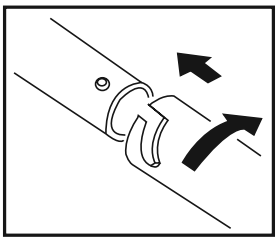

• Adjust the position to achieve a comfortable working position. Tighten the throttle handle clamp.

• Secure the cabling at the center of the flexible hose using supplied clamp.

Blower pipe

NOTE: Make sure the screws in the pipes are moved out of the way so they do not cause obstructions during assembly. Assemble the intermediate pipe and the blow pipe. Align the screws with the threaded holes in the pipes. Tighten screw upon completing assembly of blow pipes. It is possible to add more intermediate pipes if longer round blower pipe are required.

FUEL HANDLING

Fuel

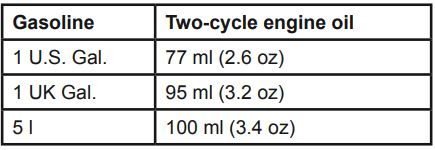

CAUTION! The machine is equipped with a twostroke engine and must always be run using a mixture of gasoline and two-stroke engine oil. It is important to accurately measure the amount of oil to be mixed to ensure that the correct mixture is obtained. When mixing small amounts of fuel, even small inaccuracies can drastically affect the ratio of the mixture.

WARNING! Always ensure there is adequate ventilation when handling fuel.

Gasoline

CAUTION! Always use high grade oil mixed gasoline (minimum 87 RON).

• This engine is certified to operate on unleaded gasoline.

• The lowest recommended octane rating is 87. If you run the engine on lower octane rating than 87 so-called “knocking" can occur. This leads to an increased engine temperature, which can result in a serious engine breakdown.

• When working at continuous high revs a higher octane rating is recommended. Use good quality unleaded gasoline.

Ethanol blended fuel, E10 may be used (max 10% ethanol blend). Using ethanol blends higher than E10 will create lean running condition which can cause engine damage.

Two-stroke oil

• For best results and performance, use a good quality fully synthetic air cooled two stroke oil at a mixture of 1:50 (2%)

• Never use two-stroke oil intended forwater-cooled outboard engines, sometimes referred to as outboard oil.

• Never use oil intended for four-stroke engines.

Mixing

• Always mix the gasoline and oil in a clean container intended for fuel.

• Always start by filling half the amount of the gasoline to be used. Then add the entire amount of oil. Mix (shake) the fuel mixture. Add the remaining amount of gasoline.

• Mix (shake) the fuel mixture thoroughly before filling the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a time.

• If the machine is not used for some time the fuel tank should be emptied and cleaned.

• This engine is certified to operate on unleaded gasoline.

Fueling

WARNING! Taking the following precautions, will lessen the risk of fire:

- Refuel in a well ventilated area. Never fuel the machine indoors.

- Do not smoke or place hot objects near fuel.

- Always shut off the engine before refueling.

- Always stop the engine and let it cool for a few minutes before refueling.

- When refuelling. open the fuel cap slowly so that any excess pressure is released gently.

- Tighten the fuel cap carefully after refueling.

- If you have spilled fuel on it. Wipe off the spillage and allow remaining fuel to evaporate.

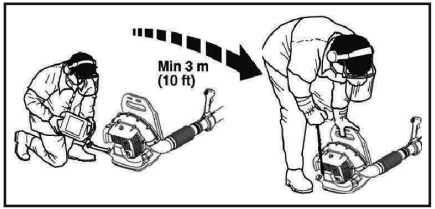

- Always move the machine away from the refueling area and source before starting.

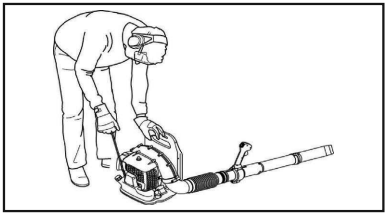

- Move the machine at least 10 ft (3 m) from the refuelling point before starting it.

- Clean the area around the fuel cap. Contamination in the tank can cause operating problems.

