Loading ...

Loading ...

Loading ...

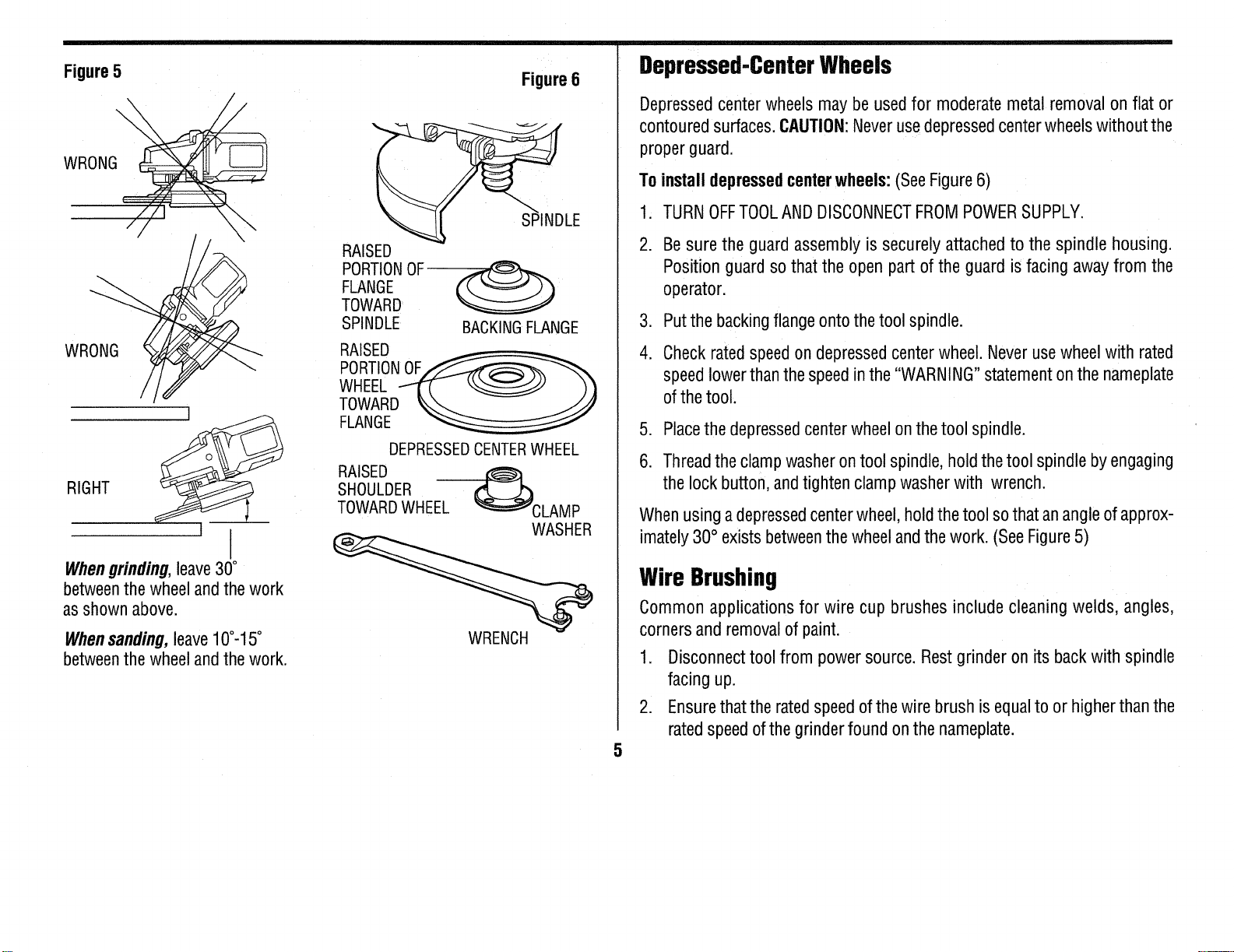

Figure5 Figure6

%

WRONG

WRONG

I

RIGHT ,_

I

Whengrinding,leave30°

betweenthe wheeland the work

as shown above.

Whensanding,leave10°-15°

betweenthe wheeland the work.

RAISED

PORTIONOF _

FLANGE

TOWARD

SPINDLE BACKINGFLANGE

RAISED

PORTIONOF_

WHEEL _ _ ) _t

TOWARD _,,_ J..,j_

FLANGE

DEPRESSEDCENTERWHEEL

RAISED

SHOULDER

TOWARDWHEEL CLAMP

WASHER

WRENCH

Depressed-CenterWheels

Depressedcenter wheels may be used for moderate metal removal on flat or

contoured surfaces.CAUTION:Neverusedepressedcenterwheelswithout the

properguard.

Toinstall depressedcenterwheels:(SeeFigure6)

1 TURN OFFTOOLANDDISCONNECTFROMPOWERSUPPLY.

.

,

4.

Besure the guard assembly is securely attached to the spindle housing.

Position guard so that the open part of the guard is facing awayfrom the

operator.

Putthe backingflangeonto the tool spindle.

Checkrated speedon depressedcenter wheel. Neverusewheel with rated

speedlower thanthe speedinthe "WARNING"statement onthe nameplate

ofthe tool.

5. Placethe depressedcenter wheelonthe tool spindle.

6. Threadthe clamp washerontool spindle, holdthe tool spindle by engaging

the lock button, and tighten clamp washer with wrench.

Whenusing adepressedcenterwheel,hold thetool sothat anangleof approx-

imately 30° exists betweenthe wheeland the work. (SeeFigure5)

WireBrushing

Common applications for wire cup brushes include cleaning welds, angles,

corners and removal of paint.

1. Disconnect tool from power source. Rest grinder on its back with spindle

facing up.

2. Ensurethat the ratedspeedof thewire brush is equalto or higher than the

rated speedofthe grinder found on the nameplate.

Loading ...

Loading ...

Loading ...