Documents: Go to download!

User Manual

- User Manual - (English, French)

- Spec Sheet - (English)

- Warranty - (English)

- Part List - (English)

- TOOLS & PARTS

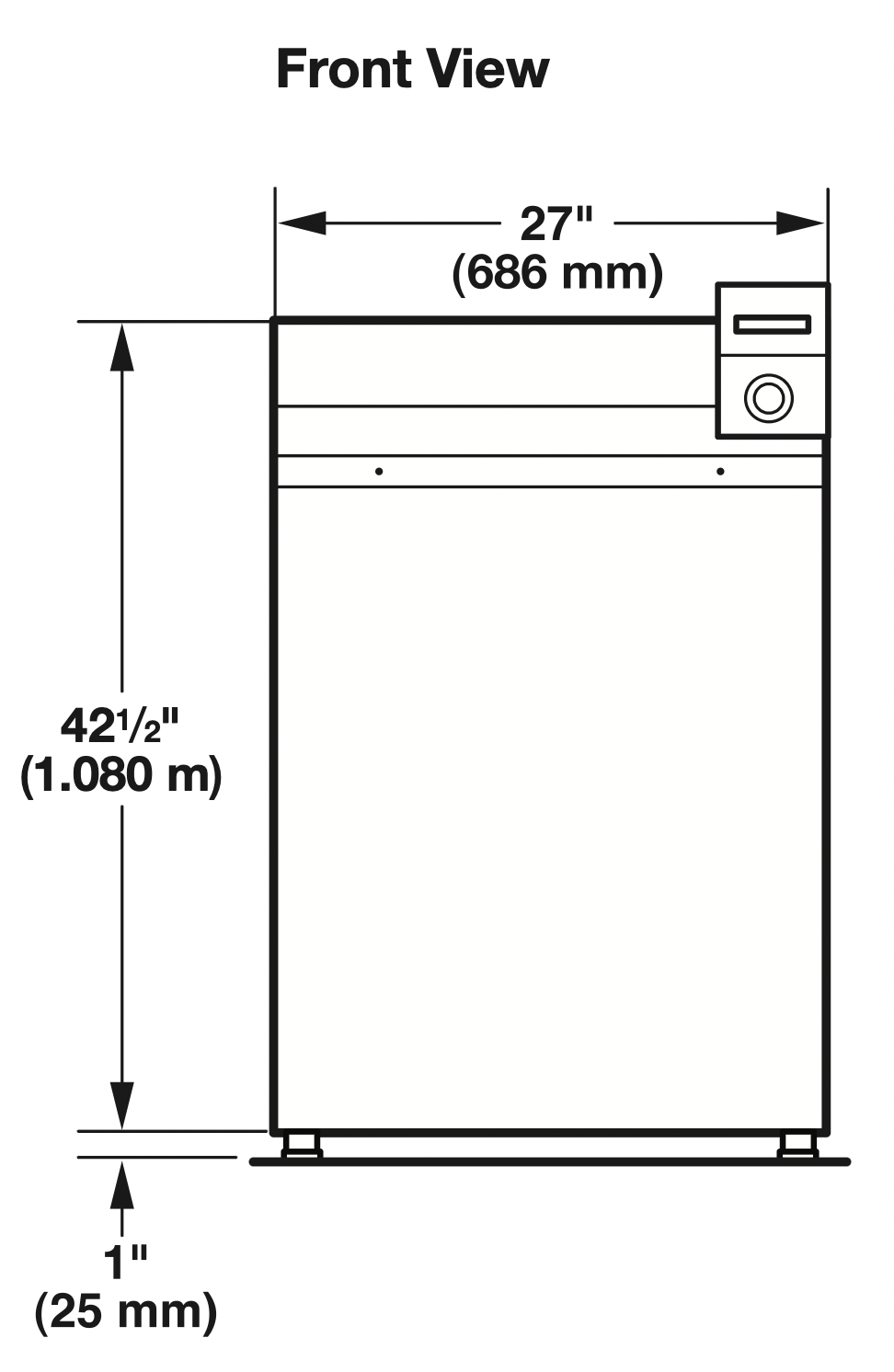

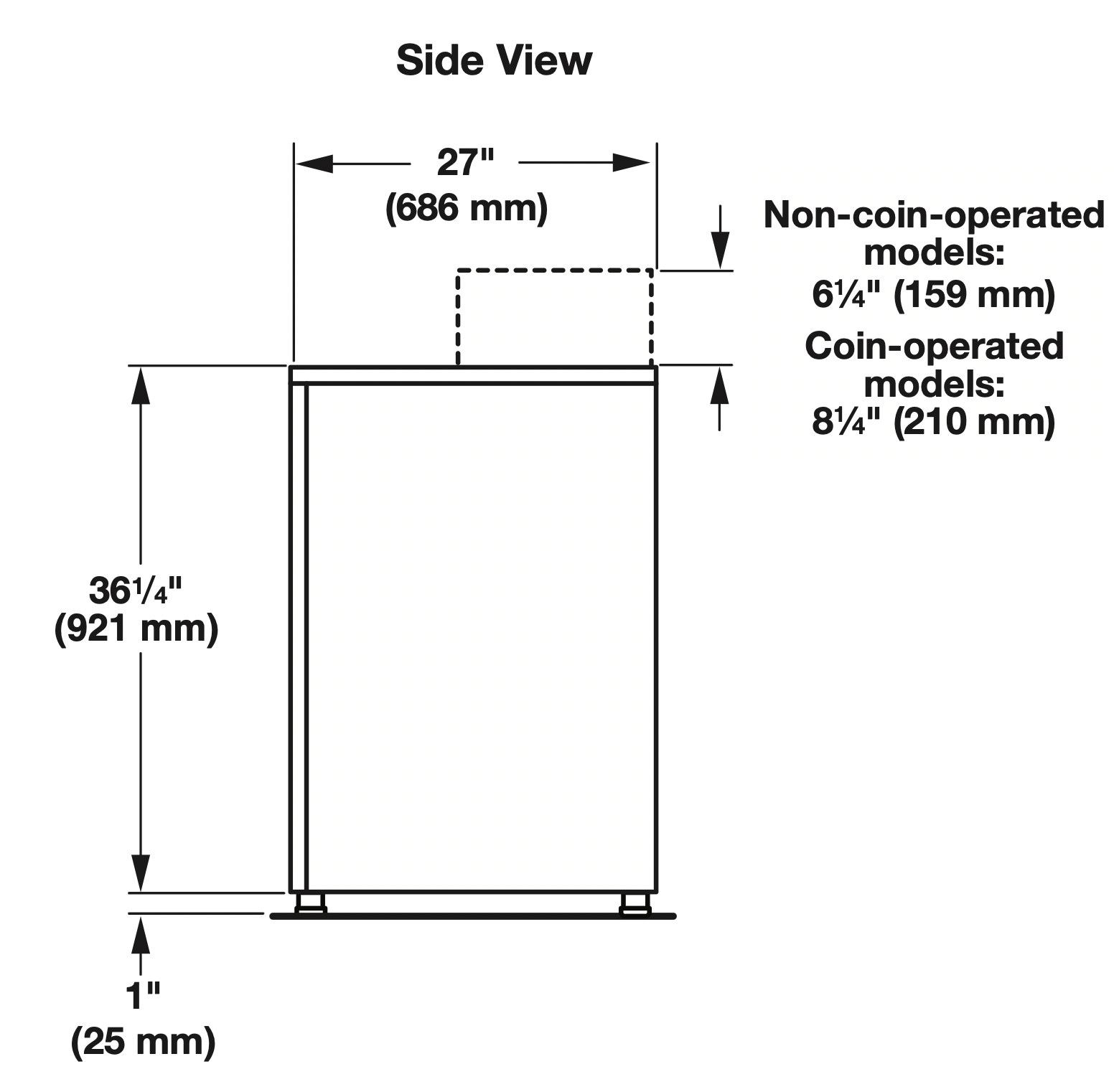

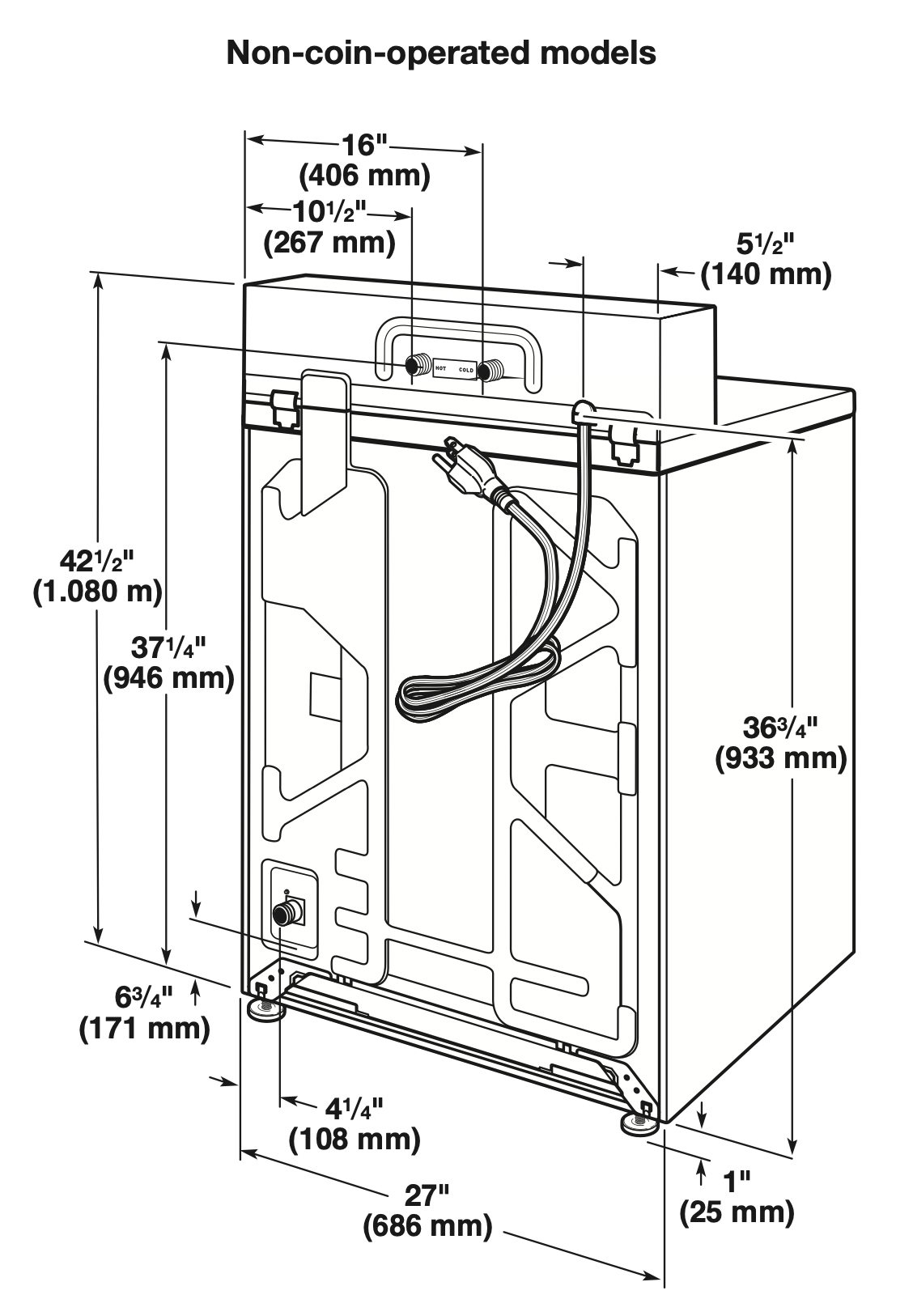

- DIMENSIONS

- LOCATION REQUIREMENTS

- INSTALLATION INSTRUCTIONS

- LEVEL WASHER

- CONNECT DRAIN HOSE

- DRAIN SYSTEM

- CONNECT INLET HOSES

- COMPLETE INSTALLATION

- INSTALLING COIN SLIDE AND COIN BOX

- WASHER MAINTENANCE

Table of contents

Owner Manual Commercial Washer

TOOLS & PARTS

Tools Needed:

Level

Pliers

Utility Knife

9/16" (14 mm) Open-End Wrench

Flat-Blade Screwdriver

Optional tools:

See other models: MAT20CSAWW MAT20PDAWW MLG22PDAWW MGD6200KW MZC3122FW

Flashlight

Bucket

Parts Supplied:

Water Inlet Hoses (2)

Inlet Hose Washers (4)

Drain Hose with Clamp, U-Form, and Cable Tie

DIMENSIONS

LOCATION REQUIREMENTS

Selecting the proper location for your washer improves performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room, or recessed area. See “Drain System.”

Companion appliance location requirements should also be considered.

IMPORTANT: Do not install or store the washer where it will be exposed to the weather. Do not store or operate the washer in temperatures at or below 32°F (0°C). Some water can remain in the washer and can cause damage in low temperatures. Proper installation is your responsibility.

You will need:

- A water heater set to 120°F (49°C).

- A grounded electrical outlet located within 4 ft. (1.2 m) of power cord on back of washer. See “Electrical Requirements.”

- Hot and cold water faucets located within 4 ft. (1.2 m) of hot and cold water fill valves on washer, and water pressure of 20–100 psi (138–690 kPa). A pressure reduction valve should be used in the supply line where inlet pressure entering the building exceeds 100 PSI (690 kPa) to avoid damage to the washer mixing valve.

- Single washer installations require 12" (300 mm) minimum risers to provide an air cushion and avoid noise and damage to valves.

- A level floor with maximum slope of 1" (25 mm) under entire washer. Installing on carpet is not recommended.

- Floor must support washer’s total weight (with water and load) of 315 lbs (143 kgs).