- Ensure that the fuel is well mixed by shaking the container before filling the tank.

- Check the fuel level before each use and leave space for the fuel to expand, because the heat from the engine and the sun may otherwise cause the fuel to expand and overflow.

STARTING AND STOPPING

Starting and stopping

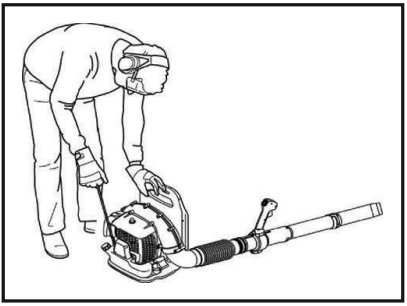

WARNING! Always move the machine away from the refueling area and source before starting. Place the machine on a flat surface.

Make sure no unauthorized persons are in the working area, otherwise there is a risk of serious personal injury. The safety distance is 15 meters (50 ft.).

The machine may only be started in its complete design. If the machine is started without all the guards fitted there is a risk of personal injuries.

Starting reminder decal

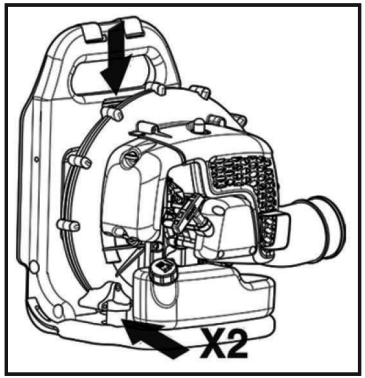

Cold engine

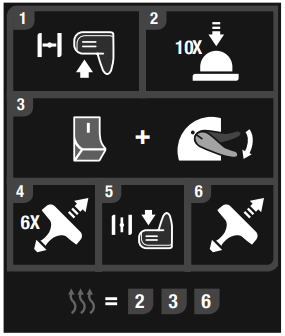

1. Set the choke control to maximum choke position.

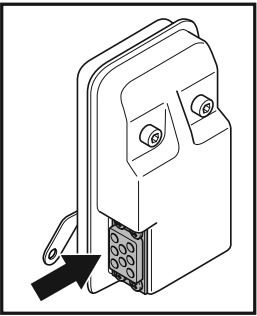

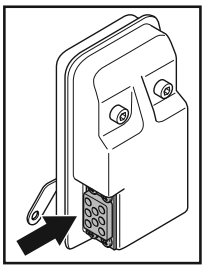

2. Press the air purge 10 times. The bulb need not be completely filled.

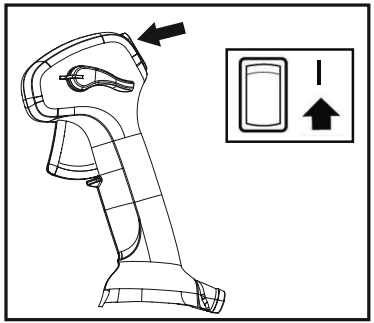

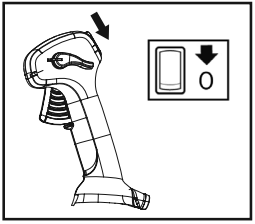

3. Set the stop switch to the start position.

4. Set cruise control lever to fast idle position using guide marks on cruise control lever and operating handle.

5. Hold the body of the machine on the ground using your left hand (CAUTION! Not with your foot!).

6. Grip the starter handle, slowly pull out the cord with your right hand until you feel some resistance (the starter pawls grip). Never wrap the starter cord around your hand.

7. Pull the starter rope quickly and powerfully 6 times.

CAUTION! Do not pull the starter cord all the way out and do not let go of the starter handle when the cord is fully extended. This can damage the machine.

8. Place choke lever to full open position.

9. Pull the starter rope sharply until the engine starts.

10. Allow engine to run at fast idle for 30 seconds. Air is released as soon as the engine is started, even when idling. Do not allow anyone to stand close to the blower or the blower tube.

Warm engine

1. Press the air purge repeatedly for a minimum of 10 times and fuel begins to fill the bulb. The bulb need not be completely filled.

