Loading ...

Loading ...

Loading ...

15

- All Markets

NOTE: (*) Measure burner operating pressure at the manifold pressure test point with the main burner

operating at 'High Flame' setting. Operating pressure is ex-factory set, through the appliance

regulator and is not to be adjusted, apart from when carrying out gas conversion, if required. Refer

to the details in this section for further details.

Main Burner Injectors

Ø 1.00mm Ø 0.65mm

Main Burner Injectors (Qty)

18 18

Main Burner Primary Air

6.0mm 6.0mm

Pilot Burner Injector

0.35mm

Fully In (C.W)

0.35mm

Fully In (C.W)

Supply Pressure

1.13 - 3.40 kPa 2.75 - 4.50 kPa

Burner Operating Pressure (*)

1.00 kPa 2.65 kPa

Gas Regulator Cap Screw

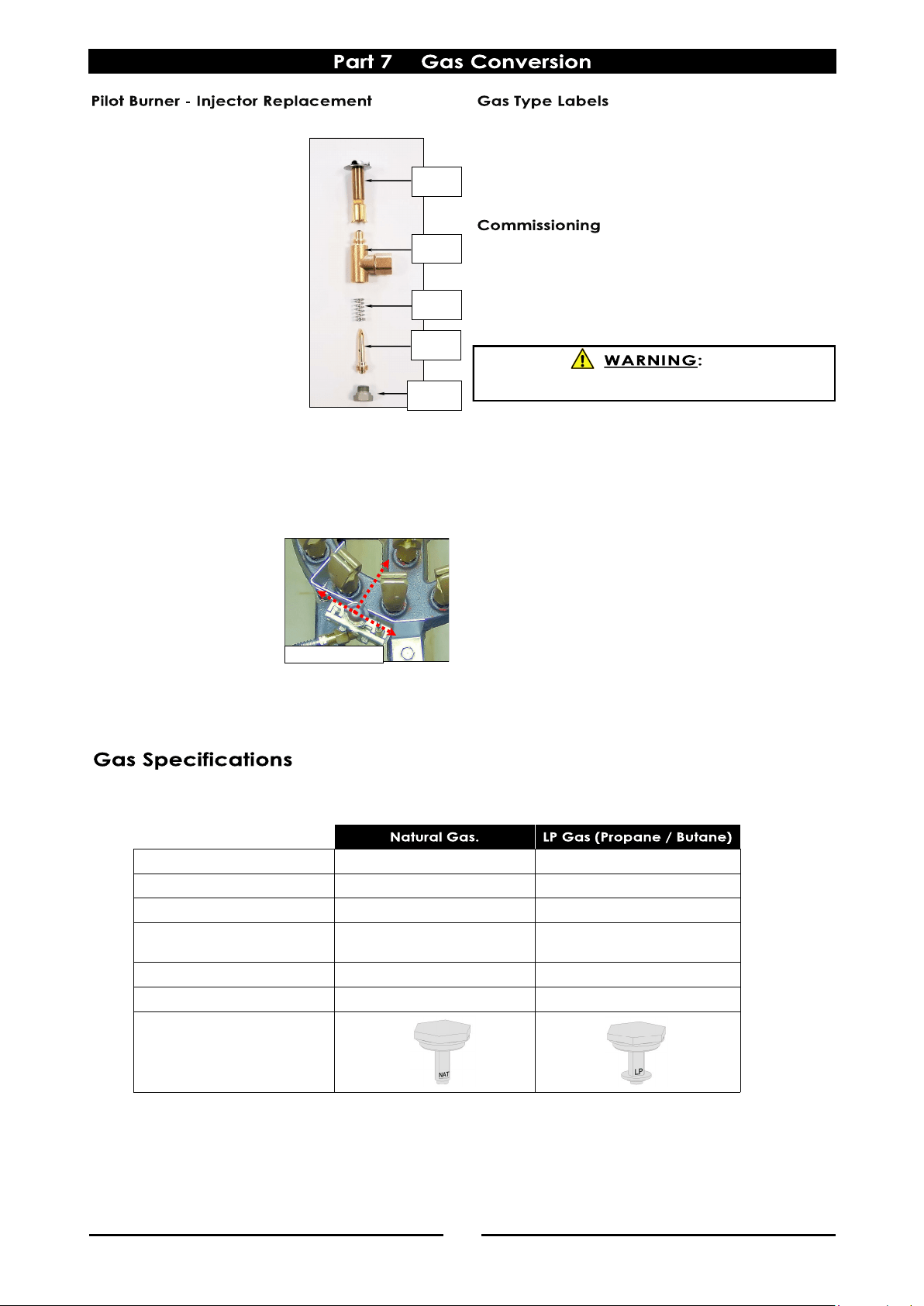

1. Unscrew and remove the

blanking screw at base of

the pilot burner assembly.

2. Remove the pilot injector

and spring, taking care not

to lose the spring.

3. Fit the spring to the

replacement pilot injector

and using a small flat

bladed screwdriver, screw

the pilot injector fully home.

4. Light the pilot burner and

ensure the flame is the

correct size.

5. Turn ‘Off’ pilot burner and

refit the blanking screw to

the base of the pilot

assembly.

6. On completion, refit the Pilot Shield to the Pilot

Bracket, (this is a push-fit onto the pilot bracket).

NOTE:

It is critical that when

re-fitting the pilot burner,

the pilot burner is correctly

orientated in the pilot

bracket as shown below so

that the pilot flame strikes

the thermocouple and also

ignites the main burner

otherwise the pilot burner

will not operate correctly.

On completion of gas conversion, replace gas type

labels located at:-

- Rear of unit, above the gas connection.

- Beside the rating plate.

Before leaving the installation;

1. Check all gas connections, including the pilot

burner injector base connection, for leakage

using soapy water or other gas detecting

equipment.

2. Carry out a ‘Commissioning’ check of the

appliance as shown in Installation Section of this

manual.

3. Ensure any adjustments done to components

that have adjustments / settings paint sealed,

these are to be re-sealed.

NOTE: If it is not possible to get the appliance to

operate correctly, shut ‘Off’ gas supply and

contact supplier of this appliance.

DO NOT USE A NAKED FLAME TO CHECK FOR GAS LEAKAGES.

Pilot

Burner

Pilot

Injector

Blanking

Screw

Injector

Spring

Injector

Body

Duckbill Burner

Loading ...

Loading ...

Loading ...