Loading ...

Loading ...

Loading ...

8 Section 4— controlS & operation

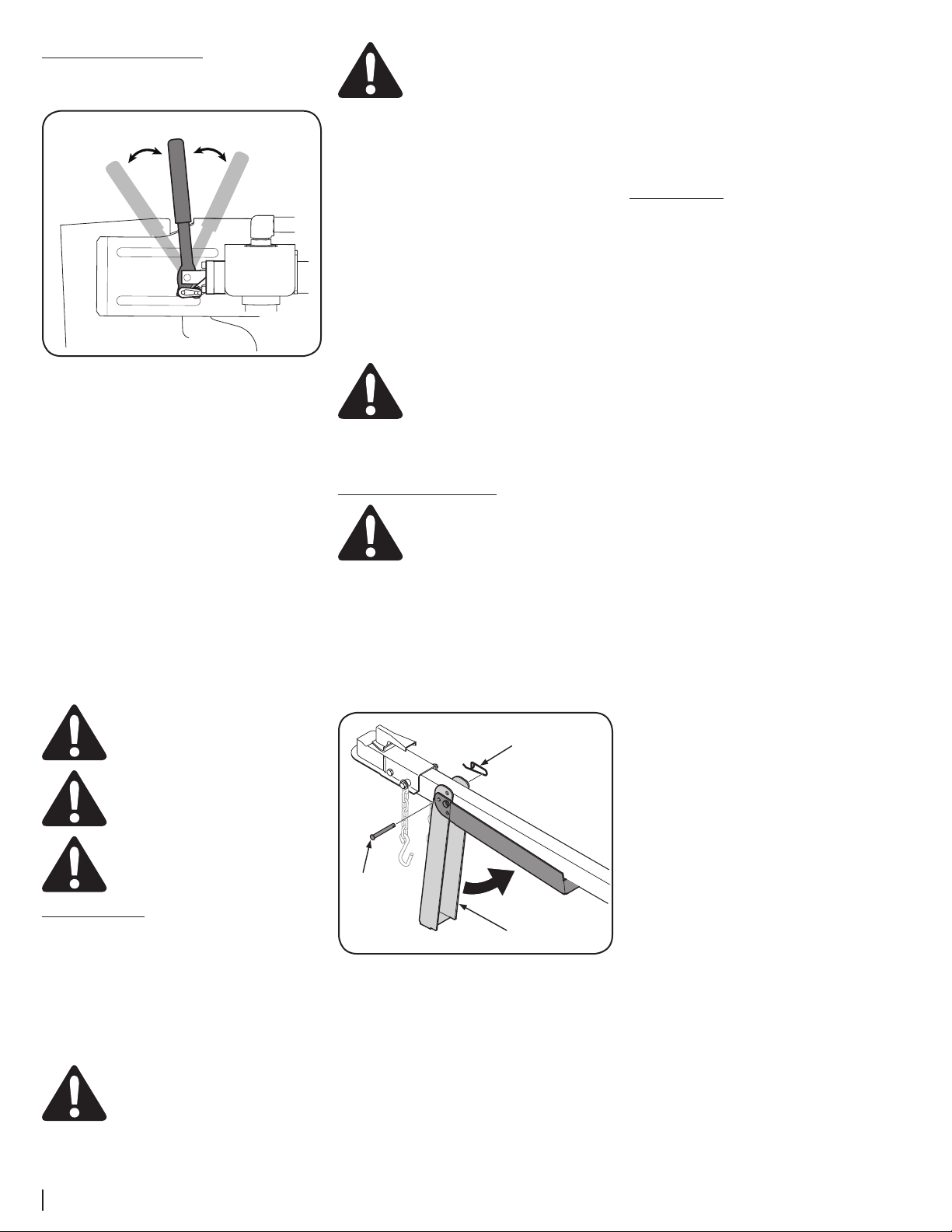

Using the Control Handle

The control handle has three positions. See Figure

4-5.

Neutral

(To stop wedge)

Forward

(To split wood)

Reverse

(To return wedge)

Figure 4-5

• FORWARD — Move the control handle to the

FORWARD position to move wedge toward the

log to split.

NOTE: The control handle will return to the

NEUTRAL position as soon as the handle is

released (FORWARD position only).

• NEUTRAL — Release the control handle or

move the lever to the NEUTRAL position to

stop the wedge movement.