2. Set the stop switch to the start position.

3. Set cruise control lever to fast idle position using guide marks on cruise control lever and operating handle.

4. Pull the starter rope sharply until the engine starts.

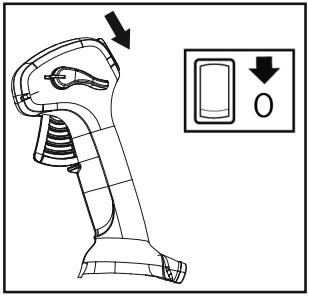

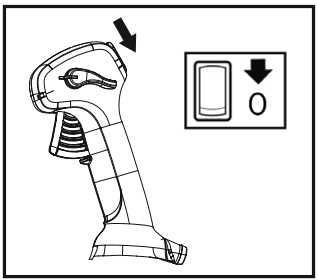

Stopping

The engine is stopped by moving the stop switch to the stop position.

MAINTENANCE

General

Remove the ignition cable and the spark plug to carry out inspection and maintenance. Keep all parts of your body away from hot surfaces.

Carburetor

Adjustment of the idle speed

Before any adjustments are made, make sure that the air filter is clean and the air filter cover is fitted. The factory idle speed setting is: 2500 rpm Use the adjustment screw at the upper edge of the carburetor if the idle speed has to be adjusted.

Muffler

The muffler is designed to reduce the noise level and to direct the exhaust gases away from the operator. The exhaust gases are hot and can contain sparks, which may cause fire if directed against dry and combustible material.

The muffler on your machine is equipped with a spark arrestor screen. NOTE: THE SPARK ARRESTOR SCREEN ON THIS UNIT IS NOT SERVICEABLE. As your unit is used, carbon deposits build up on the muffler and spark arresting screen. For normal homeowner use, however, the muffler and spark arresting screen will not require any service. After 50 hours of use, we recommend that your muffler be serviced or replaced by your authorized service dealer.

CAUTION! Never use a machine with a defective muffler. Check regularly that the muffler is complete and secured correctly.

Make sure that the spark arrester and the exhaust duct are screwed in place correctly.

WARNING! The muffler gets very hot during use and remain so for some time after stopping. This also applies at idle speed. Contact can result in burns to the skin. Remember the risk of fire!

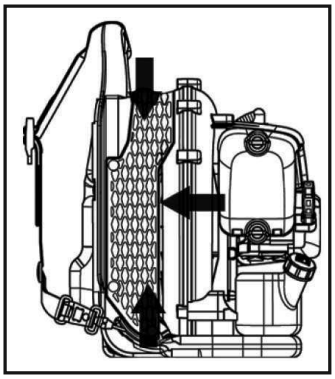

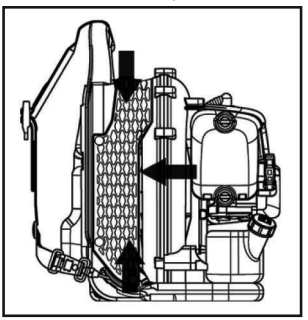

Cooling system

To keep the working temperature as low as possible the machine is equipped with a cooling system.

The cooling system consists of:

• Cooling fins on the cylinder.

• Air intake screen

Clean the cooling system with a brush once a week, more often in demanding conditions. A dirty or blocked cooling system results in the machine overheating which causes damage to the piston and cylinder. Check that the nozzles are not blocked.

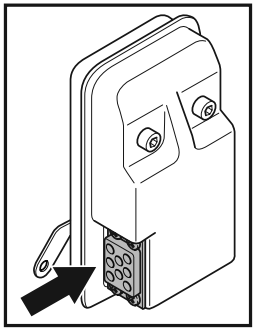

Air intake screen

Check that the air intake is not blocked on all sides including the underside, for example, by leaves or rubbish. A clogged air intake reduces the machine’s blowing capacity and increases the engine’s working temperature, which can result in engine failure. Stop the engine and remove the object.

