Loading ...

Loading ...

Loading ...

17

SERVICE AND MAINTENANCE

Use a clean lubricating oil (#30 weight motor oil is suitable) and a clean general

purpose grease (grease containing a metal lubricant is preferred, if available).

• Remove the wheels, clean the wheel shaft and apply a thin coating of grease

to the wheel shaft.

• Grease the back, front and sides of the depth regulator lever.

• Remove the tines and clean the tine shaft. Use a file or sandpaper to gently

remove any rust, burrs or rough spots (especially around holes in the shaft).

Apply grease to the ends of the shaft before installing the tines.

• Oil the threads on the handlebar height adjustment screws and the

handlebar attaching screws.

Transmission Gear Oil

Check the transmission gear oil after every 30 hours of operation or whenever you

notice any oil leak. Operating the tiller when the transmission is low on oil can result

in severe damage.

To Check the Transmission Gear Oil Level:

1. Check the gear oil level when the transmission is cool. Gear oil will expand in

warm operating temperatures and this expansion will provide an incorrect

oil level reading.

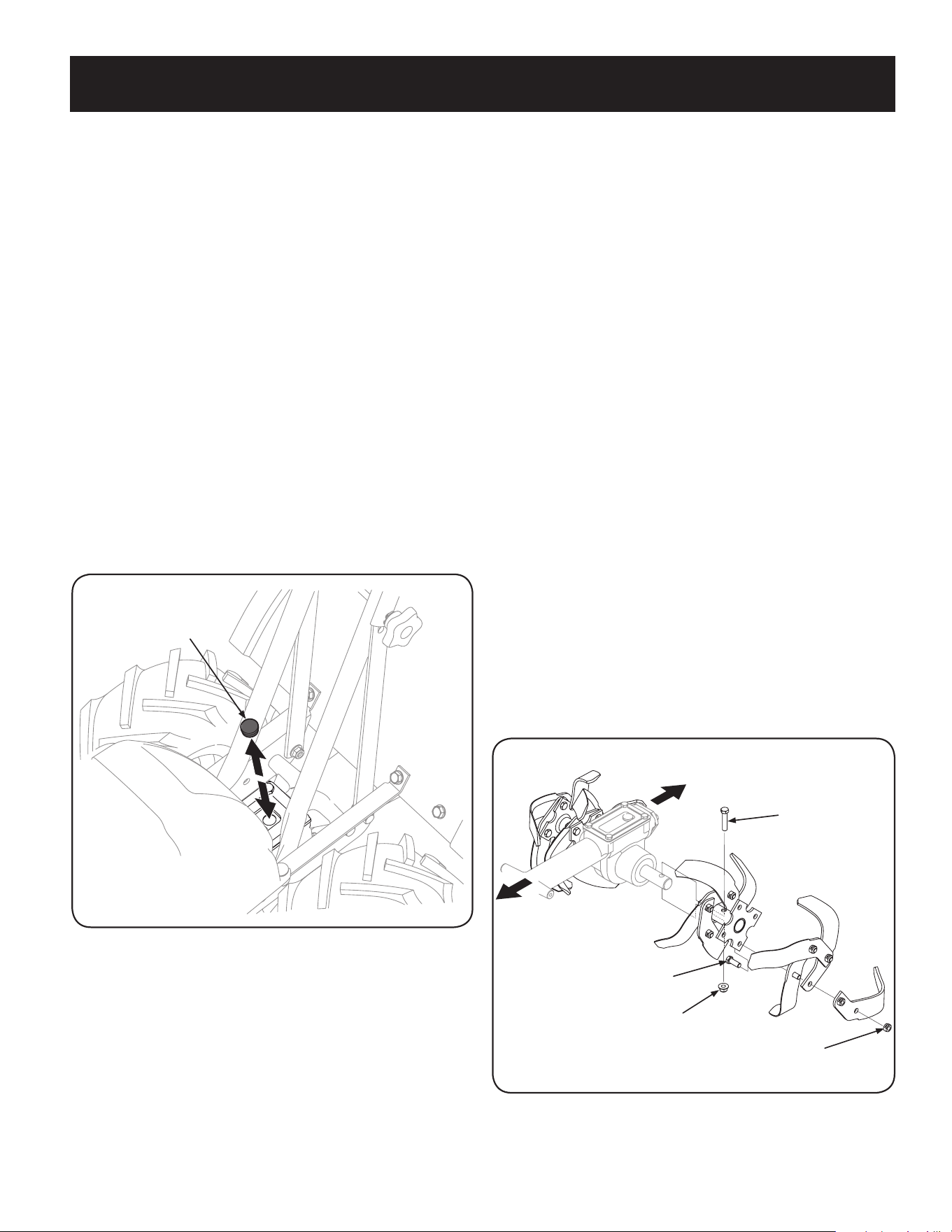

2. With the tiller on level ground, pull the Depth Regulator Lever all the way up.

3. Clean the area around the oil fill plug. See Figure 24.

Oil Fill Plug

Figure 24

4. Remove the oil fill plug from the transmission housing and look inside the oil

fill hole to locate the main drive shaft situated below the hole. See Figure 24.

5. The gear oil level is correct if the gear oil is approximately halfway up the

side of the main drive shaft.

6. If the gear oil level is low, add gear oil as described next. If the gear oil level

is okay, securely replace the oil fill plug.

7. When adding gear oil, use Mobil 1® Synthetic 75W 140.

8. While checking frequently to avoid overfilling, slowly add gear oil into the oil

fill hole until it reaches the halfway point on the drive shaft.

9. Securely replace the oil fill plug.

Belt Replacement

If the drive belt or reverse drive belt needs to be replaced, see your local authorized

dealer or refer to the Replacement Parts Section for ordering information. Use only a

factory-authorized belt as an “over- the-counter” belt may not perform satisfactorily. The

procedure requires average mechanical ability and commonly available tools.

NOTE: When reinstalling the belt cover, be sure to engage the bail and hold

it so that the drive belt is tight before attempting to reinstall the belt cover.

This will enable the belt to fall under the belt keeping mechanism built into

the belt cover. Failure to do so could damage the belt and/or belt cover.

Tines

The bolo tines will wear with use and should be inspected at the beginning of

each tilling season and after every 30 operating hours. The tines can be replaced

either individually or as a complete set. See the Replacement Parts Section for tine

identification and part numbers.

Tine Inspection

With use, the tines will become shorter, narrower and pointed. Badly worn tines will

result in a loss of tilling depth, and reduced effectiveness when chopping up and turning

under organic matter.

Refer to Figure 25 for the following tine procedures.

Front/Forward

Rear/Operator

Hex Screw

Flange Lock Nut

Hex Lock Nut

Hex Screw

Figure 25

Loading ...

Loading ...

Loading ...