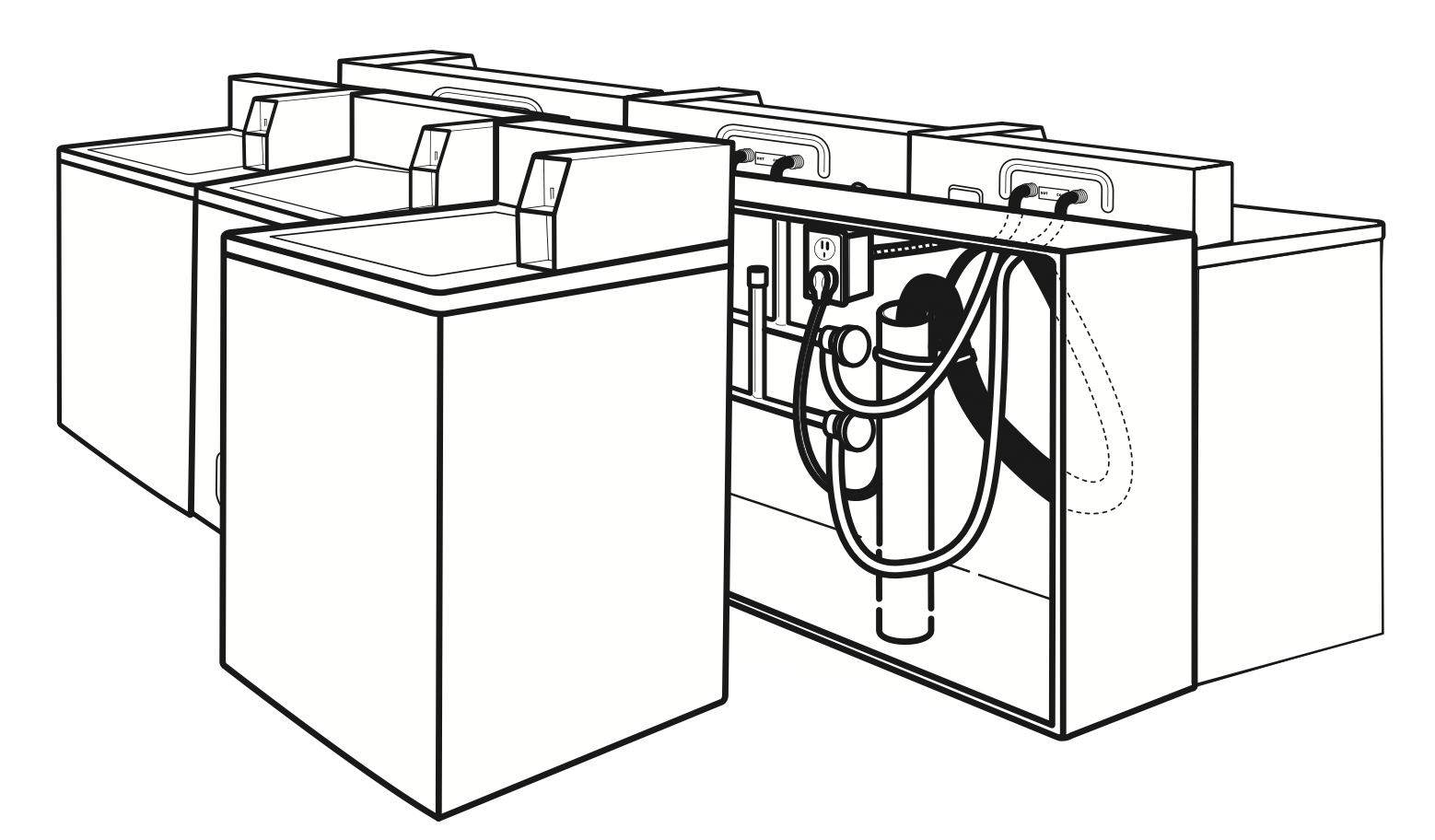

- A floor drain under the bulkhead. Prefabricated bulkheads with electrical outlets, water inlet lines, and drain facilities should be used only where local codes permit.

Recessed Area or Closet Installation

This washer may be installed in a recessed area or closet. The installation dimensions shown are the minimum spaces allowable. Additional spacing should be considered for ease of installation and servicing. If closet door is installed, the minimum air openings in top and bottom of door are required. Louvered doors with air openings in top and bottom are acceptable. Companion appliance spacing should be considered.

Minimum installation spacing

INSTALLATION INSTRUCTIONS

WARNING - Excessive Weight Hazard

- Use two or more people to move and install washer.

- Failure to do so can result in back or other injury.

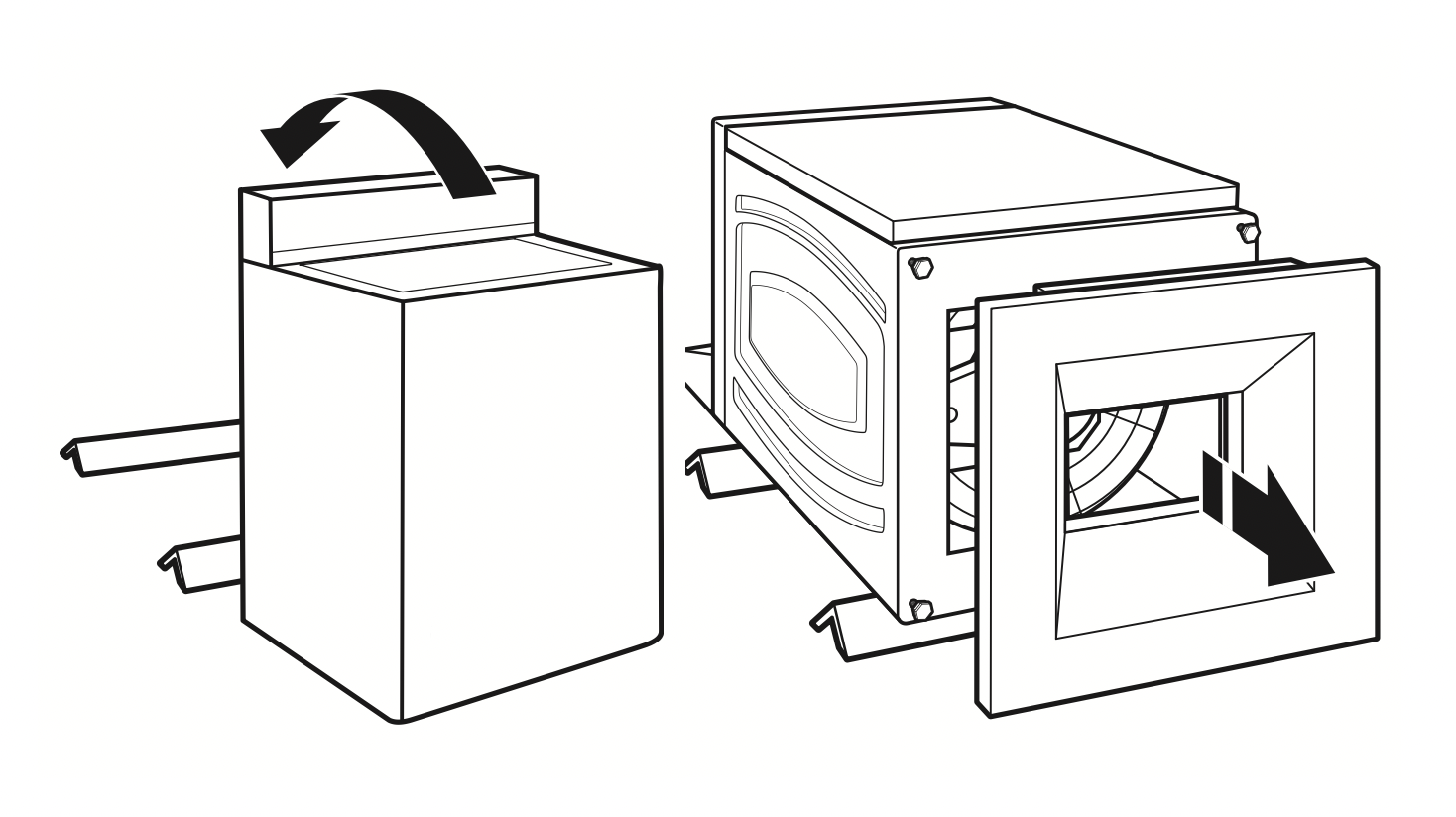

It is necessary to remove all shipping materials for proper operation and to avoid excessive noise from washer.

- Move washer to within 4 ft (1.2 m) of its final location; it must be in a fully upright position.

