Loading ...

Loading ...

Loading ...

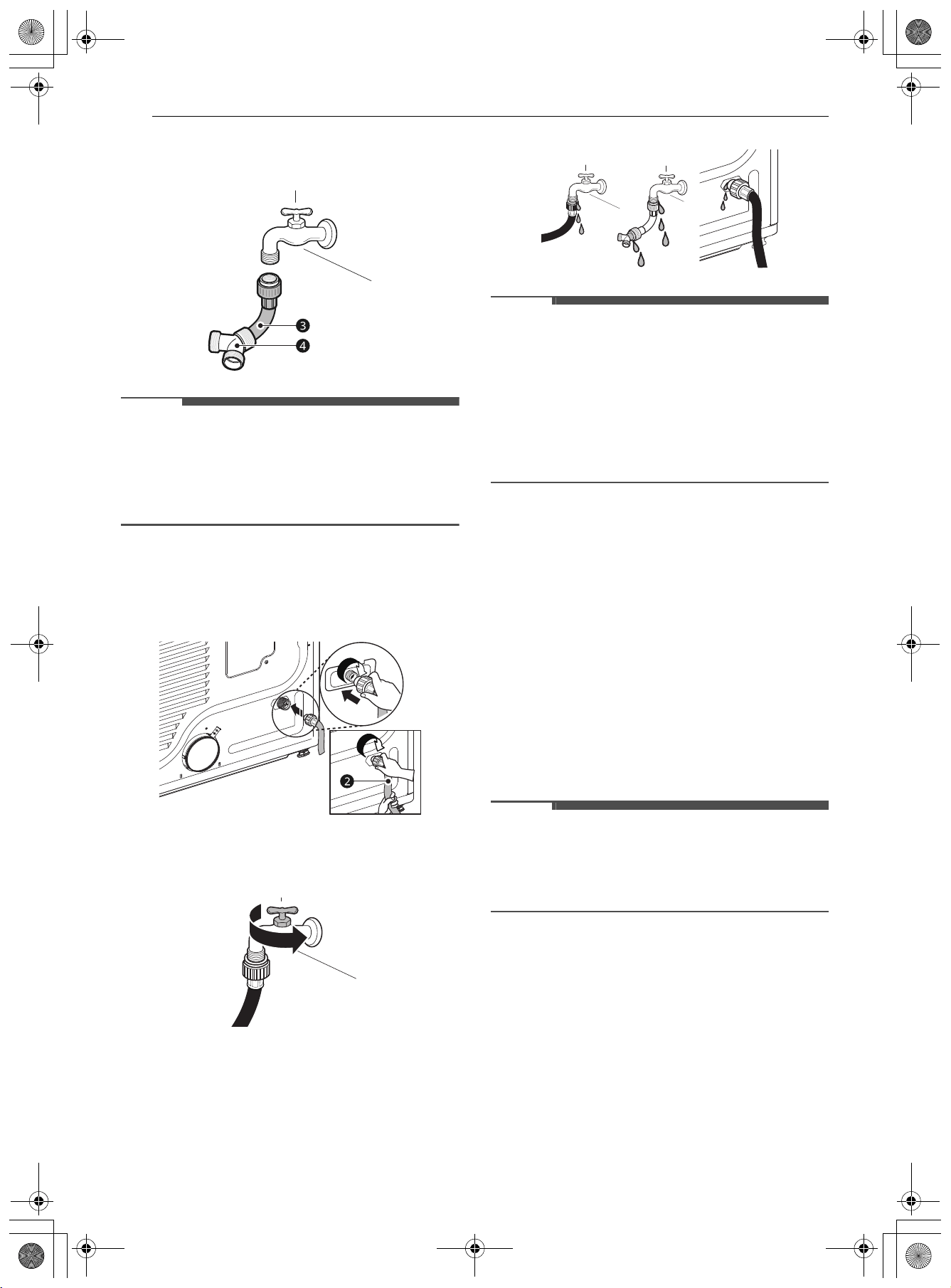

30 INSTALLATION

washer hose to the washer and the

other side of the Y-connector d.

NOTE

• Before connecting the water line to the dryer,

flush several gallons of water into a drain or

bucket. This will help prevent foreign particles

such as sand and scale from clogging the dryer

inlet valve.

3 Connect the long dryer hose b to the dryer

inlet valve tightly by hand and then tighten

another 2/3 turn with pliers.

4 Turn on the cold water faucet.

5 Check all hoses and Y-connectors (if used) for

leaks.

NOTE

• If any leaks are found, shut off the water faucet,

remove the hose and check the condition of the

rubber seal.

• In areas with hard water, mineral scale can form

on internal components of the dryer. Use of a

water softener is recommended in areas with

hard water. Excessive scale buildup may lead to

the need for certain part replacement or repair.

Final Installation Check

Once you have completed the installation of the

dryer and it is in its final location, confirm proper

operation with the following tests.

Test Dryer Heating

Gas Models

Close the dryer door and press the Power button

to turn the dryer on. Turn the knob to select Timed

Dry and press the

8(OK) button to start the test.

When the dryer starts, the igniter should ignite the

main burner.

NOTE

• If all air is not purged from the gas line, the gas

igniter may turn off before the main burner

ignites. If this happens, the igniter will reattempt

gas ignition after approximately two minutes.

Electric Models

Close the dryer door and press the Power button

to turn the dryer on. Turn the knob to select Timed

Dry and press the

8(OK) button to start the test.

The exhaust air should be warm after the dryer

has been operating for 3 minutes.

Checking Airflow

Effective dryer operation requires proper airflow.

The adequacy of the airflow can be measured by

evaluating the static pressure. Static pressure in

en-us_main.book.book Page 30 Tuesday, December 12, 2023 12:59 PM

Loading ...

Loading ...

Loading ...