Loading ...

Loading ...

Loading ...

13

Directions for use

• Automatic controls are safety devices and shall not

be opened. The manufacturer’s responsibility and

guarantee are invalid if the control is unduly opened.

• A regulation shutdown must occur every 24hours to

enable the unit to check its own efficiency (systems

for non permanent operation)

• Connect and disconnect the unit only after switching

off the power supply

• Avoid exposing the unit to dripping water

• Ventilation and the lowest temperature ensures the

longest life of the control Electrical Installation

• Live and Neutral should be connected correctly; a

mistake could cause a dangerous situation.

• Before starting the system check cables carefully for

incorrect installation

• The earth terminal of the control, the metal frame of

the burner and the earth on the mains supply must

be well connected

Operation

At every start, the control unit proceeds to a self-checking

of its own components. During the pre-purge or waiting

time (TW) the internal circuit makes a test of the flame

signal amplifier. Extraneous light or fault in the amplifier

will result in the simulation of a flame which will prevent

the control from starting.

At the end of the waiting or pre-purge time, the gas valve

is energised and the ignition device is operated. In this

way, the safety time (TS) begins.

If a flame is detected during the safety time, the ignition

device is inhibited and the gas valve remains energised.

If the control does not detect any flame signal during

the safety time, at the end of safety time (TS), the unit

proceeds to lockout and the gas valve and ignition device

are switched off.

If the established flame signal is lost, (during the safety

time or during operation thereafter) this will cause the

ignition device to be reactivated within 1 second.

If the burner does not light within 25 seconds of ignition

reactivation, the heater will enter failure lockout mode and

must be reset.

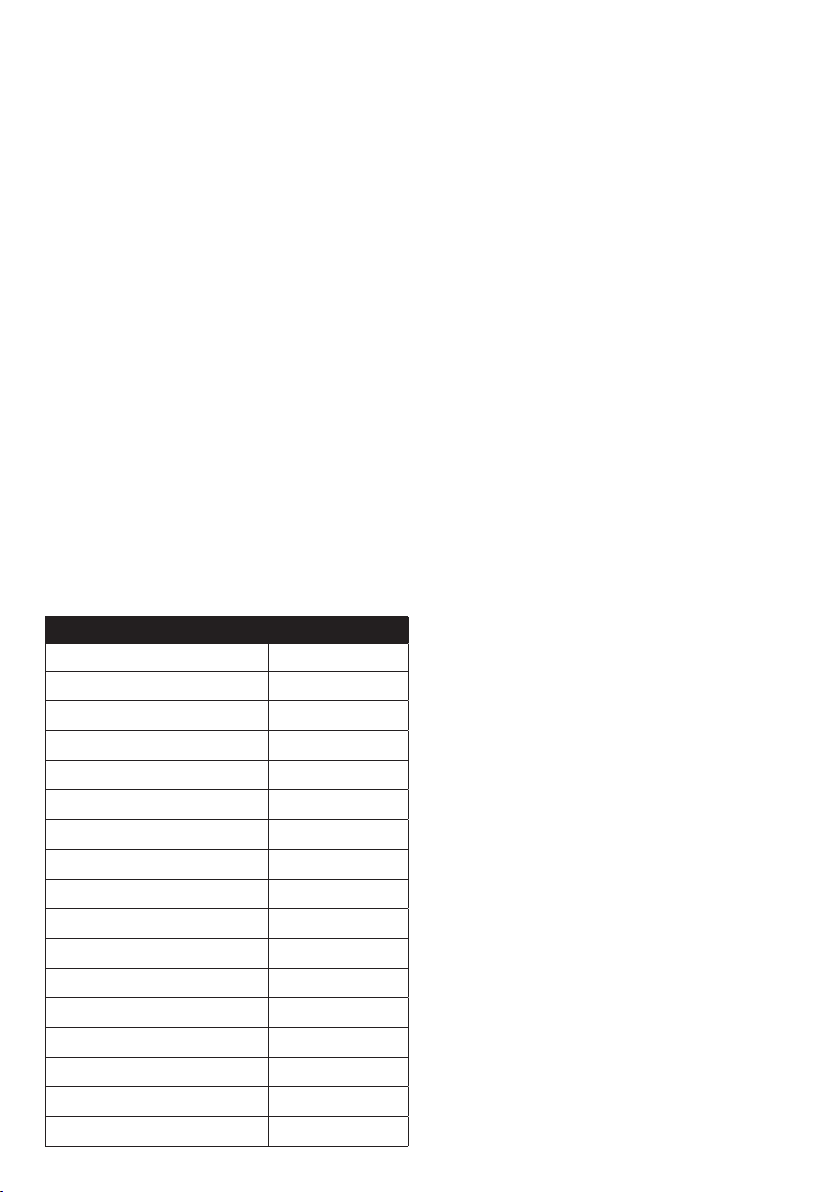

OPERATION DATA -

HONEYWELL CONTROL BOX

The following operation sequence is valid only where the

components are installed according to the manufactures

assembly and installation instructions. Please do not

modify the wiring configuration, gas train or any other part

of the heater assembly.

Application

The Honeywell electronic gas burner control system is

suitable for atmospheric gas burners for non-permanent

operation.

Although the Honeywell unit is available non volatile

lockout, its configuration in the Solaris RH200 Deluxe

Heater limits it to volatile lockout, i.e. the restart from this

condition is possible by the interruption and subsequent

restoration of the mains power supply.

Features:

• Compliance with AGA standard for automatic gas

burner flame monitoring and control systems

• Compliance with EN 298 (European standard for

automatic gas burner flame monitoring and control

systems)

• Compliance with AGA (Australian standard for

automatic gas burner flame monitoring and control

systems)

• Flame monitoring based on rectification property of

the flame (ionisation)

TECHNICAL DATA

Supply voltage 220~240V AC 50Hz

Operating temperature -20°C +60°C

Ambient humidity 90%max at 40°C

Protection degree IPX4

Timings:

Self Check time 1.5 s

Safety time (TS) 25 s

Drop out time on running flame failure 1 s

Power consumption, at start up 10VA

Power Consumption, Running 4VA

Ignition

Ignition Voltage 15kV with 40pF load

Spark repetition rate 33 Hz

Max. Cable length 1M

Recommended spark gap 0.14”

Consumption 2,5 VA

Spark energy 3 uAs

Loading ...

Loading ...

Loading ...