NOTE: To avoid floor damage, set washer onto cardboard before moving it and make sure lid is taped shut.

- To avoid damaging floor, place cardboard supports from shipping carton on floor behind washer. Tip washer back and place on cardboard supports. Remove shipping base. Set washer upright.

IMPORTANT: Removing shipping base is necessary for proper operation.

NOTE: Keep shipping base in case you need to move washer later.

- Remove tape from washer lid, open lid, and remove cardboard packing tray from tub. Be sure to remove all parts from tray.

NOTE: Keep tray in case you need to move washer later.

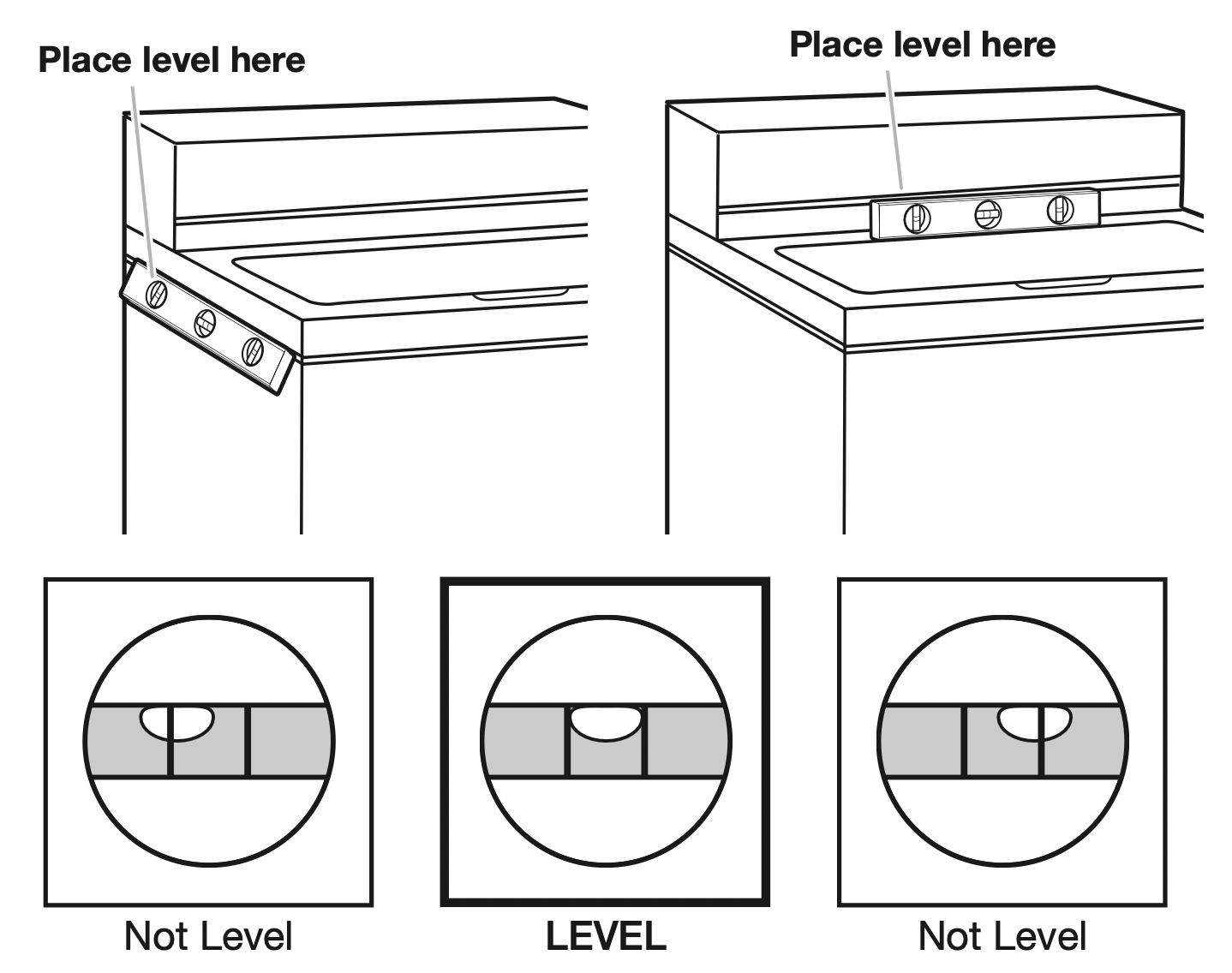

LEVEL WASHER

IMPORTANT: Level washer properly to reduce excess noise and vibration.

WARNING - Excessive Weight Hazard

- Use two or more people to move and install washer.

- Failure to do so can result in back or other injury.

- Move the washer to its final location. Place a level on top edges of washer. Use side seam as a guide to check levelness of sides. Check levelness of front using lid, as shown. Rock washer back and forth to make sure all four feet make solid contact with floor.

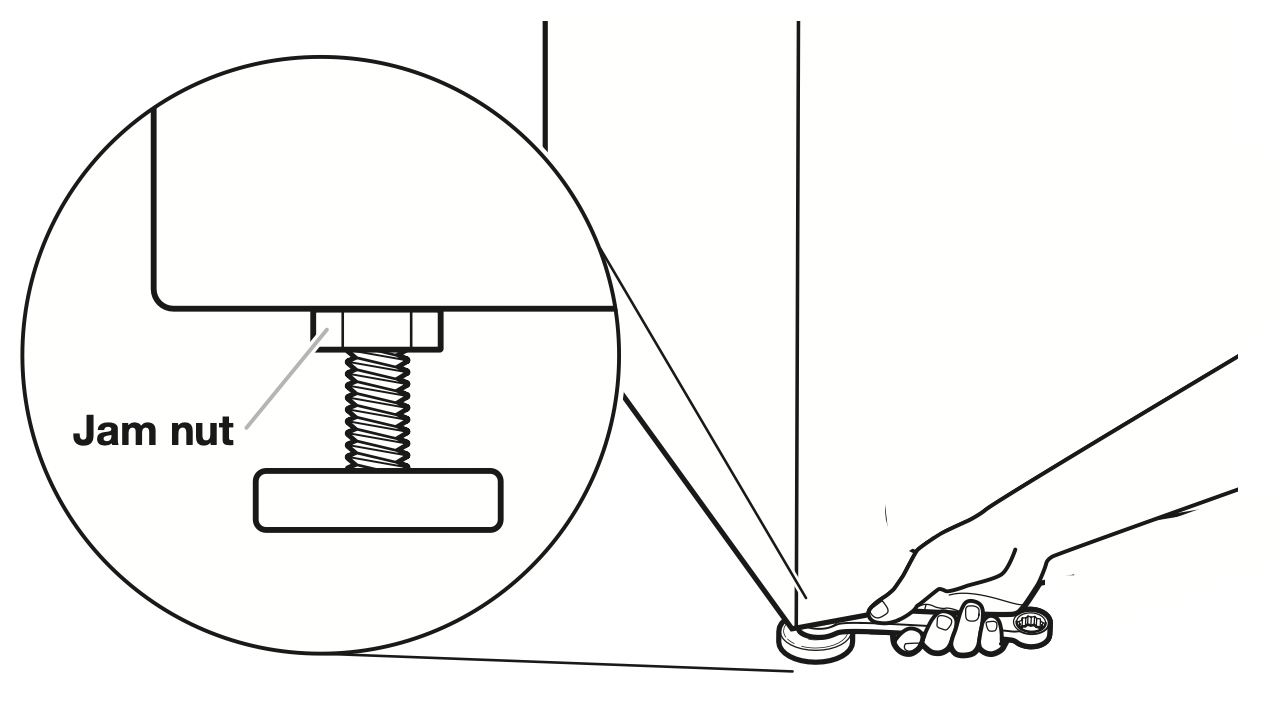

- Use a 9/16" or 14 mm open-end or adjustable wrench to turn jam nuts clockwise on feet until they are about 1/2" (13 mm) from the washer cabinet. Then turn the leveling foot clockwise to lower the washer or counterclockwise to raise the washer. Recheck levelness of washer and repeat as needed.

