Loading ...

Loading ...

Loading ...

Controls & Operation

4

7

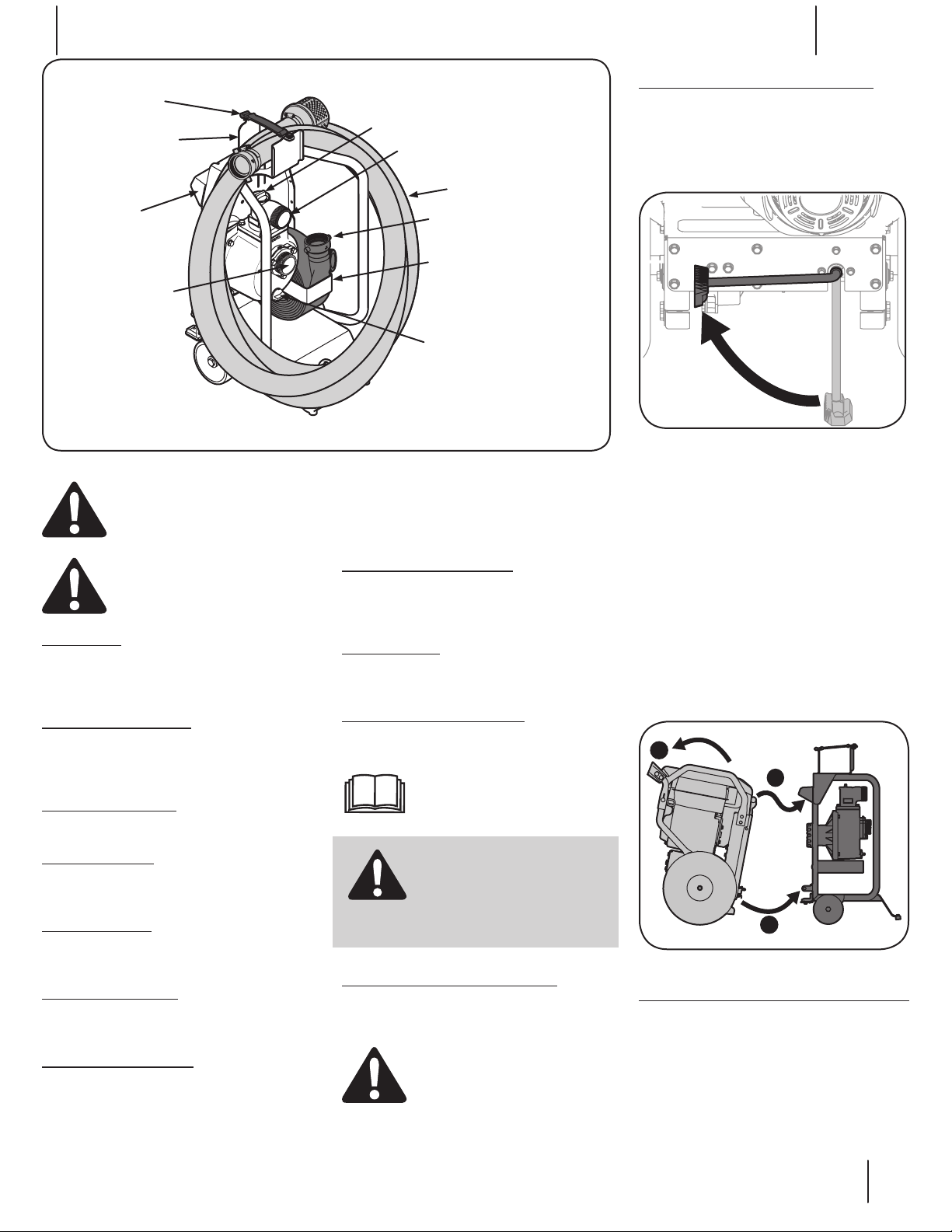

Primer Filler Plug

Discharge Port (2” NPT)

Suction Port (2” NPT)

Water Drain Plug

Rear Handle

Suction Hose Storage

Discharge Hose Storage

Suction Hose with Strainer

Discharge Hose

Suction Hose

Tie Down Strap

Figure 4-1

WARNING! Read and follow all safety rules and instructions in this manual, including the

entire Controls & Operation section, before attempting to operate this machine. Failure to

comply with all safety rules and instructions may result in personal injury.

WARNING! This attachment weighs

61 lb. and requires two people to lift it.

Rear Handle

The rear handle should be used to move the water

pump around when NOT attached to the FLEX™

Power Base.

Discharge Port (2” NPT)

Connects discharge hose to the pump. Can be

rotated 90° left or right to adjust the angle of water

discharge.

Suction Port (2” NPT)

Connects suction hose to the pump.

Primer Filler Plug

Remove plug to fill pump chamber with water to

prime the water pump for each use.

Water Drain Plug

Remove plug to drain water and sediment from

inside the pump after use.

Suction Hose Storage

Used for storing the suction hose with strainer

when not in use.

Discharge Hose Storage

The bracket located next to the pump allows for

safe and secure storage of the discharge hose.

Suction Hose with Strainer

Rigid hose construction with threaded end for

connection to Suction Port on pump, with a

strainer end for submersion into a water source.

Discharge Hose

Flexible lay flat hose construction with threaded

end for connection to Discharge Port on pump.

Suction Hose Tie Down Strap

Used to help secure the suction hose with strainer.

Read the entire Operator’s Manual

before you attempt to operate your

new water pump.

Starting and Stopping the Engine

Start and stop the engine on the FLEX™ Power

Base in accordance with the Operator’s Manual

included with that machine.

WARNING! If leaving this equipment

unattended turn the engine OFF and

remove the ignition key.

Connecting to the FLEX™ Power Base

NOTE: All references to the left or right side are from

the operator’s position. Any exceptions will be noted.

1. Roll the FLEX™ Power Base over to the water

pump attachment with the kickstand UP.

See Figure 4-2.

Figure 4-2

2. Roll the FLEX™ Power Base forward and tip it

up, engaging the top part of the water pump

attachment with the handle mount provided

on the FLEX™ Power Base (1 of Figure 4-3).

3. Tip the FLEX™ Power Base backwards to

engage the two bottom connection points

(2 and 3 of Figure 4-3).

Note: The operator will be able to hear the

lower mounts engage and lock (latching

sound) when coupled properly. To test if

coupled properly, lift up on the handles. If

the unit comes apart, the connection was

not made. Ensure that the kickstand is still

in the UP position, and swiftly tip the FLEX™

Power Base backward with the top mount

engaged.

1

3

2

Figure 4-3

Disconnecting from the FLEX™ Power Base

1. The kickstand acts only as a locking device

for the attachment to the FLEX™ Power Base.

The only time the operator would need

to deploy the kickstand once connected

to an attachment would be in the case of

uncoupling the FLEX™ Power Base from the

attachment.

CAUTION! When the FLEX™ Water

Pump attachment is attached to

the FLEX™ Power Base, the engine

should be started after the water

pump has been primed. We do not

recommend running the pump dry.

Loading ...

Loading ...

Loading ...