Loading ...

Loading ...

Loading ...

20 31-5000500 Rev. 0

ENGLISH

TEST RUN AND FAULT CODE

Before Test Run

• Apply power to system to energize the crankcase or sump of the compressor. Power on system at least 12 hours before

operation to protect the compressor.

Check the connections at the drainpipe and wire connection lines to make sure they are correct.

• The drain outlet should be placed lower than the drain outlet of the unit. Insulate the condensate drain lines to prevent

condensation forming on the pipe. The drain line should slope away from the indoor unit.

Checkup of Installation

• Check if the main voltage is matching

• Check for any leaks at the piping joints

• Check main electrical connections for indoor and outdoor units

• Check if the serial numbers of the terminals are matched properly

• Check to make sure the structure can properly accommodate the indoor units

• Check for excessive noise

• Check insulation on refrigerant and condensate drain lines

• Check condensate drains for free flow

• Check final position of indoor units

Test Run

• The installation technician should complete a run test and evaluation. Compare the testing procedures according to the

manual and check if the temperature control works properly.

• The following procedure can be used to force the system into running mode if the system fails to start. The function is

not available for the type with remote control.

• Set the YR-E17 wired controller to cooling/heating mode, press "ON/OFF" button for 10 seconds to enter into the

compulsive cooling/heating mode. Press "ON/OFF" button again to quit the compulsive running and stop the operation

of the system.

Fault Remedies

When any fault appears, refer to “Inquiry of fault records of indoor units” at the previous page and consult the fault code

of line control or the number of LED flashes on the control panel. Refer to the below table lookup fault descriptions.

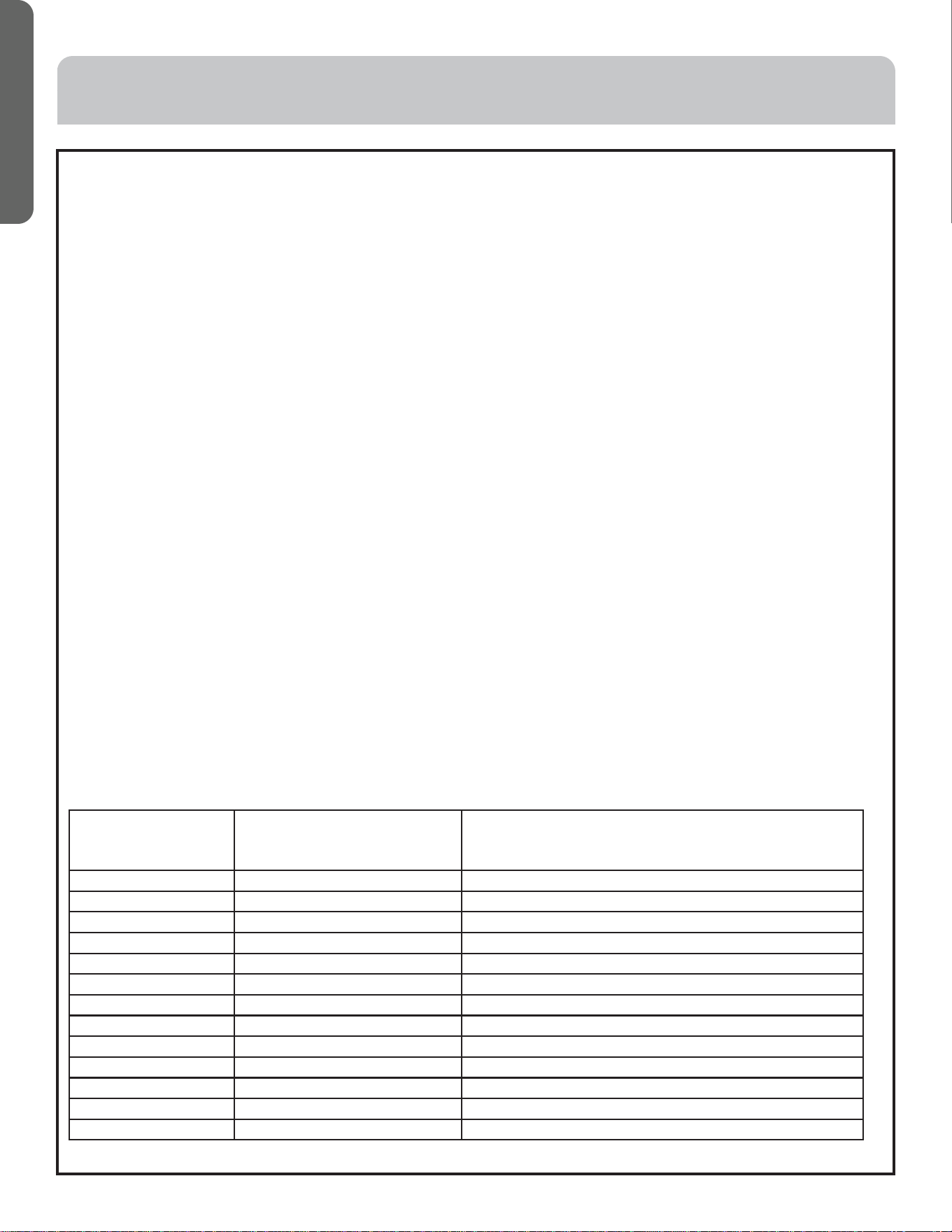

Indoor Unit Faults

Failure Code at Wired

Controller

PCB LED5 (indoor Units) /

Receiver Timer Lamp (Remote

Controller)

Fault Descriptions

01 1 Fault of indoor unit ambient temp. sensor TA

02 2 Fault of indoor unit pipe temp. sensor TC1

03 3 Fault of indoor unit pipe temp. sensor TC2

04 4 Fault of indoor unit dual heat source temp. sensor

05 5 Fault of indoor unit EEPROM

06 6 Fault of communication between indoor & outdoor units

07 7 Fault of communication between indoor unit and wired control

08 8 Fault of indoor unit float switch

09 9 Fault of duplicate indoor unit address

12 12 Fault of indoor unit 50Hz Zero-crossing

14 14 Fault of indoor unit DC motor

18 18 BS valve box or 4WV switch failure

20 20 Corresponding faults of outdoor units

Loading ...

Loading ...

Loading ...