HELPFUL TIP: You may want to prop up front of washer about 4" (102 mm) with a wood block or similar object that will support weight of washer.

- When washer is level, use a 9/16" or 14 mm open-end or adjustable wrench to turn jam nuts counterclockwise on leveling feet tightly against washer cabinet.

CONNECT DRAIN HOSE

Proper routing of the drain hose avoids damage to your floor due to water leakage.

Remove drain hose from the washer basket

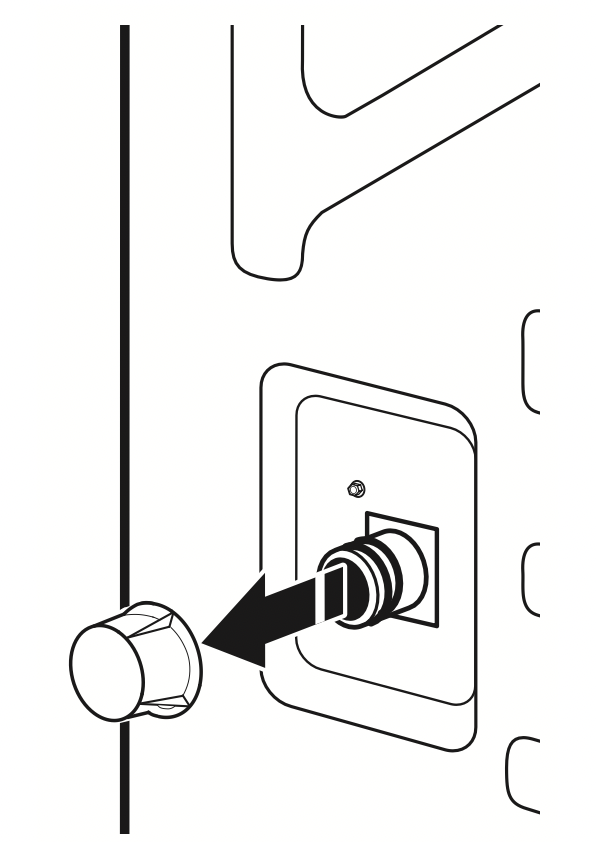

- Remove cap from the washer drain port on the back of the washer.

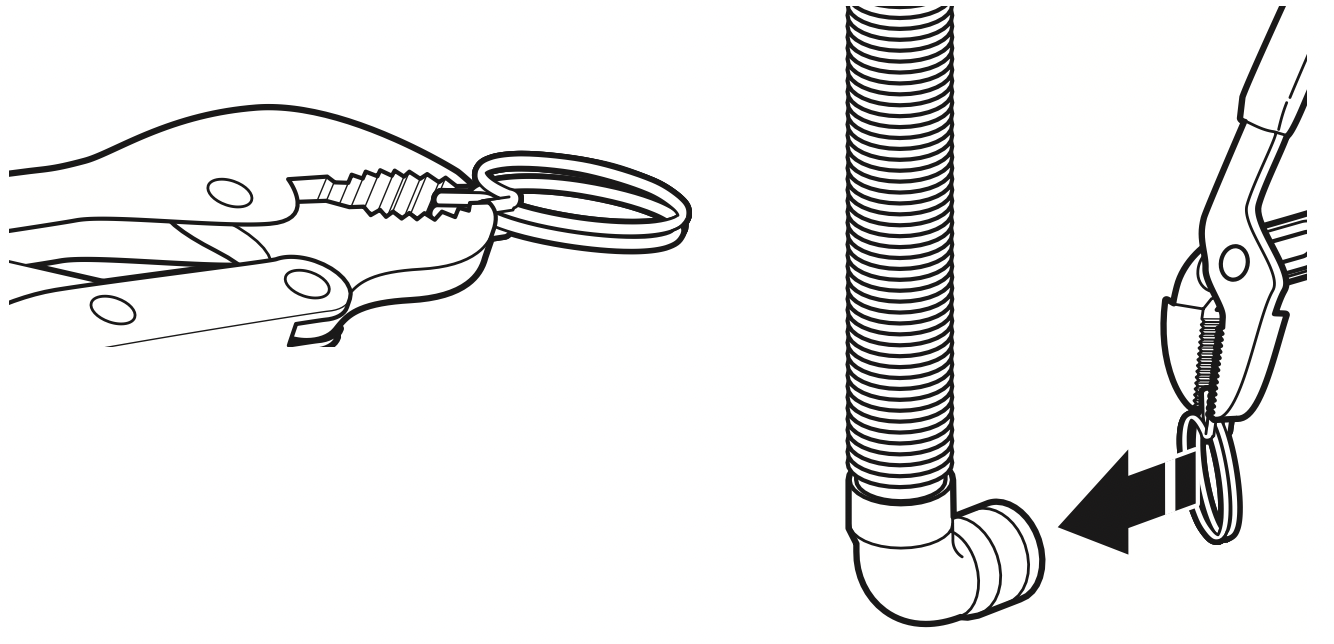

- If clamp is not already in place on elbow end of drain hose, slide it over end as shown.

- Squeeze clamp with pliers and slide elbow end of drain hose onto washer drain port and secure with clamp.

- The washer drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub.

- Place hose into standpipe (shown in picture) or over side of laundry tub.

IMPORTANT:

