Loading ...

Loading ...

Loading ...

English

10

Blade Tracking (Fig. A, H)

WARNING: To reduce the risk of serious personal

injury, turn tool off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start‑up can causeinjury.

NOTICE: Excessive tightening of the adjustment screws

could result in damage to thesaw.

Your band saw is equipped with an adjustable blade tracking

mechanism which assures proper blade tracking at all times.

The blade is properly adjusted when it is sitting fully on

rubber tires

21

and lightly touching one or both of the rear

guide bearings

25

.

To Adjust the Blade Tracking (Fig. A, H)

1. Turn and open the blade tension lever

8

to allow access

to the tracking screw

13

.

2. Use a 13mm wrench to loosen the lock nut

7

(Fig.H).

3. Use a 4mm hex wrench

5

to turn the tracking screw

13

1/4 turn clockwise or counterclockwise (Fig.H).

nOTE: Turning the tracking screw clockwise moves

the blade toward the guide roller, turning the tracking

screw counterclockwise moves the blade away from the

guideroller.

4. Tighten the locking nut and close the blade tension lever

and blade guard. (It will be necessary to run the saw to

observe the tracking.)

5. Observe blade tracking between runs and repeat Steps

1–4 as necessary to achieve proper bladetracking.

4. When removing the blade, tension may be released and

the blade may spring free. SAW BLADES ARE SHARP. USE

CARE IN HANDLINGTHEM.

5. Inspect the guide rollers

20

and remove any large chips

which may be lodged in them. Lodged chips can prevent

rotation of the guide rollers and cause flat spots on the

guiderollers.

6. Rubber tires

21

are mounted on the pulleys

19

. The

rubber tires should be inspected for looseness or damage

when changing the blade. Wipe any chips from the

rubber tires on the pulleys with abrush.

nOTE: Do not use your hands to wipechips.

This will extend tire life and keep the blade from slipping.

If any looseness or damage occurs, the tool should be

brought to an authorized DeWALT service center for

repair or replacement as soon as possible. Continued use

of the tool with loose or damaged rubber tires will cause

unstable travel of the band sawblade.

7. Close the blade guard and securely latch the two

blade guard latches. Rotate the blade tension lever

8

counterclockwise 180degrees until itstops.

Installing and Removing Blades

CAUTION: Cut hazard. Blade tension lever is under

spring pressure. Maintain control of lever when

releasing bladetension.

WARNING: ALWAYS wear gloves when touching the

sawblade.

To Install Blade (Fig. A, D–G)

1. Rotate the blade tension lever

8

clockwise 180degrees

until it stops to release tension on blade (refer to

FigureA).

2. Turn the saw over and place it on a workbench ortable.

3. Unlatch the two blade guard latches

12

and open the

bladeguard.