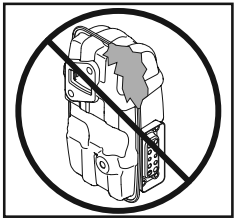

WARNING! Never use the blower if the screen is not in place. Before use, check that the screen is in place and undamaged.

Spark plug

The spark plug condition is influenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or incorrect type of oil).

• A dirty air filter.

These factors cause deposits on the spark plug electrodes, which may result in operating problems and starting difficulties.

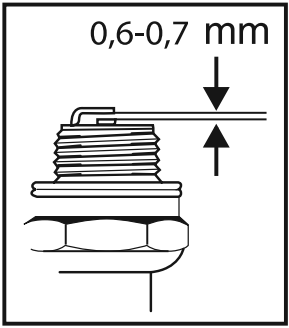

Clean the outside ofthe spark plug. Remove it and check the electrode gap. Adjust the gap to 0,6-0,7 mm, or replace the spark plug. Check that the spark plug is fitted with a suppressor.

CAUTION! Always use the recommended spark plug type! Use of the wrong spark plug can damage the piston/cylinder.

Always use the recommended spark plug type (NGK BPMR7A)! Use of the wrong spark plug can damage the piston/cylinder.

Air filter

The air filter must be regularly cleaned to remove dust and dirt in order to avoid:

• Carburetor malfunctions.

• Starting problems.

• Loss of engine power.

• Unnecessary wear to engine parts

• Excessive fuel consumption. Check the air filter and clean it when it's necessary.

Avoid contact with hot surfaces on muffler, cylinder etc. Contact can result in burns to the skin.

Cleaning the air filter

• Remove the air filter cover and take out the filter. Wash it clean in warm, soapywater.

• Refit the air filter and air filter cover. Do not forget to put the air screen back in place. If the grill is missing, the air cleaner is not properly sealed, and dust can get into the cylinder.

An air filter that has been in use for a long time cannot be cleaned completely. The filter must therefore be replaced with a new one at regular intervals. A damaged air filter must always be replaced.

If the machine is used in dusty conditions the air filter should be soaked in oil. See instructions under the heading Oiling the air filter.

Oiling the air filter

Always use special filter oil. Filter oil contains a solvent to make it spread evenly through the filter. You should therefore avoid skin contact.

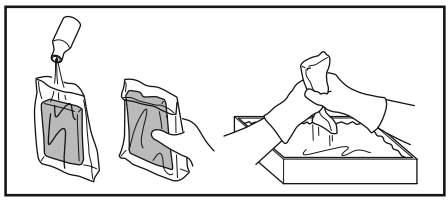

Put the filter in a plastic bag and pour the filter oil over it. Knead the plastic bag to distribute the oil. Squeeze the excess oil out of the filter inside the plastic bag and pour off the excess before fitting the filter to the machine. Never use common engine oil. This would drain through the filter quite quickly and collect in the bottom.

Shoulder strap

If the shoulder strap is damaged, it may break while in use and the machine may fall causing personal injury. Follow the instructions below to replace the shoulder strap.

1. Remove the clamp from the strap.

2. Run the end of the strap through the hanger.

3. Refit the clamp to the strap.

WARNING! Check that the thick round pin in the clamp is inserted in the strap. If it is inserted incorrectly it may lead to personal injury.

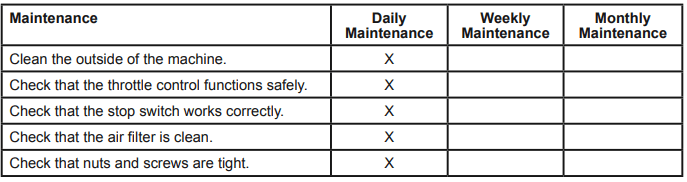

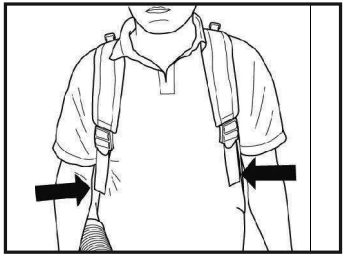

Maintenance schedule

Below you will find some general maintenance instructions. Ifyou need further information please contact your service workshop.