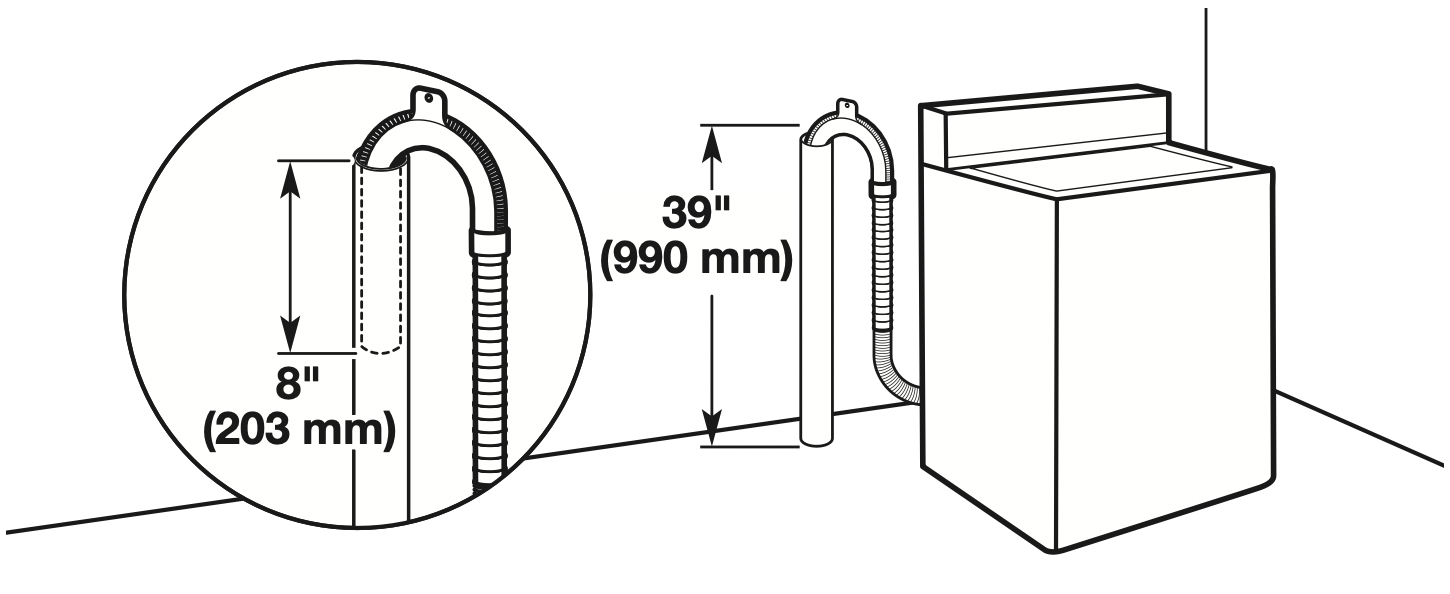

Drain hose is not to exceed 8" (203 mm) into drain pipe; do not force excess hose into standpipe or lay on bottom of laundry tub. Drain hose form must be used.

It is the responsibility of the installer to install and secure the drain hose into the provided plumbing/drain in a manner that will avoid the drain hose coming out of, or leaking from, the plumbing/drain.

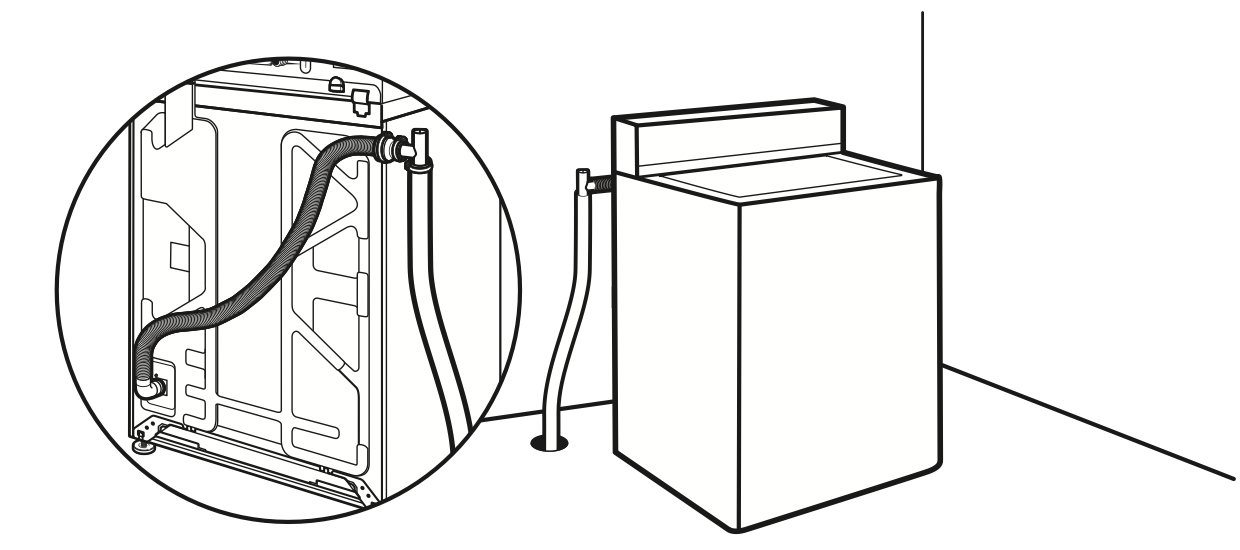

- For floor drain installations, you will need to remove the drain hose form from the end of the drain hose. You may need additional parts with separate directions. See “Tools and Parts.”

- The floor drain system requires a siphon break that may be purchased separately. The siphon break (Part Number 285320) must be a minimum of 28" (710 mm) from the bottom of the washer. Additional hoses might be needed.

DRAIN SYSTEM

Drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum carry-away capacity: 10 gal. (38 L) per minute. Top of standpipe must be at least 39" (990 mm) high; install no higher than 96" (2.44 m) from bottom of washer.

Wall standpipe drain system

See requirements for floor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number 285320). Minimum siphon break: 28" (710 mm) from bottom of washer. Additional hoses may be needed.

Laundry tub drain system

Minimum capacity: 20 gal. (76 L). The top of the laundry tub must be at least 39" (990 mm) above floor.

