Loading ...

Types 912H, N, Y200H, N, and R922N

2

912H 1/4 1/4 or 3/8 High Pressure Drilled and Screened 350 000

Y200H 1/4 3/8 High Pressure Slot 350 000

912N 1/4 1/4 or 3/8 High or Low Pressure Drilled and Screened 350 000

Y200N 1/4 3/8 High or Low Pressure Slot 350 000

R922N 1/4. 1/2, or FEMALE POL 1/2 High or Low Pressure 3/4-inch FNPT and Screened 725 000

Make sure gas ow through the regulator is in the same

direction as the arrow on the body— ”Inlet” and “Outlet”

connections are clearly marked. The installation

should be adequately protected from vehicular trafc

and damage from other external sources. Install the

regulator so that any gas discharge through the vent or

vent assembly is over 3-feet (0,91 m) horizontally from

any building opening below the level of the discharge.

Install the regulator high enough above ground

level—at least 18-inches (457 mm) so that rain splatter

cannot freeze in the vent. Whether a protective hood

is used or not, do not install the regulator in a location

where there can be excessive water accumulation or

ice formation, such as directly beneath a downspout,

gutter, or roof line of a building.

Before installing the regulator, check for damage which

might have occurred in shipment. Also check for and

remove any dirt or foreign matter which may have

accumulated in the regulator body or pipeline. Apply

pipe compound to the male threads of the pipe.

A hood or encasement should be used to protect the

Type Y200H or Y200N vent opening from the elements.

The regulator vent opening should slope down

sufciently to allow any condensate to drain that may

have collected in the spring case. Be careful that the slot

in the hood for the regulator outlet piping does not extend

too far and expose the vent to the elements.

The Types 912H, 912N, and R922N can be installed

outdoors without a protective hood if their vent is

pointed verticaIly down.

Horizontally mounted regulators, such as found on

single cylinder or tank installations, must be installed

beneath a protective cover. If possible, slope or turn

the vent down sufciently to allow any condensation to

drain out of the spring case. Be careful that the slot in

the hood or cover for the regulator’s outlet piping does

not extend too far and expose the vent to the elements.

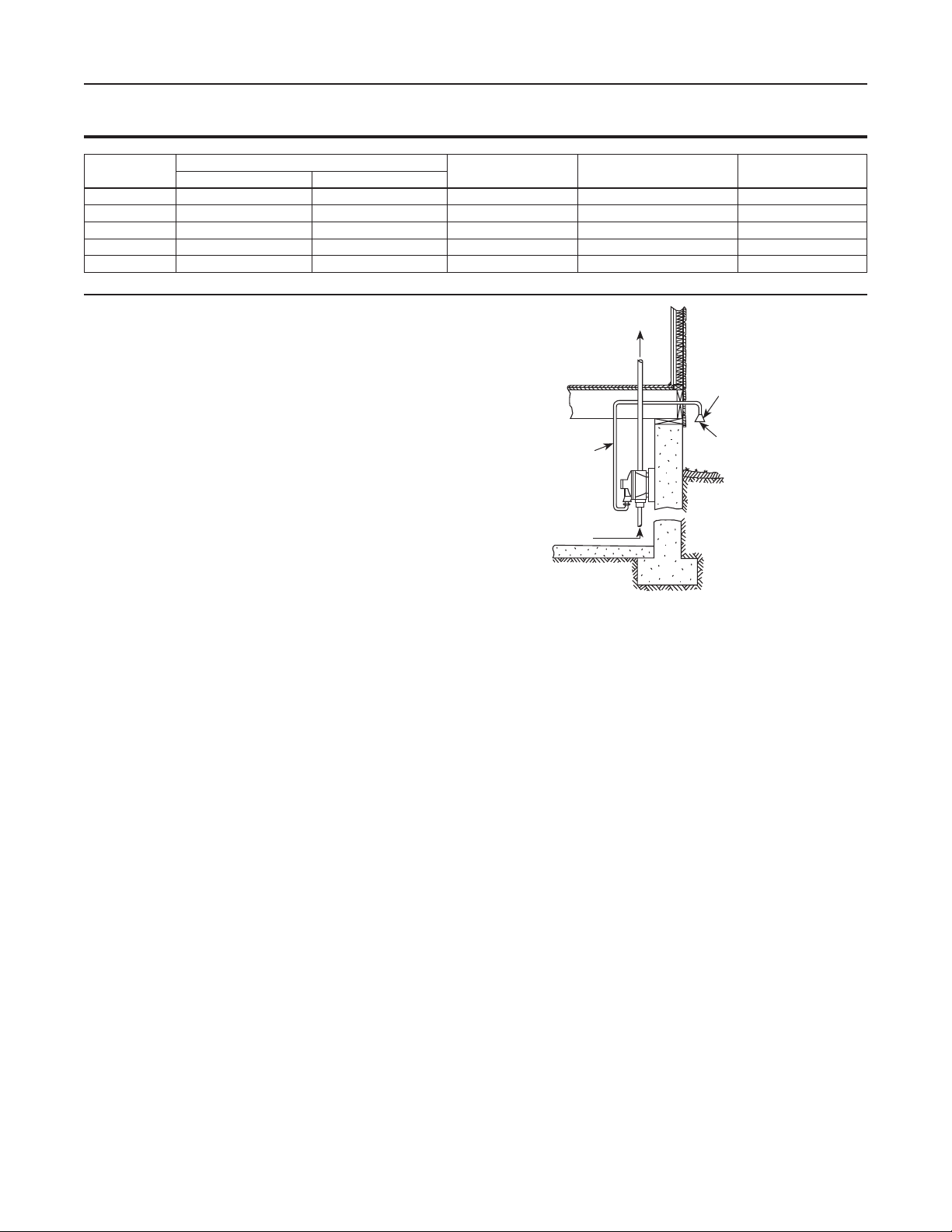

Regulators installed indoors are limited to 20 psig

(1,4 bar) maximum inlet pressure. Types Y200H,

Y200N, and most 912s must not be used on indoor

installations because a vent line to the outside of the

building cannot be installed. On regulators that have

a tapped vent (Type R922N and some 912s), use pipe

or tubing equal in size to the regulator’s vent for the

vent line.

To install the vent line, remove the vent screen and

apply a good grade of pipe dope to the male threads of

the line, see Figure 2. Vent piping or tubing must not

restrict the ow passage of the regulator’s internal relief

valve. A vent assembly, such as Fisher

®

Type Y602,

should be used on the end of the vent line. The same

Figure 2. Typical Indoor Installation with

Vent Line and Vent Assembly

Loading ...

Loading ...