Contact authorized service dealer for muffler service or replacement every 50 hours.

SAFETY

Note the following before starting:

Please read the operator’s manual carefully.

WARNING! Long-term exposure to noise can result in permanent hearing impairment. So always use approved hearing protection.

WARNING! A blower is a dangerous tool if used carelessly or incorrectly and can cause serious, even fatal injuries. It is extremely important that you read and understand the contents of this Operator’s manual.

NOTE! The appearance of your product may vary from the item shown in manual.

The machine is only designed for blowing lawns, pathways, asphalt roads and the like.

Do an overall inspection of the machine before use, see maintenance schedule.

Never use the machine if you are tired, if you have drunk alcohol, or if you are taking medication that could affect your vision, your judgement or your coordination.

Wear personal protective equipment. See instructions under the heading "Personal protective equipment”.

Never use a machine that has been modified in any way from its original specification.

Never use a machine that is faulty. Carry out the safety checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried out by trained and qualified specialists. See instructions under the heading Maintenance.

All covers and guards must be fitted before starting. Ensure that the spark plug cap and ignition lead are undamaged to avoid the risk of electric shock.

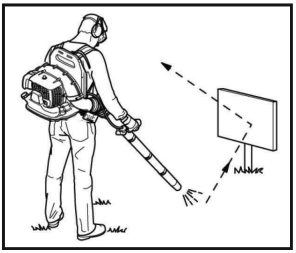

The blower operator must make sure that no bystanders or animals come nearer than 15 meters (50 feet). Whenever several operators are working in the same work area, they should maintain a safe distance of at least 15 meters (50 feet) from one another.

Never allow children to use the machine.

Never allow anyone else to use the machine

without first ensuring that they have read and understood the contents of the operator’s manual. Always check for any objects that may block the air intake screen before beginning work.

Never remove the air intake screen.

In case of emergency, release yourself from the machine by opening the waist and chest belt and let the machine fall backwards.

Always contact local authorities and make sure you are following applicable directives.

Keep all parts ofyour body away from hot surfaces.

Never touch the spark plug or ignition cable while the engine is running.

WARNING! This machine produces an electromagnetic held during operation.

This field may undersome circumstances interfere with active or passive medical implants. To reduce the risk of serious or fatal injury, we recommend persons with medical implants consult their physician and the medical implant manufacturer before operating this machine.

Starting

• Never start the machine indoors. Exhaust fumes can be dangerous if inhaled.

WARNING! Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. For this reason you should not start or run the machine indoors, or anywhere that is poorly ventilated.

• Observe the surroundings and ensure that no people or animals can come into contact with the blower.

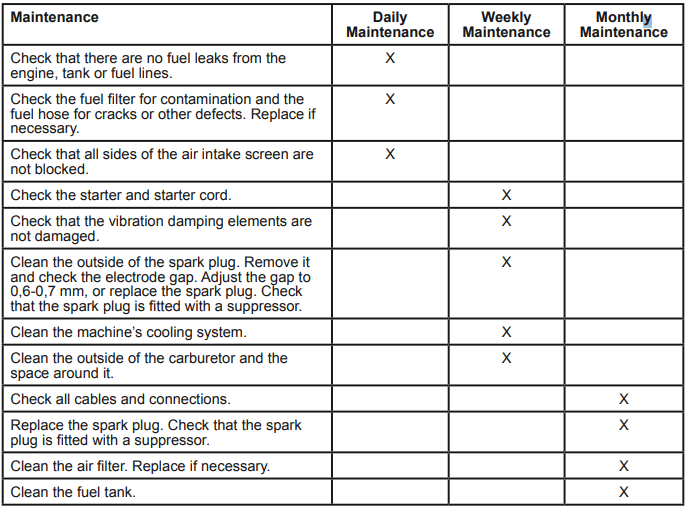

• Place the machine on the ground, press the machine body against the ground with your left hand (NOTE! Not your foot). Now grasp the starter handle with your right hand and then pull quickly and firmly. •

Fuel safety

• Always use a fuel container with an anti-spill valve.

