64 and 67C Series Regulators

D450128T012

Instruction Manual

Form MCK-2133

January 2010

www.sherregulators.com/lp

!

WARNING

Failure to follow these instructions or to properly

install and maintain this equipment could result in

an explosion and/or re causing property damage

and personal injury or death.

Fisher

®

equipment must be installed, operated,

and maintained in accordance with federal,

state, and local codes and Emerson Process

Management Regulator Technologies, Inc.

instructions. The installation in most states must

also comply with NFPA No. 54 and 58 standards.

Only personnel trained in the proper procedures,

codes, standards, and regulations of the

LP-Gas industry should install and service

this equipment.

THINGS TO TELL THE GAS CUSTOMER:

1. Point out the regulator’s vent to the customer (or vent

assembly or vent tube), and stress that this opening must

remain unobstructed at all times. Tell the customer to be

sure to check the vent opening after a freezing rain, sleet

storm, or snow to make sure ice has not formed in the vent.

2. Show the customer the shutoff valve on the container. The

customer should close this valve immediately if gas is

smelled, appliance pilot lights fail to stay on or appear higher

than usual, or any other abnormal situation occurs.

3. Tell the customer to call your company to service the

regulator if the regulator vents gas or a leak develops in the

system. Only a qualied gas service person should

install or service the regulator.

Introduction

Scope of the Manual

This manual provides instructions and maintenance for the

following high-pressure regulators: Types 64, 64KB, 64SR,

67CW, 67CH, 67CD, and 67CN regulators.

Description

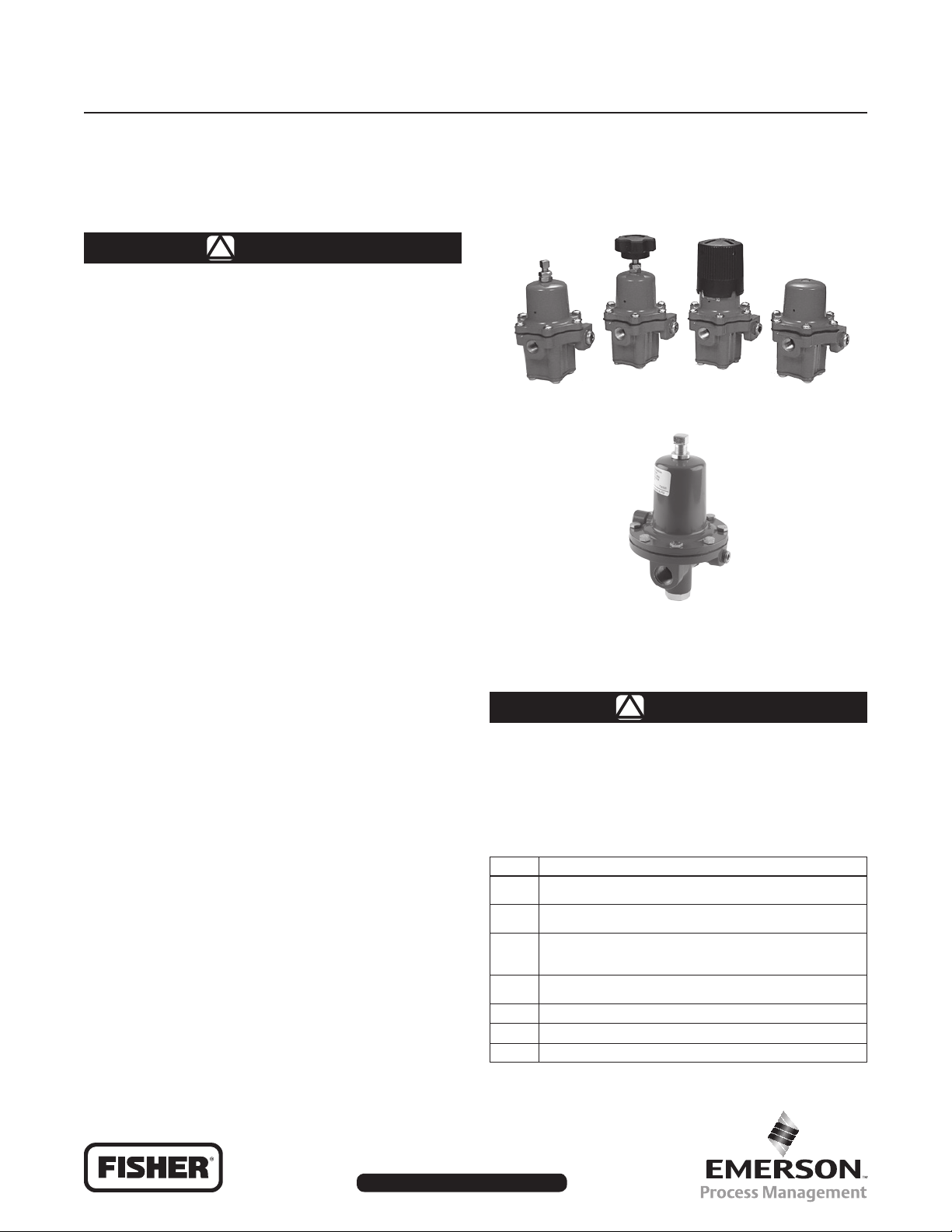

The 64 and 67C Series direct-operated regulators (Figure 1) are

designed for high-pressure (pounds per square inch) service and can

be used on either vapor applications in LP-Gas, Natural Gas, and Air

or liquid LP-Gas applications. Depending upon type, outlet pressure

ranges from 3 to 135 psig (0,21 to 9,3 bar). Type 64SR can be used

as a First Stage LP-Gas regulator–reducing tank pressure to

10 psig (0,69 bar) for a Second Stage regulator. Type 64KB is the

only regulator in this series suitable for anhydrous ammonia (NH

3

)

service. The regulators are normally painted red.

64 and 67C Series Regulators Instruction Manual

67C SERIES REGULATORS

W8810

64 SERIES REGULATOR

Figure 1. 64 and 67C Series Regulators

P1027

Table 1. Available Congurations

CAUTION

Do not use the 67C, 64, or 64SR Series regulators

in anhydrous ammonia (NH

3

) service. They

contain brass materials that are not compatible

with anhydrous ammonia (NH

3

).

TYPE DESCRIPTION

64

Basic regulator with four spring ranges from 3 to 100 psig

(0,21 to 6,9 bar).

64SR

Internal relief version with three spring ranges from 3 to 35 psig

(0,21 to 2,4 bar).

64KB

For use with anhydrous ammonia (NH

3

) with handwheel

adjustment and ve spring ranges from 3 to 100 psig

(0,21 to 6,9 bar). Includes a special diaphragm protector.

67CW

Basic regulator with wrench adjustment and four spring ranges

from 3 to 135 psig (0,21 to 9,3 bar); no relief.

67CH Basic regulator with handwheel adjustment.

67CD Basic regulator with dial cap adjustment.

67CN Basic regulator, factory set with no eld adjustment.

Loading ...

Loading ...

Loading ...