Loading ...

Loading ...

Loading ...

11

GAS CONVERSION

WARNING!

Isolate the appliance’s gas and electricity supplies

before performing any maintenance.

The gas conversion procedure involves two steps:

• Replacing the nozzles

• Burner minimum adjustment

WARNING: After performing the above-mentioned

procedures, the technician must apply the label

corresponding to the new gas regulation to replace

the old one. This label is contained in the bag of

spare nozzles.

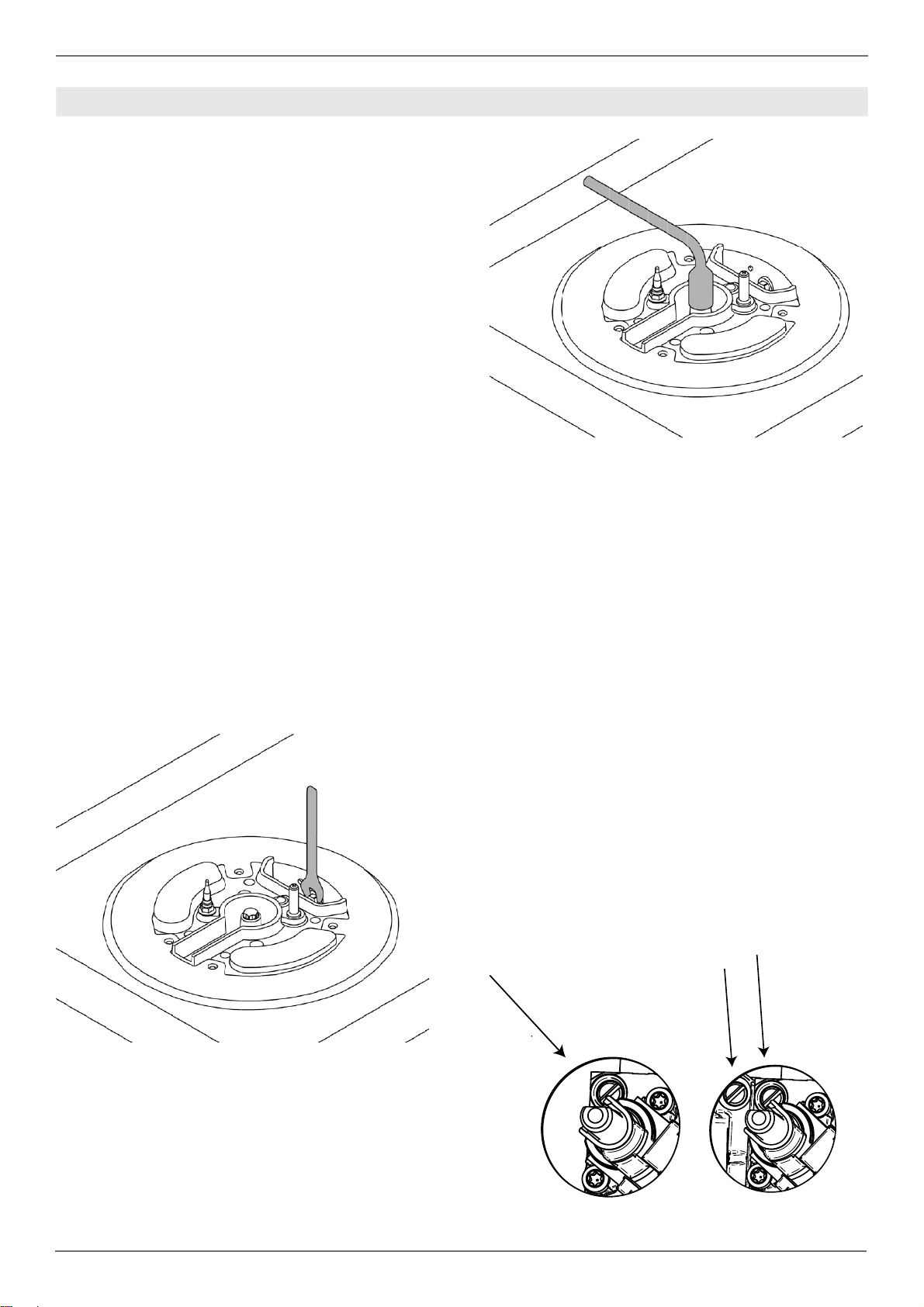

Step 1: Replacing the nozzles

Proceed as follows to change the burner nozzles:

lift the fl ame spreaders and unscrew the nozzles

using a 7 mm spanner, then replace them with

those required for new gas in accordance with the

TABLE (each nozzle has the number indicating its

diameter stamped on its body).

Keep the old nozzles in case they are required in

future.

Step 2: Burner minimum adjustment

Light the nozzle and turn the knob to the MINIMUM

position (small fl ame).

2) Remove the knob, which is simply friction fi tted

to the spindle.

3) Use a small screwdriver on the gold screw next

to the knob shank (see fi gure) and turn the fl ow

control screw to the left or right until the burner

fl ame is suitably regulated to the MINIMUM

setting.

For dual burner knobs there are two fl ow control

screws: screw A to adjust the inner ring, and screw

B to adjust the outer ring.

4) Ensure that, when moving from the MAXIMUM

to the MINIMUM position, the fl ame does not go

out.

WARNING: The above-mentioned regulation

must only be performed for burners running on

natural gas (methane): when using LPG (butane

or propane), the screw must be locked all the way

to the right.

/ Gas conversion

A

B

Loading ...

Loading ...

Loading ...