• Never refuel the machine while the engine is running. Always stop the engine and let it cool for a few minutes before refueling.

• Make sure there is plenty of ventilation when refuelling or mixing fuel (gasoline and 2-stroke oil).

• Avoid all skin contact with fuel. Fuel is a skin irritant and may even cause skin changes.

• Move the machine at least 3 meters (10 feet) from the refuelling point before starting it.

• Never start the machine if you have spilled fuel on it. Wipe off the spillage and allow remaining fuel to evaporate.

• If you have spilled fuel on yourself for your clothes, change your clothes. Wash any part of your body that has come in contact with fuel. Use soap and water.

• If the machine is leaking fuel. Check regularly for leaks from the fuel cap and fuel lines.

Transport and storage

• Store and transport the machine and fuel so that there is no risk of any leakage or fumes coming into contact with sparks or open flames, for example, from electrical machinery, electric motors, electrical relays/switches or boilers.

• When storing and transporting fuel always use approved containers intended for this purpose.

• When storing the machine for long periods the fuel tank must be emptied. Contact your local gas station to find out where to dispose of excess fuel. Empty the fuel tank and press the primer until all fuel has been emptied.

• Remove the spark plug and drop a spoon of 2-stroke oil in the cylinder. Turn over the engine a few times and then put the spark plug back in place.

• Ensure the machine is cleaned and that a complete service is carried out before long-term storage.

• Secure the machine during transport.

• Store the machine in a dry, cool, well-aired and dust-free location. Store the machine out of reach of children.

WARNING! Take care when handling fuel. Bear in mind the risk of fire, explosion and inhaling fumes.

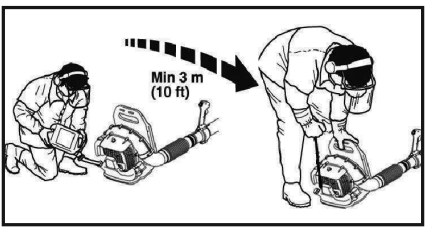

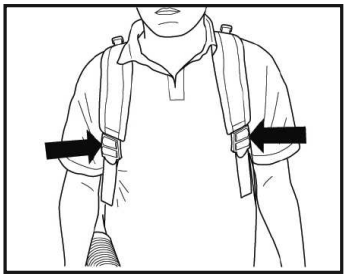

Adjusting the harness

WARNING! The harness must always be worn when working with the machine. Failure to do so means you will be unable to maneuver safely and this can result in injury to yourself or others.

A correctly adjusted harness and machine significantly facilitates the work. Adjust the harness to give the best working position.

Tighten the side straps so that the pressure is evenly distributed across the shoulders.

Lift the tabs of the sliding adjusters.

Personal protective equipment

WARNING! You must use approved personal protective equipment whenever you use the machine. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your dealer for help in choosing the right equipment. Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

WARNING! Listen out for warning signals or shouts when you are wearing hearing protection. Always remove your hearing protection as soon as the engine stops.

• Gloves should be worn when necessary.

• Wear hearing protection that provides adequate noise reduction.

• Always wear approved eye protection. If you use a visor then you must also wear approved protective goggles. Approved protective goggles must comply with standard ANSI Z87.1 in the USA or EN 166 in EU countries. Blows from branches or objects that are thrown can damage the eyes.

• Wear sturdy, non-slip boots.

• Always wear heavy, long pants, boots, gloves, and a long-sleeve shirt. To reduce the risk of injury associated with objects being drawn into rotating parts, do not wear loose clothing, scarves, jewelry, etc. Secure hair so it is above shoulder level.

• A breathing mask should be used when there is a risk of dust.

• Always have a first aid kit nearby.

Machine’s safety equipment

This section describes the machine's safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the "Know Your Product” section to locate where this equipment is positioned on your machine.

WARNING! Never use a machine that has faulty safety equipment! Carry out the inspection, maintenance and service routines listed in this section.