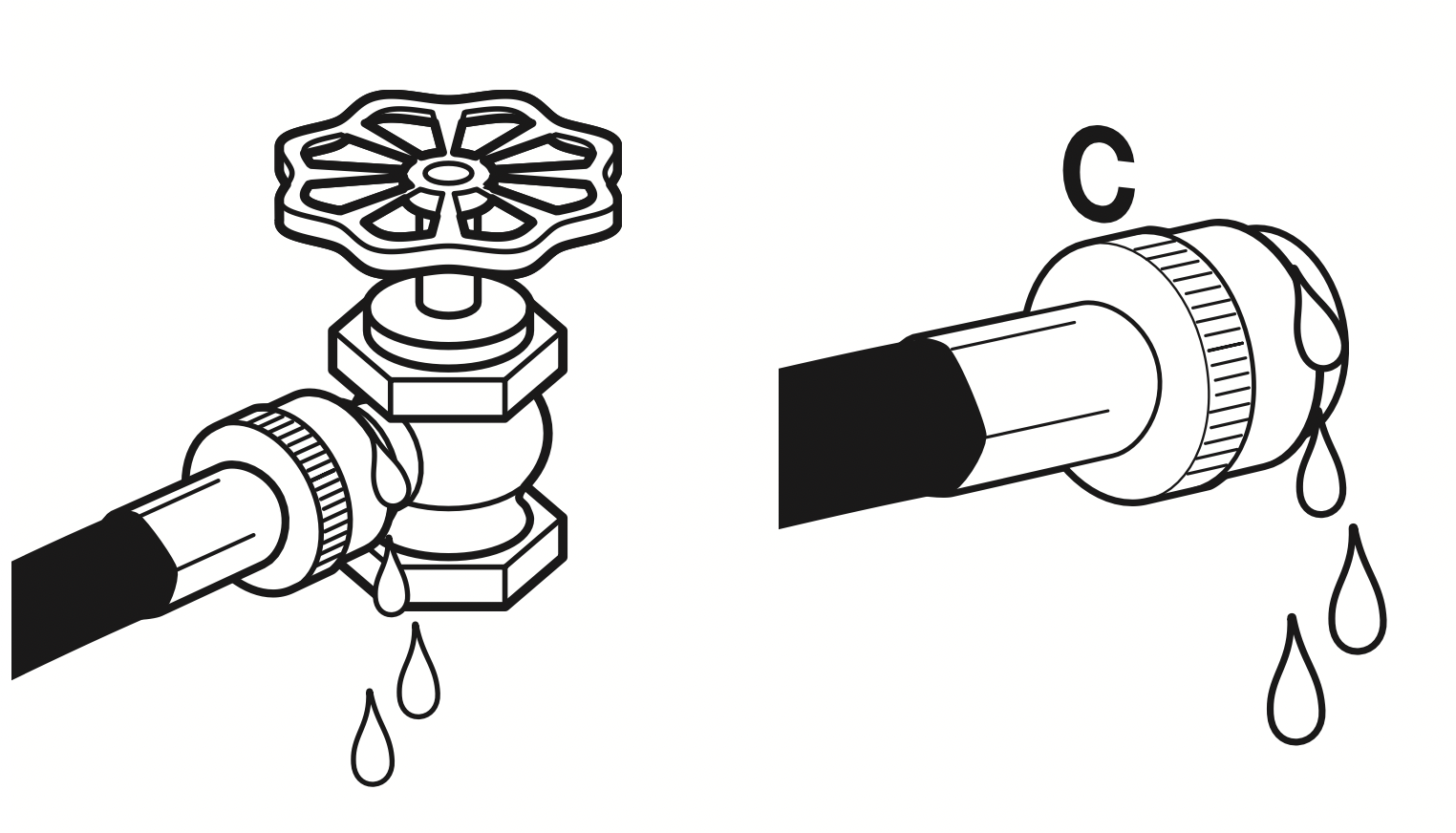

CONNECT INLET HOSES

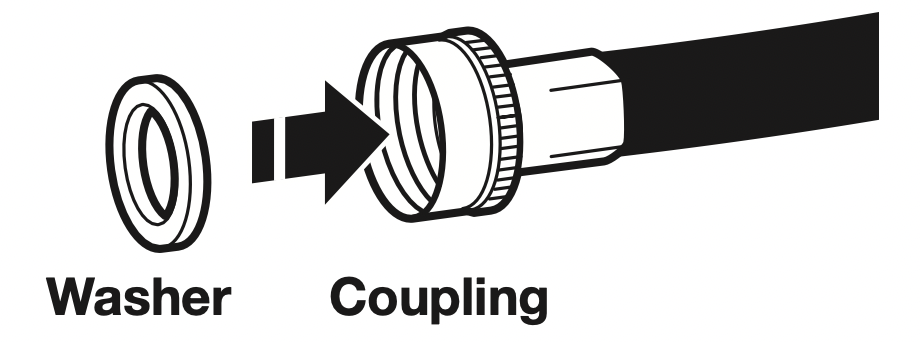

Insert new hose washers (supplied) into each end of the inlet hoses. Firmly seat the washers in the couplings.

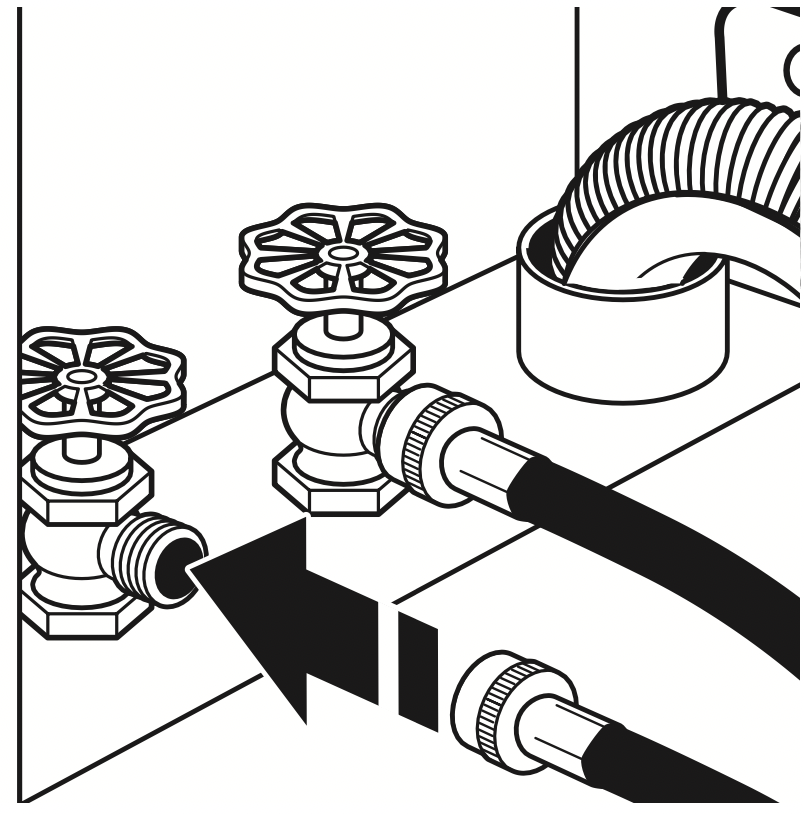

Connect Inlet Hoses to Water Faucets

- Attach hose to hot water faucet. Screw on coupling until it is seated on washer. Repeat process for cold

water.

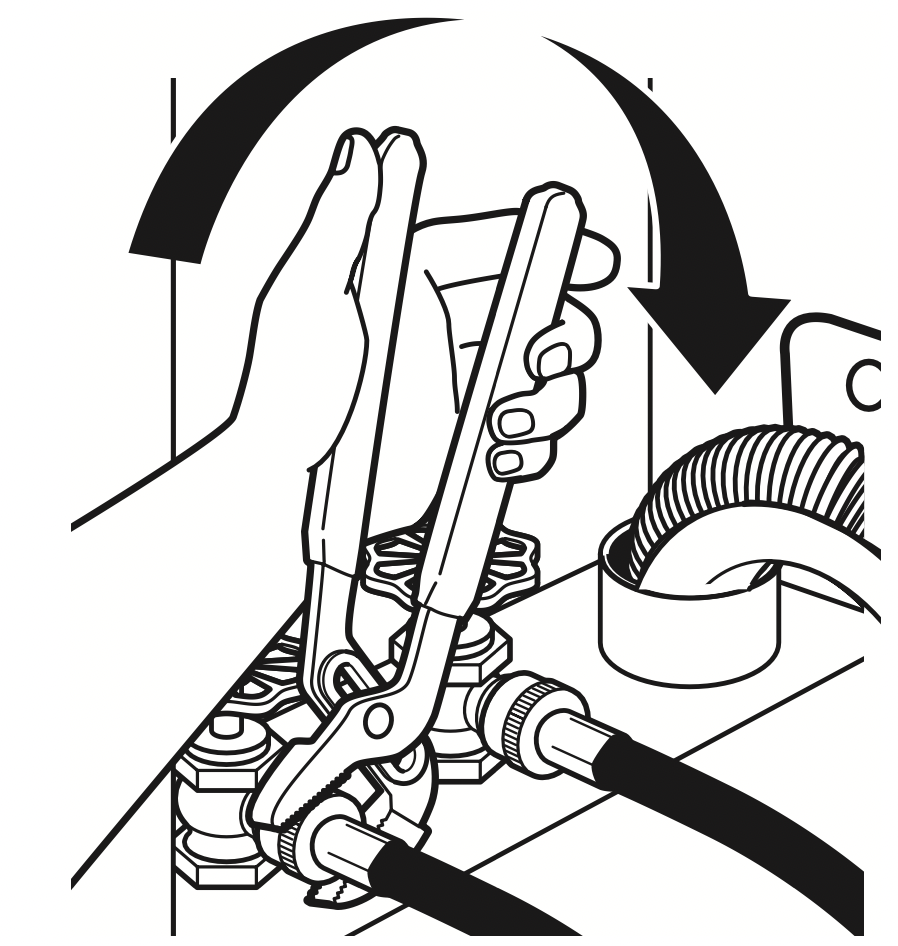

- Use pliers to tighten the couplings an additional two-thirds turn.

IMPORTANT: Do not overtighten or use tape or sealants on valve when attaching to faucets or washer. Damage can result. - Secure drain hose to inlet hose with zip strap.