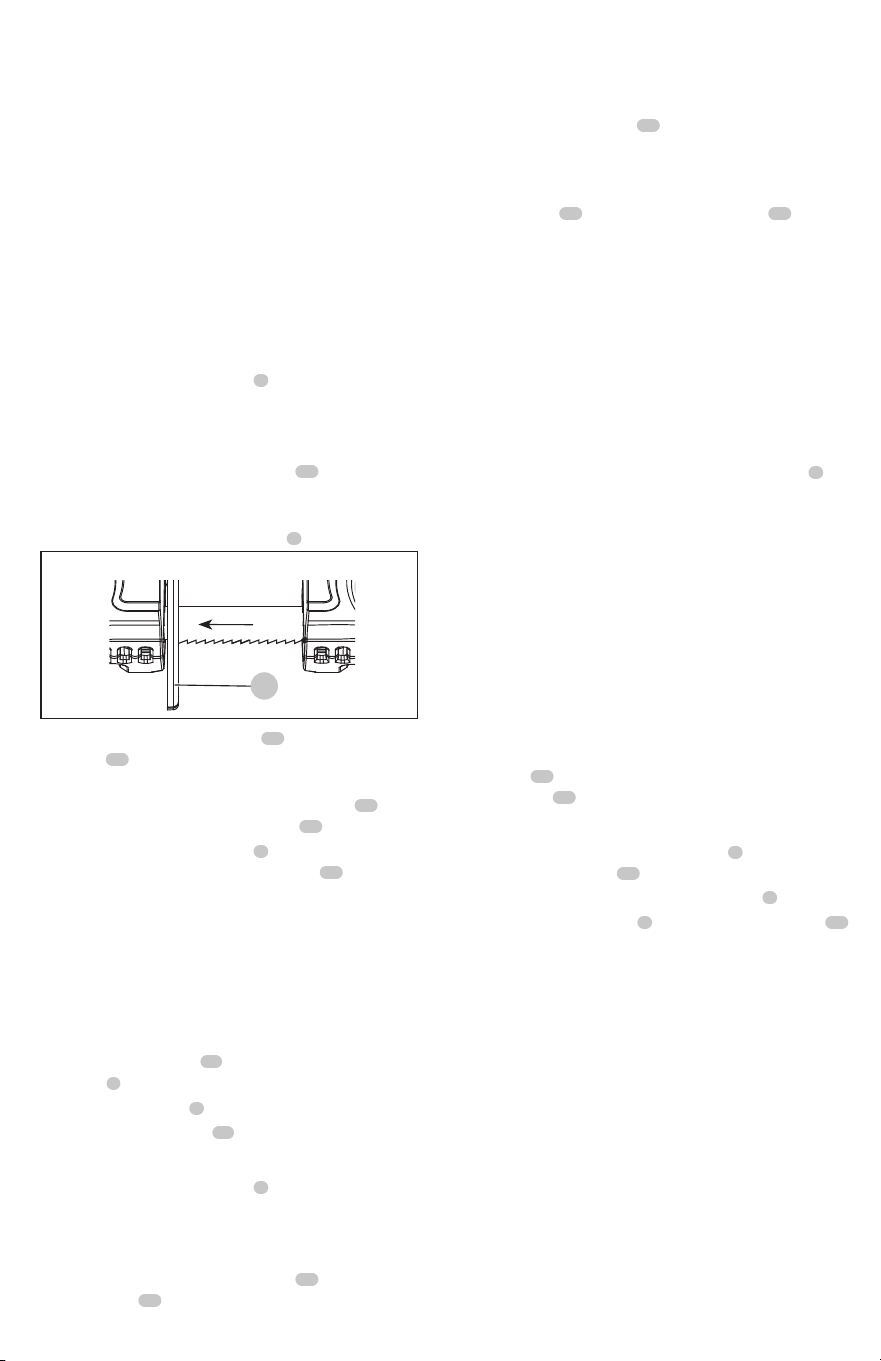

4. Position the blade so that the teeth face out from the

saw and cut towards the work stop

6

.

blade direction

6

5. Slip blade into the guide rollers

20

and around both

pulleys

19

as shown in FigureD.

6. Make sure that the blade is fully inserted into the guide

rollers and positioned fully on the rubbertires

21

and

just touching the rear guide bearings

25

.

7. Rotate the blade tension lever

8

counterclockwise

until it stops and then close blade guard

11

and secure

latches. Make sure the teeth face away from the band

saw (as shown in the Figure in Step4).

8. Turn the saw on and off a few times to ensure that the

blade is seatedproperly.

Work Stop Adjustment (Fig. G)

To support large workpieces, the work stop should be

lowered following these steps:

1. Loosen the two screws

26

, shown in Figure G, with the hex

wrench

5

provided.

2. Move the work stop

6

to the desiredposition.

3. Securely tighten screws

26

.

To Remove Blade (Fig. A, D–H)

1. Rotate the blade tension lever

8

clockwise 180degrees

until it stops to release tension in blade (refer to

FigureA).

2. Turn the saw over and place it on a workbench ortable.

3. Unlatch the two blade guard latches

12

and open the

bladeguard

11

.

ASSEMBLY AND ADJUSTMENTS

WARNING:

To reduce the risk of serious personal

injury, turn unit off and

remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An accidental

start‑up can causeinjury.

Blades

This portable band saw is set up for use with

0.02" (0.5mm) thick, 1/2" (12.7 mm) wide and

35‑1/4"–35‑3/8" (896 mm–899 mm) long blades. DO nOT

use 0.025" (0.64mm) thickblades.

Loading ...

Loading ...

Loading ...