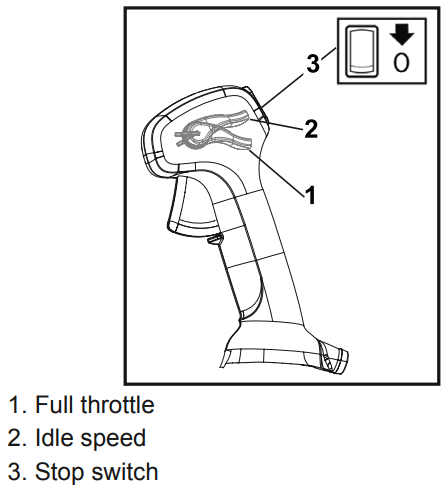

Stop switch

Use the stop switch to switch off the engine.

Remove the ignition cable and the spark plug to carry out inspection and maintenance.

Vibration damping system

Your machine is equipped with a vibration damping system that is designed to reduce vibration and make operation easier.

WARNING! Overexposure to vibration can lead to circulatory damage or nerve damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. Such symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin colour or condition. These symptoms normally appear in the fingers, hands or wrists. The risk increases at low temperatures.

Muffler

The muffler is designed to keep noise levels to a minimum and to direct exhaust fumes away from the user.

In countries that have a warm and dry climate there is a significant risk of fire. Consequently, we have equipped the muffler with a spark arrestor screen mounted inside the muffler.

For mufflers it is very important that you follow the instructions on checking, maintaining and servicing your machine. See instructions under the heading Checking, maintaining and servicing the machine’s safety equipment.

WARNING! The exhaust fumes from the engine are hot and may contain sparks which can start a fire. Never start the machine indoors or near combustible material!

WARNING! The inside of the muffler contain chemicals that may be carcinogenic. Avoid contact with these elements in the event of a damaged muffler.

Checking, maintaining and servicing the machine's safety equipment

WARNING! All servicing and repair work on the machine requires special training. This is especially true of the machine's safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

Stop switch

Start the engine and make sure the engine stops when you move the stop switch to the stop setting.

Vibration damping system

Check the vibration damping units regularly for cracks or deformation. Replace them if damaged. Check that the vibration damping element is undamaged and securely attached.

Muffler

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to the machine.

The muffler on your machine is equipped with a spark arrestor screen. NOTE: THE SPARK ARRESTOR SCREEN ON THIS UNIT IS NOT SERVICEABLE. As your unit is used, carbon deposits build up on the muffler and spark arresting screen. For normal homeowner use, however, the muffler and spark arresting screen will not require any service. After 50 hours of use, we recommend that your muffler be serviced or replaced by your authorized service dealer. A blocked screen will cause the engine to overheat and may lead to serious damage. Never use a mufflerwith a defective spark arrestor screen.

Never use a muffler with a defective spark arrestor screen.

WARNING! Never use a machine with faulty safety equipment. The machine's safety equipment must be checked and maintained as described in this section. If your machine fails any of these checks contact your service agent to get it repaired.

Air filter

Never use the leaf blower without an air filter or with a damaged or deformed filter element as unfiltered, dusty air can quickly destroy the engine.

General working instructions

IMPORTANT! This section considers basic safety rules when working with blowers.

If you encounter a situation where you are uncertain how to proceed you should ask an expert. Contact your dealer or your service workshop. Avoid all usage which you consider to be beyond your capability.

Show consideration to persons in your surroundings by avoiding using the machine at unsuitable times, such as late in the evening or early in the morning. To reduce sound levels, limit the number of pieces of equipment used at any one time. Read through and follow the simple directions so that you disturb your surroundings as little as possible.

• Use the blower with the lowest possible throttle. It is seldom necessary to use full throttle, and many work procedures can be done at half throttle. A lower throttle means less noise and less dust, and it is also easier to keep control over the rubbish collected together/moved.

• Use a rake or a brush to release rubbish stuck to the ground.

• Hold the opening of the blower as close to the ground as possible. Utilise the entire length of the blow pipe to keep the air current close to the ground.

• Clean up afterwards. Make sure that you have not blown rubbish into someone’s garden.

