Loading ...

Loading ...

Loading ...

Installation

Installation Steps

Installation

Installation Steps

Dryer

Wall

Duct

exhaust

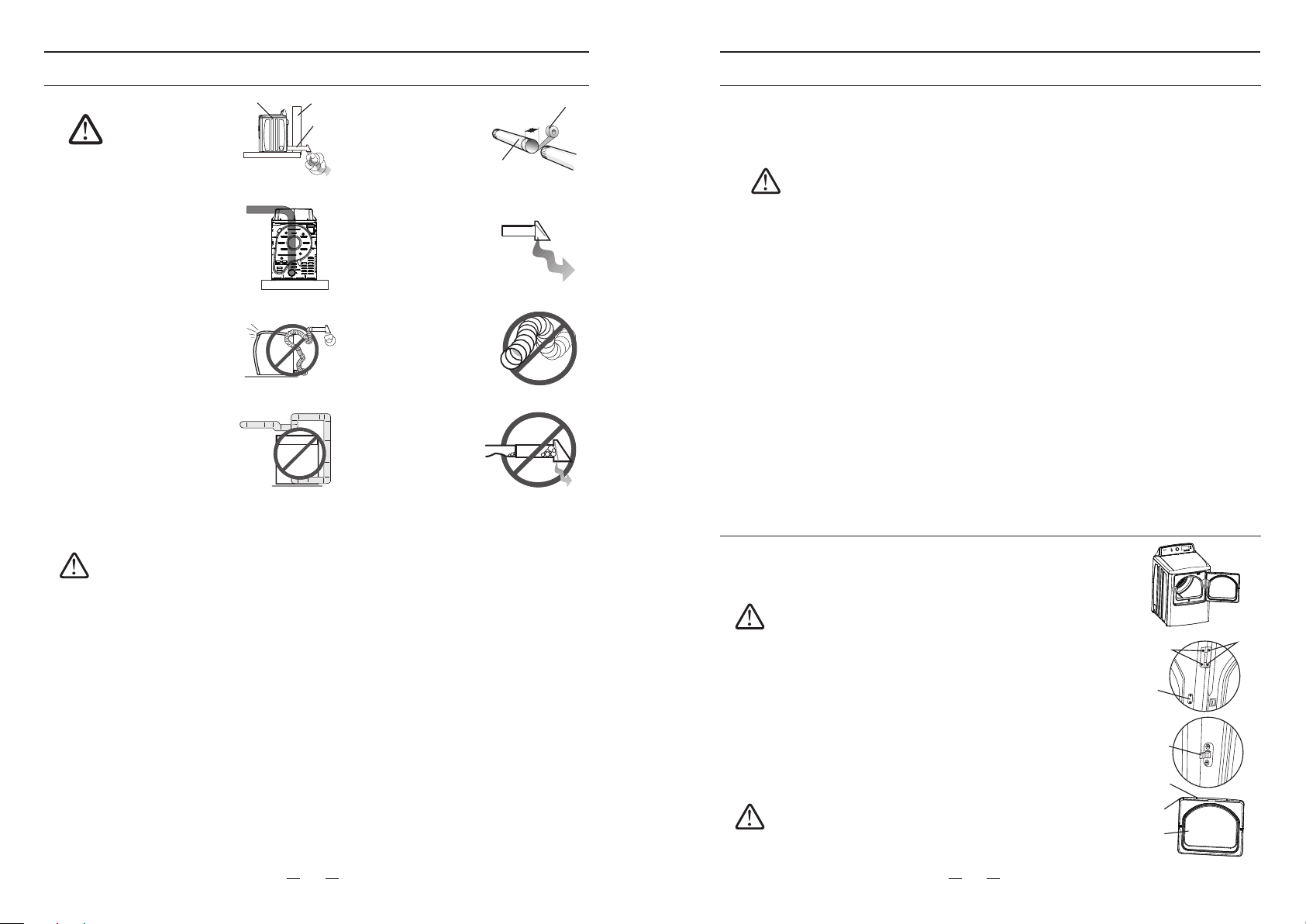

Make sure your

dryer is installed

properly so it

exhausts air

easily.

4"

Duct

Tape

Use a 4 inch. (10.2cm)

diameter rigid metal

duct. Tape all joints,

including at the dryer.

