Loading ...

Loading ...

Loading ...

13

EN

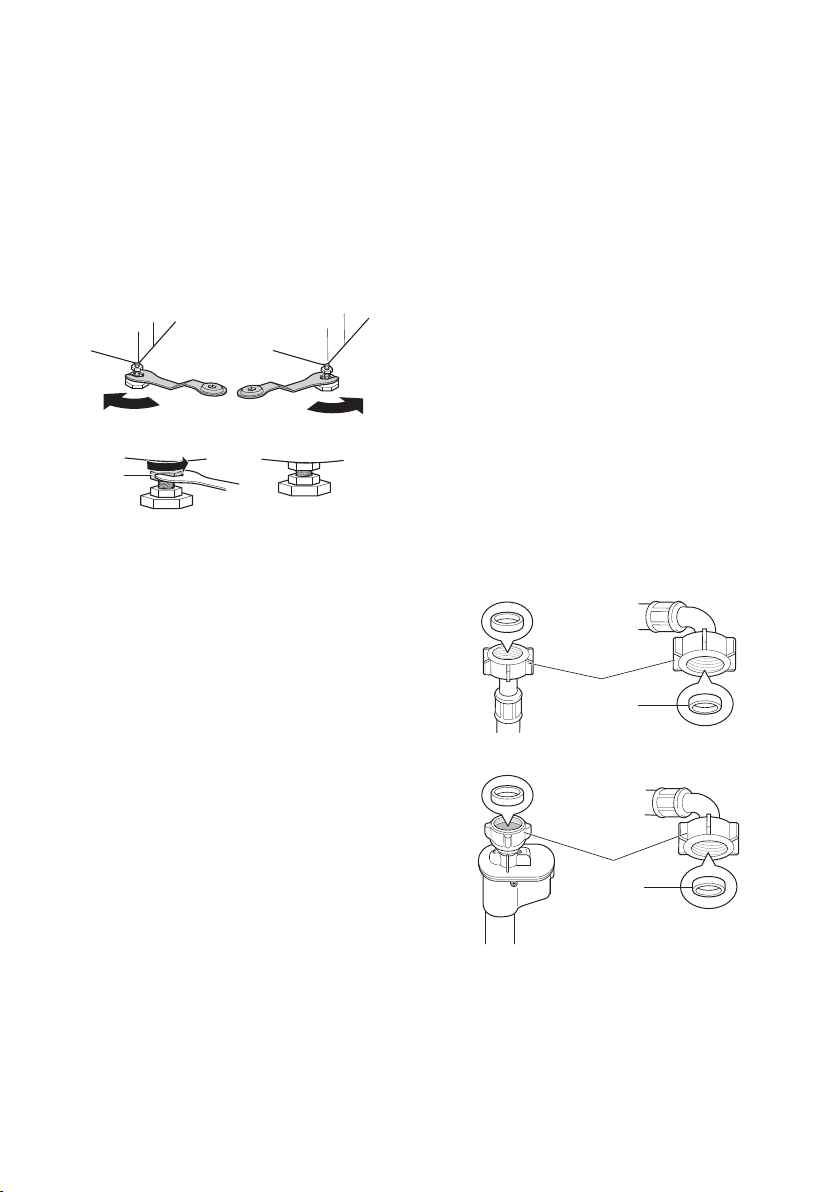

Leveling the Appliance

If the floor is uneven, turn the adjustable feet as

required (Do not insert pieces of wood etc.

under the feet). Make sure that all four feet are

stable and resting on the floor and then check

that the appliance is perfectly level (Use a spirit

level).

• Once the appliance is level, tighten the lock

nuts up towards the base of the appliance. All

lock nuts must be tightened.

Raise Lower

Lock nut

Tighten all 4

lock nuts securely

Diagonal Check

• When pushing down on the edges of the top

plate diagonally, the appliance should not

move up and down at all (check both

directions). If the appliance rocks when

pushing the machine top plate diagonally,

adjust the necessary foot or feet again.

NOTE

• Timber or suspended type flooring will

contribute to excessive vibration and

unbalance. Re enforcement or bracing of the

timber floor may need to be considered to

stop or reduce excessive noise and vibration.

• Do not install the washer on any elevated

surface, stand or plinth as it can become

unstable and fall causing serious injury and

damage.

Connecting the Water Supply

Hose

• Water pressure must be between 100 ~

800kPa (1.0‒8.0 kgf/cm

2

).

• Do not strip or crossthread when connecting

supply hose to the valve.

• If the water pressure is more than 800 kPa, a

pressure limiting device should be installed.

• Periodically check the condition of the hose

and replace the hose if necessary.

Checking the Rubber Seal on the

Water Supply Hose

Two rubber seals are supplied with each water

inlet hose. They are used for preventing water

leaks. Make sure the connection to taps is

sufficiently tight. Do not use any mechanical

device to overtighten the inlet hoses. Hand

tighten only with the aid of a soft cloth if

necessary. After both ends have been

connected, open the taps slowly and check for

leaks.

Hose connector

Rubber seal

Hose connector

Rubber seal

Loading ...

Loading ...

Loading ...