• Operate power equipment only at reasonable hours, not early in the morning or late at night when people might be disturbed. Complywith times listed in local ordinances.

WARNING! Be aware of your surroundings. If anyone approaches your work area, set the throttle control to the lowest throttle until the person is at a safe distance. Direct the blower away from people, animals, play areas, open windows and cars etc.

Basic safety rules

• No unauthorised persons or animals may be present in the working area, which is 15 meters (50 feet).

• Allow the engine to cool before refueling.

• Keep all parts of your body away from hot surfaces.

• If the machine catches fire or other emergency occurs which forces you to release yourselffrom the machine, open the harness straps and let the machine fall backwards.

• The powerful currents ofair can move objects at such a speed that they can bounce back and cause serious eye injuries.

• Do not direct the air jet towards people or animals.

• Stop the engine before assembling or dismantling accessories or other parts.

• Do not use the machine in bad weather, such as dense fog, heavy rain, strong wind, intense cold, etc. Working in bad weather is tiring and can lead to dangerous conditions, e.g. slippery surfaces.

• Minimize the blowing time by lightly wetting dusty areas or using spray equipment.

• Make sure you can move and stand safely. Check the area around you for possible obstacles (roots, rocks, branches, ditches, etc.) in case you have to move suddenly. Take great care when working on sloping ground.

• Never put the machine down with the engine running unless you have it in clear sight.

• Engine exhaust fumes contain carbon monoxide, which can cause carbon monoxide poisoning. For this reason you should not start or run the machine indoors, or anywhere that is poorly ventilated.

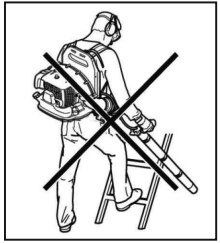

• The operator’s manual should warn that work from ladders or high places (such as roofs) is prohibited and could result in severe injury.

CAUTION! Do not use the machine unless you are able to call for help in the event of an accident.

Basic working techniques

WARNING! Watch out for thrown objects. Always wear eye protection. Stones, rubbish, etc. can be thrown up into the eyes causing blindness or serious injury. Keep unauthorised persons at a distance. Children, animals, onlookers and helpers should be kept outside the safety zone of 15 meters (50 feet). Stop the machine immediately if anyone approaches.

WARNING! Don't operate the blower if the exhaust gas outlet on the engine cover is covered by a wall and/or some other obstacles, the machine could get damage. Make sure that the distance is 50 cm (20 in) or more from the obstacles during operation.

WARNING! Always stop the engine before cleaning.

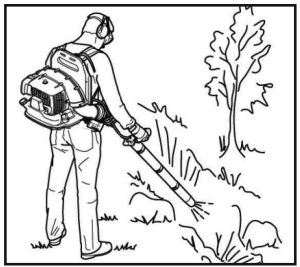

• This blower is a backpacktype, and is carried using a shoulder harness while operating. It is operated and controlled with the handle on the tube using the right hand.

• The speed ofthe airjet is regulated by means ofthe throttle. Select the speed best suited for respective tasks.

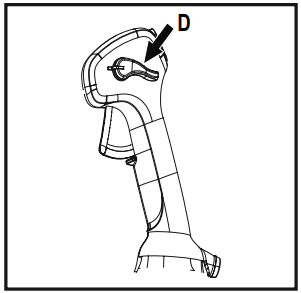

To avoid holding your finger on the throttle all the time when using the blower, the required throttle can be set with the cruise control (D). Full throttle is obtained when the throttle trigger is pushed in or the cruise control is pushed down fully.

• Check that the air intake is not blocked, for example, by leaves or rubbish. A clogged air intake reduces the machine’s blowing capacity and increases the engine’s working temperature, which can result in engine failure. Stop the engine and remove the object.

- Be aware of the wind direction. Work with the wind to make your work easier.

- Using the blower to move large piles is time consuming and creates unnecessary noise.

- Keep a good balance and a firm foothold.

- When work is finished the machine should be stored vertically.

See other models: CMCCS660E1 CMECS600 CMCCS620M1 CMCCSP20M1 41CY4218793