Clear Water Lines

- Run water through both faucets and inlet hoses, into a laundry tub, drainpipe, or bucket to get rid of particles in the water lines that might clog the inlet valve screens.

- Check the temperature of the water to make sure that the hot water hose is connected to the hot water faucet and that the cold water hose is connected to the cold water faucet.

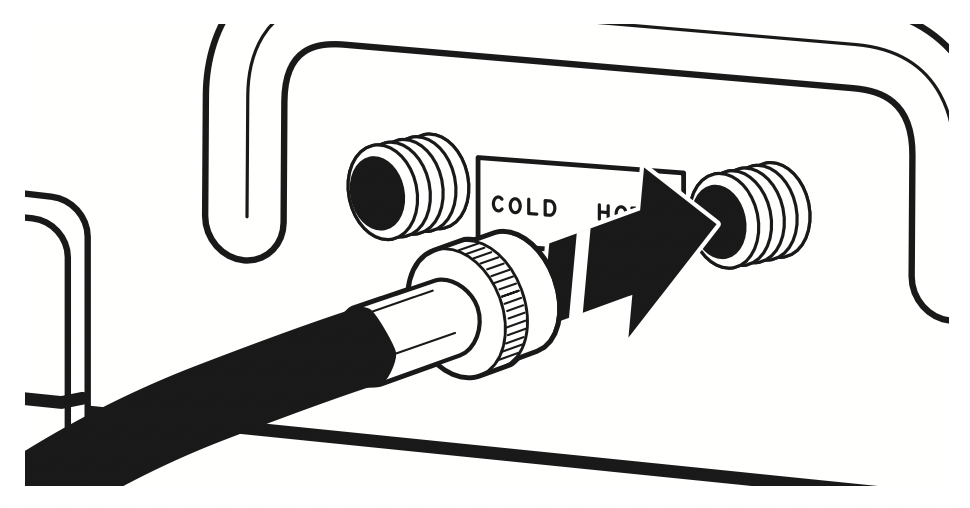

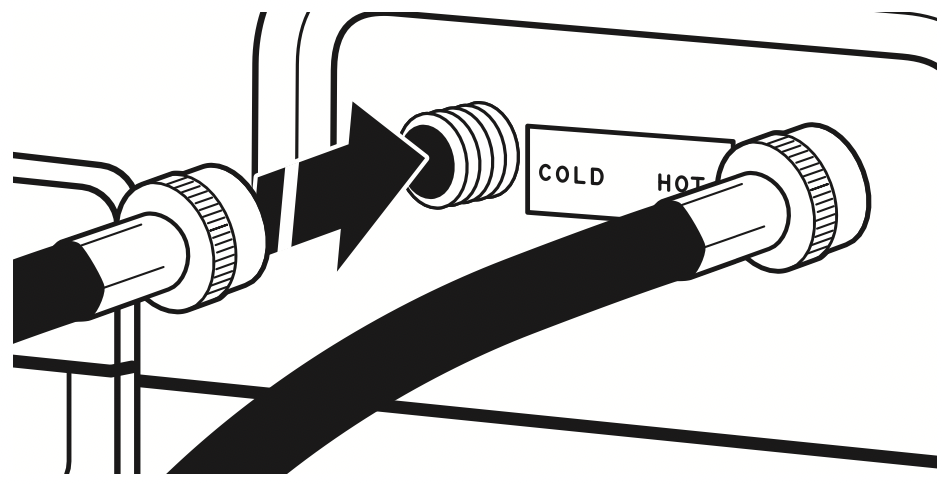

Connect Inlet Hoses to Washer

- Attach cold water hose to cold water inlet valve marked with a blue ring. Screw coupling by hand until it is snug.

- Attach hot water hose to hot water inlet valve marked with a red ring. Screw coupling by hand until it is snug.

- Use pliers to tighten couplings an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valve can result. - Turn on water faucets to check for leaks. A small amount of water may enter washer. It will drain later.

NOTE: Replace inlet hoses after 5 years of use to reduce the risk of hose failure. Record hose installation or replacement dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found.

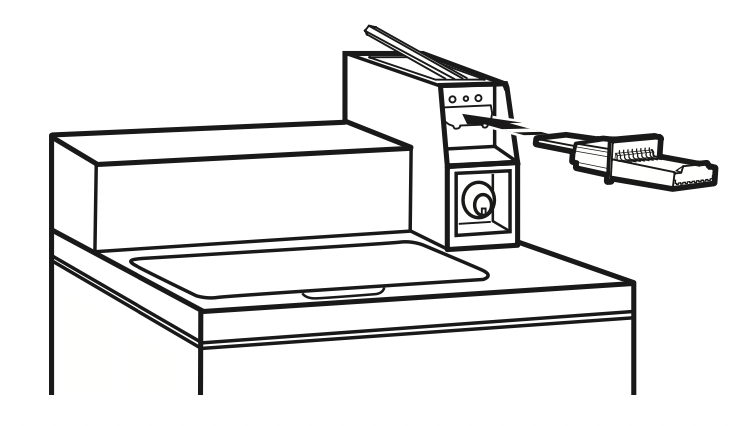

COMPLETE INSTALLATION

WARNING - Electrical Shock Hazard

- Plug into a grouded 3 prong outlet.

- Do not remove ground prong.

- Do not use an extension cord.

- Failure to follow these instructions can result in death, fire, or electrical shock.

Check electrical requirements. Be sure that you have the correct electrical supply and the recommended grounding method.

Check that all parts are now installed. If there is an extra part, go back through steps to see what was skipped.

Check that you have all of your tools.

Check that shipping materials were completely removed from washer.

Dispose of/recycle all packaging materials.

Check that the water faucets are on.

Check for leaks around faucets and inlet hoses.

Remove film from console and any tape remaining on washer.

Plug into a grounded outlet or connect power.

Check that circuit breaker is not tripped or fuse is not blown.

Start the washer using the payment system if used and check that the washer completes the cycle without a fault or water leak.

INSTALLING COIN SLIDE AND COIN BOX

The coin slide mechanism, service door lock and key, and coin box lock and key are not included with some models, but can be obtained from the usual industry sources.

Remove the service door of the meter case by lifting it up at the back. Install the money-accepting device. (Refer to manufacturer’s instructions for proper installation.)

A ground connection is needed for the coin slide, which can be made by connecting the available harness (W10846503) to the coin slide.

Install a lock and cam on the meter case service door. Install the coin vault with lock and key in the meter case opening.

WASHER MAINTENANCE

Operating Tips

WARNING - Fire Hazard

- Never place items in the washer that are dampened with gasoline or other flammable fluids.

- No washer can completely remove oil.

- Do not dry anything that has ever had any type of oil on it (including cooking oils).

- Doing so can result in death, explosion, or fire.

It is recommended that fiberglass items not be washed in coin-operated washers. If these items are washed in the washer, run the washer through a complete cycle to rinse any residue away that might be left in the washer.

Transporting Your Washer

- Shut off both water faucets. Disconnect and drain water inlet hoses.

- Disconnect drain from drain system and drain any remaining water into a pan or bucket. Disconnect drain hose from back of washer.

- Unplug power cord.

- Place inlet hoses and drain hose inside washer basket.

- Drape power cord over edge and into washer basket.

- Place packing tray from original shipping materials back inside washer and reuse shipping base to support the motor and tub. If you do not have original packaging, place heavy blankets or towels above basket, between the washer top and the tub ring. Close lid and place tape over lip and down the front of the washer. Keep lid taped until washer is moved to new location.