Loading ...

Loading ...

Loading ...

–

9

–

6.2 GRINDING

When performing grinding operations maintain an angle of

approximately 30° between the work surface and the disc

face.

Only use abrasives specically designed for this task.

Warning!

Important legal information:

– Cutting operations should only be attempted with the

“cutting” guard tted to this grinder.

– Please contact Draper Tools for further information on

how to purchase this optional accessory.

– This guard must be tted for your safety.

– When performing cutting-off operations do not incline

the machine as this can lead to the abrasive wheel

becoming jammed, damaged or excessively and

abnormally worn.

– Only use abrasives specically designed for this task.

Warning: As the abrasive wheel wears during use, its

diameter reduces. This reduces the peripheral speed and

the machine’s efciency. This results in increased load on

the grinding machine which if continued will damage the

motor. Ensure that the diameter of the wheel is within 25%

of its original size.

Important: Excessive pressure on the machine does not

result in a higher abrasive efciency. Excessive pressure

increases wear and tear on the accessory and will damage

the angle grinder which is not covered under the warranty.

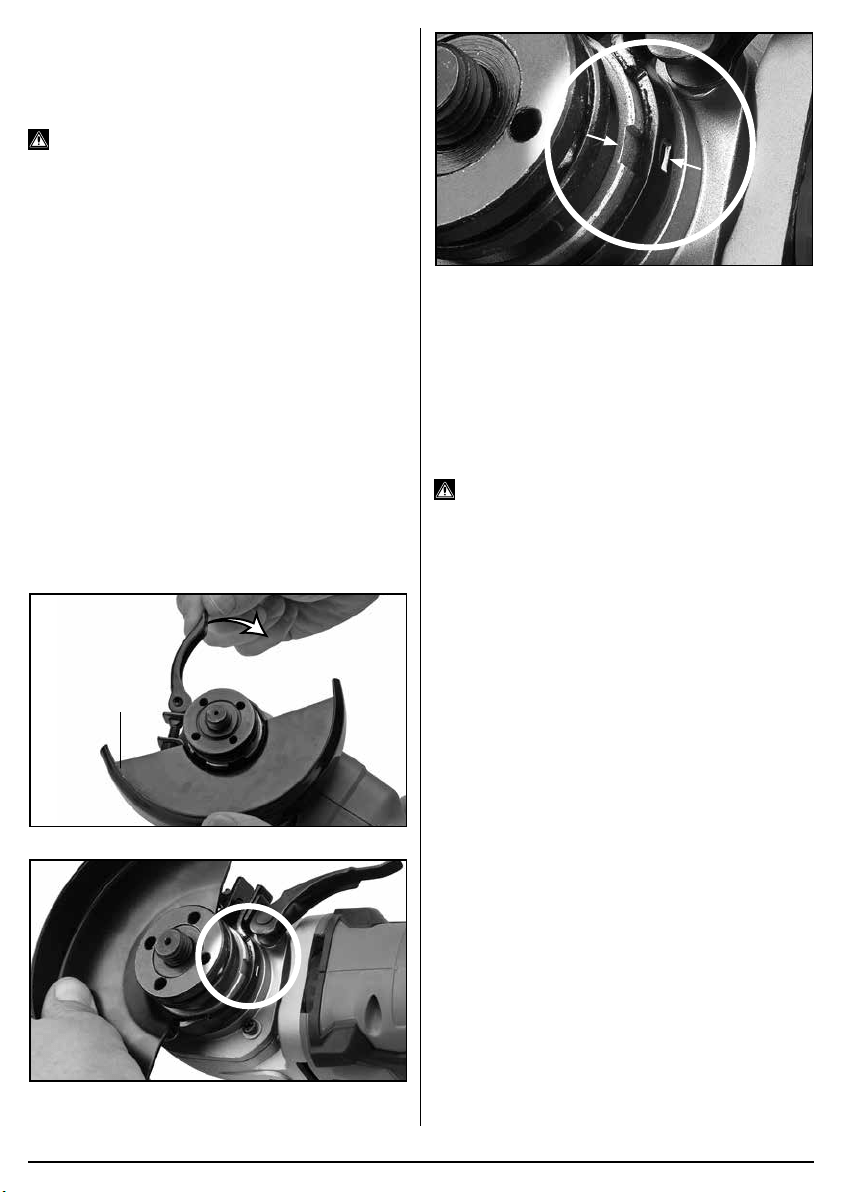

6.3 FITTING THE GUARD - FIGS. 2–4

2

FIG.

(6)

3

FIG.

4

FIG.

To t:

Position the guard (6) onto the grinder collar with the

quick release lever open.

Rotate the guard until the spigot lines up with the cutout,

once located the guard can be rotated to the working

position and tightened.

To remove:

Open quick release lever, rotate the guard until the spigot

lines up with the cutout, and remove.

Warning!

Never attempt to operate this machine

without the guard securely tted and correctly positioned*.

* With the exception of wire cup brushes etc. which

negate the guards effectiveness.

6.4 FITTING/REPLACING

ACCESSORIES (sold separately)

– FIG. 5

Warning! Prior to mounting an abrasive wheel ensure

the expiry date has not expired, rendering it potentially

hazardous.

Warning! Selection of the correct accessory, suitable for

the intended application is vital. Seek guidance if

uncertain of selection.

Warning! The rated (no load) revolutions per minute of

the tool must not exceed the speed capacity of the

accessory. Please refer to the accessory manufacturers

instructions for information.

Visual Inspection:

– Prior to tting, abrasive/superabrasive wheels shall

be subject to a visual inspection.

Inspection:

– Each time after mounting, the abrasive/

superabrasive wheel shall be test run for a

reasonable time.

– The specied maximum operating speed of the

wheel shall not be exceeded.

– Damaged abrasives shall be destroyed.

– Always wear approved safety goggles.

Loading ...

Loading ...

Loading ...