Never use lint-trapping

screws.

Keep ducts as

straight as

possible.

Clean all old ducts

before installing your

new dryer. Be sure the

vent flap opens and

closes freely. Inspect

and clean the exhaust

system annually.

WARNING

DO NOT

restrict your

dryer with a poor

exhaust system.

DO NOT use a plastic,

thin foil, or non-metal

flexible duct.

DO NOT

use

unnecessarily

long ducts that

have many

elbows.

DO NOT use

dented or clogged

ducts and vent.

5. Review the “Electric requirements” section on page 11.

BEFORE OPERATING OR TESTING, follow the grounding instructions in the

“Grounding” section on page 13.

U.S. Models:

Risk Of Electric Shock - All U.S. models are produced for a 3-WIRE SYSTEM

CONNECTION.

The dryer frame is grounded to the neutral conductor at the terminal block.

A 4-WIRE SYSTEM CONNECTION is required for new or remodeled construction,

mobile homes, or if local codes do not permit grounding through neutral conductor.

If the 4-wire system is used, the dryer frame cannot be grounded to the neutral

conductor at the terminal block. Refer to the “Electric requirements” section on

page 11 for 3-WIRE or 4-WIRE SYSTEM CONNECTIONS.

WARNING

Remove the terminal block cover plate.

Insert the power cord with a UL-listed strain relief through the hose provided in the

cabinet near the terminal block.

- A strain relief must be used.

Do not loosen the nuts already installed on the terminal block. Be sure they are tight.

Use a 3/8" (1cm) deep well socket.

6. [GAS MODELS ONLY]

Review the “Gas requirements” section on page 11. Remove the pipe thread

protective cap. Apply a pipe joint compound or about 1 ½” wraps of teflon tape over all

threaded connections.

- The pipe joint compound must be resistant to the actions of any liquefied petroleum

gas.

Connect the gas supply to your dryer. An additional fitting is required to connect the

3/4" (1.9cm) female thread end of a flexible connector to the 3/8" (1cm) male threaded

end on the dryer.

Securely tighten the gas line fitting over the threads.

Turn on the gas supply.

Check all gas connections for leaks using a soap solution.

If bubbles appear, tighten the connections and recheck. DO NOT use an open

flame to check for gas leaks.

WARNING

Your dryer is built to open from left to right. You can reverse

the direction (right to left) by following steps.

1. Unplug the power cord.

2. Remove the four screws connecting the body and hinges.

Door Reversal

7. Using a level, check your dryer and make the necessary adjustments to the leveling

legs.

8. Make sure all gas connections (Gas Models only), exhaust and electrical connections

are complete. Plug in your dryer.

9. [GAS MODELS ONLY]

The burner may not ignite initially due to air in the gas line. Allowing your dryer to

operate on a heat setting will purge the line. If the gas does not ignite within 5 minutes,

turn your dryer off and wait 5 minutes. Be sure the gas supply to your dryer has been

turned on. In order to confirm the gas ignition, check the exhaust for heat.

10. Final Installation Check

- Make sure the dryer is plugged into an electrical outlet and is properly grounded.

- The exhaust ductwork is hooked up and the joints are taped.

- A plastic flexible duct in NOT used.

- Use rigid or stiff-walled flexible metal vent material.

- The dryer is leveled and is sitting firmly on the floor.

- Gas models - the gas is turned on with no gas leakage.

- Start your dryer to confirm that it runs, heats, and shuts off.

Take care the door when removing and installing the

screws in case it drops and hurts you.

CAUTION

Screws for

hinge and

body

Screws for

hinge and

door

Locker

cover

3. Put the door aside. Remove the screws for locker cover on the

right body and screws for the locker on the left body.

4. Install the locker onto the right body with screws. Install the

locker cover onto the left body.

5. Remove all screws around the door.

6. Disassemble the inside door board from the outside door board.

o

7. Turn the inside door board 180 then install it with the outside

door board.

8. Fix the screws back onto the door sides except the hinges.

9. Install the hinges onto the body left with screws.

10. Install the door onto the unit body with handles right.

Locker

Screw

Outside

door

board

Inside

door

board

Take care the hinges and screws for door and body.

There are two different screws. Screws with flat head

are for hinges and door.

CAUTION

15

16

Loading ...

Loading ...

Loading ...