Loading ...

Loading ...

Loading ...

MAINTENANCE (Continued)

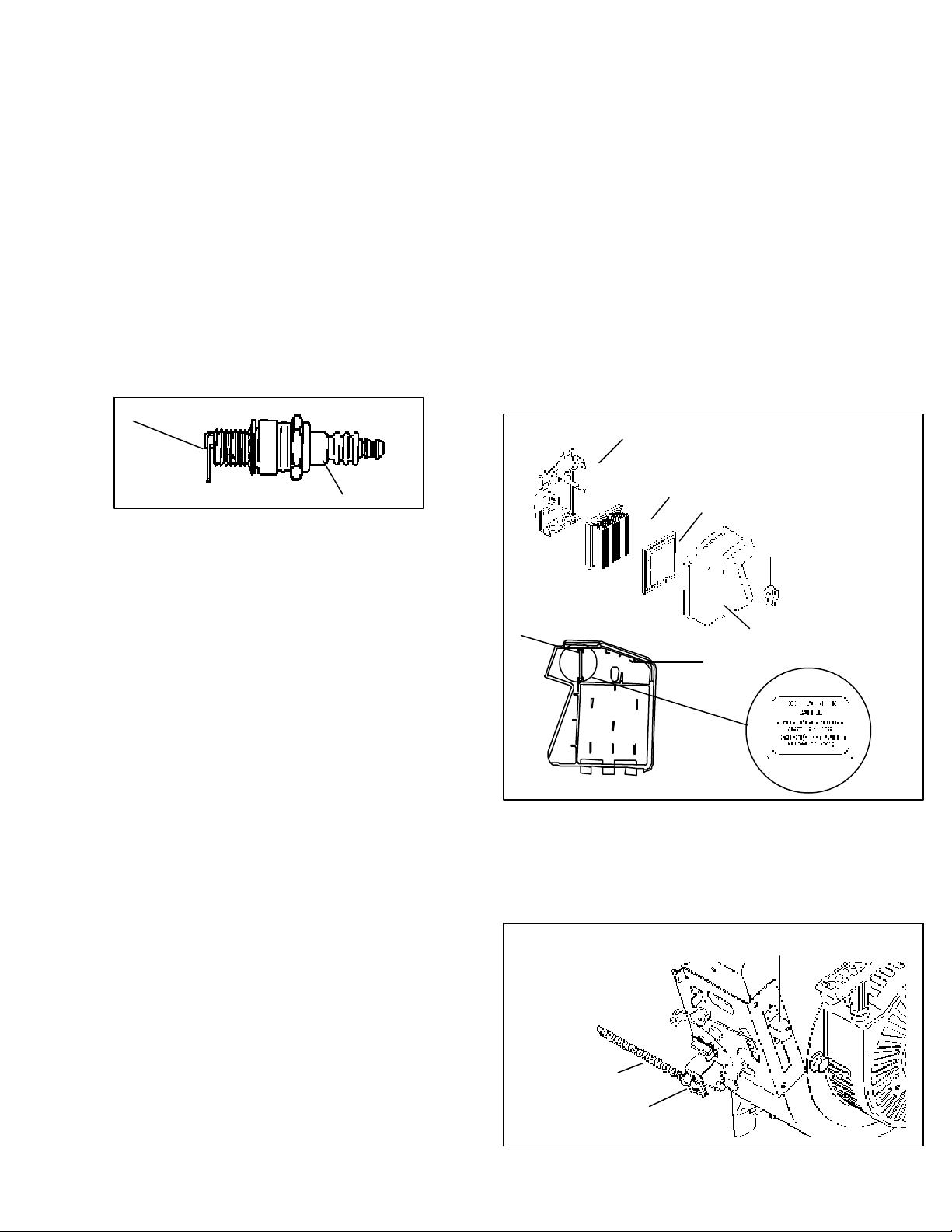

C. ANTI-ICING BAFFLE

Some engines may be equipped with an anti-icing air cleaner

feature to enable the engine to run at temperatures below 32

0

F

(0

0

C), without ice forming in the carburetor.

If so equipped, the air cleaner base will have an opening which

draws warm air from the muffler into the air cleaner housing. To

work effectively, it is necessary to block cold air from entering

the air cleaner.

IN TEMPERATURES 32

0

F (0

0

C) AND BELOW: (See figure

6)

1. Remove wing nut from air cleaner cover.

2. Remove air cleaner cover from base.

3. Remove red baffle from inside of air cleaner cover.

4. Insert red baffle in "winter" position shown.

5. Reinstall air cleaner cover onto base.

6 Reinstall wing nut; tighten securely.

IN TEMPERATURES ABOVE 32

0

F (0

0

C):

Follow above directions, removing baffle from "winter" position

and reinstalling in "summer" position.

Page 4 181-1032-14

Figure 7

HIGH SPEED

POSITION

REMOTE CABLE

CABLE CLAMP

BASE

PAPER ELEMENT

COVER

WING NUT

FOAM FILTER (IF SO EQUIPPED)

ÅÅ ALTERNATOR AND BATTERY (if so equipped):

A. ALTERNATOR:

For electrical problems such as inoperative starter or

discharged battery see equipment manufacturer’s

instructions for fuse replacement, maintenance and repairs.

Figure 6

RED BAFFLE SHOWN IN

"WINTER" POSITION

ANTI-ICING FEATURE (IF SO EQUIPPED)

RED BAFFLE "SUMMER" POSI-

TION

RED BAFFLE

MAINTENANCE (Continued)

ÃÃ SPARK PLUG (see Figure 5):

NOTE: This spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

NOTE: This engine complies with all current Australian and New Zealand limi-

tations regarding electromagnetic interference.

NOTE: This engine complies with the European standard for safety of garden

equipment and powered lawnmowers EN836, Revision March, 1997, and appli-

cable sections of the EU Machinery Safety Directives.

Check spark plug yearly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned, fouled with

deposits, or porcelain is cracked. For replacement use

Champion RN4C only.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at

.030 if necessary.

E. Install spark plug, tighten securely.

ÄÄ AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE

AIR CLEANER INSTALLED ON ENGINE.

A. TO REMOVE AND INSTALL FILTER(S) (see Figure 6):

1. Remove wing nut and cover. Remove paper element.

2. Remove and inspect foam filter (if so equipped) for

discoloration or dirt accumulation. If either is present,

service per following “TO SERVICE FILTER(S)”

instructions.

3. Clean inside of base and cover thoroughly.

4. Replace foam filter (if so equipped), making sure the

screen side is towards the paper element. Then tighten

wing nut securely.

B. TO SERVICE FILTER(S) (see Figure 6):

1. FOAM FILTER:

Clean and re-oil every three (3) months or every 25

operating hours. Clean and re-oil daily if used in

extremely dusty conditions.

a. Wash in water and detergent solution and squeeze

(don't twist) until all dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don't twist) until

completely dry.

d. Saturate with engine oil and squeeze (don't twist) to

distribute oil and remove excess oil.

2. PAPER FILTER:

Replace once a year or every 100 operating hours,

more often if used in extremely dusty conditions.

Replacement filters are available at any Authorized

Tecumseh Service Outlet.

Figure 5

ELECTRODES

.030 GAP

PORCELAIN

Loading ...

Loading ...

Loading ...