• REVERSE — Move the control handle to the

REVERSE position to return the wedge toward

the cylinder. The control handle stays in the

REVERSE position and returns to the NEUTRAL

position automatically when fully retracted. Do

not hold the handle in the REVERSE position

when fully retracted.

NOTE: The REVERSE position may also

be moved back to the NEUTRAL position

manually, if necessary.

WARNING! If the control handle on your

log splitter is not functioning properly,

STOP USE IMMEDIATELY and contact an

authorized service dealer.

WARNING! Do not attempt to service,

repair or replace control valve. Contact

an authorized service dealer.

WARNING! Do not attempt to adjust or

modify the control valve or the

hydraulic system from its original

settings or manufacture in any way.

Splitting the Wood

1. Start the engine as instructed in the Engine

Operator’s manual included with the log

splitter.

2. Place the log against the end plate and only

split the wood in the direction of the grain.

3. To stabilize the log, place your left hand on the

side of the log opposite the beam as shown in

Figure 4-2.

WARNING! Never place a hand on the

ends of the log, between the log and

the end plate, or the log and the

splitting wedge.

WARNING! Only one operator

permitted. The adult who loads and

stabilizes the log, must be the person

who operates the control handle.

4. Move the control handle to the forward

position to split the wood.

5. Remove left hand from the side of the log

once wedge just contacts the log. Continue

moving control handle forward to split the

log.

6. Release the control handle to stop the wedge

movement.

7. Move the control handle to the reverse

position to return the wedge.

8. To remove partially split wood from wedge,

move the control handle to the REVERSE

position until the wedge is fully retracted to

allow split wood portion to contact the log

dislodger.

WARNING! Never remove partially

split wood from the wedge with your

hands. Fingers may become trapped

between the split wood.

9. Once removed from the wedge with the log

dislodger, split the wood from the opposite

end or in another location.

Transporting the Log Splitter

WARNING! Do not tow faster than

45mph and check the local, state and

federal requirements before towing

on any public road.

1. Lower the beam to its horizontal position.

Make certain the beam is locked securely with

the horizontal beam lock.

2. Remove the spring clip and clevis pin from

the jack stand.

3. Support the tongue and pivot the jack stand

up against the tongue. See Figure 4-6.

Spring Clip

Clevis Pin

Jack Stand

Figure 4-6

4. Secure with the spring clip and clevis pin

previously removed. See Figure 4-6.

5. Attach the coupler hitch to a class I or higher

2” ball on the towing vehicle; latch securely.

a. If the coupler hitch does not fit on the

ball, turn the adjustment nut one turn

counter-clockwise.

b. If the coupler hitch is too loose on the

ball, turn the adjustment nut one turn

clockwise. Then recheck and adjust

accordingly.

6. Connect the safety chains to the towing

vehicle.

NOTE: Use caution when backing up, a spotter

outside the vehicle is recommended.

Operating Tips

Always:

1. Use clean fluid and check the fluid level

regularly.

2. Use an approved hydraulic fluid. Approved

fluids include Shell Tellus® S2 M 32 Hydraulic

Fluid, Dexron® III/Mercon® automatic

transmission fluid, Pro-Select™ AW-32

Hydraulic Oil or 10WAW-ISO viscosity grade 32

hydraulic oil.

NOTE: It is recommended that fluids not be

mixed.

3. Use a filter (clean or replace regularly).

4. Use a breather cap on fluid reservoir.

5. Make sure the pump is mounted and aligned

properly.

6. Use a flexible “spider” type coupling between

the engine and pump drive shafts.

7. Keep the hoses clear and unblocked.

8. Bleed the air out of the hoses before

operating.

9. Flush and clean the hydraulic system before

restarting after servicing.

10. Use pipe dope only on tapered pipe threads.

11. Allow time for the engine to warm up before

splitting wood.

12. Prime the pump before the initial start-up by

turning over the engine with the spark plug

disconnected (if not already done at factory).

13. Split wood along the grain (lengthwise) only.

Never:

1. Use when fluid is below 20° F or above 150° F.

2. Use a solid engine/pump coupling.

3. Operate through relief valve for more than 5

seconds.

4. Attempt to adjust the unloading or relief valve

settings.

5. Operate with air in hydraulic system.

6. Use Teflon tape on hydraulic fittings.

7. Attempt to cut wood across the grain.

8. Attempt to remove partially split wood from

the wedge with your hands. Instead, fully

retract the wedge to dislodge wood with log

dislodger.

Loading ...

Loading ...

Loading ...