Loading ...

Loading ...

Loading ...

:wARN!NG

Always stopengine,

disconnectspark

plug,andground

againstenginebefore

cleaning,lubricating

or doing any kindof

maintenanceonyour

machine!

if unit istipped for

easieraccessto

bladeorbeltltip

mowerasspecified

inseparateengine

manual,if itdoesnot

specifyturnmower

on its side making

sure that the air filter

and the carburetor

cuttinggrassin

sandy soil Condition

causes abrasive wear

to the bladei

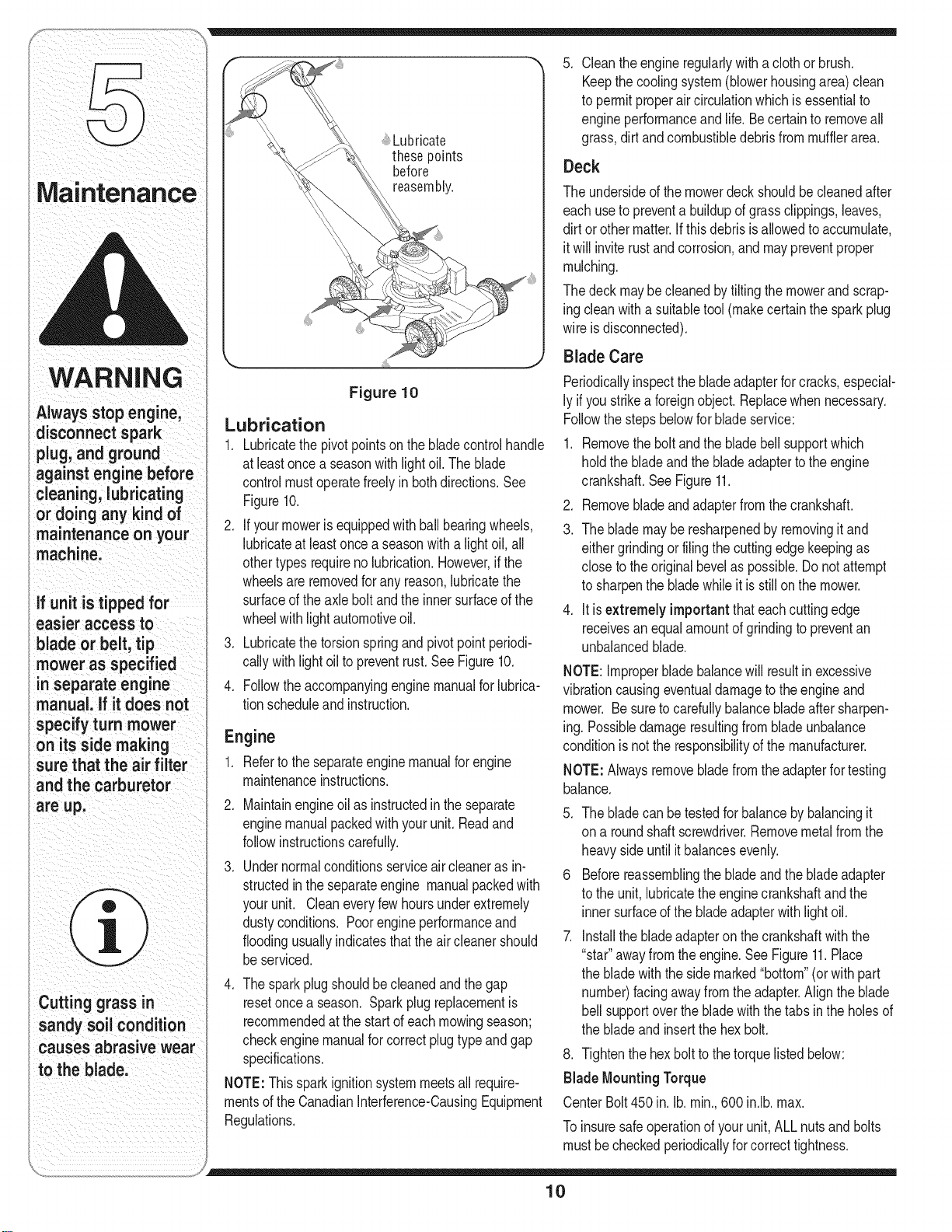

Lubricate

thesepoints

before

reasembly.

Figure 10

Lubrication

1. Lubricatethepivotpointsonthebladecontrolhandle

atleastoncea seasonwithlightoil.Theblade

controlmustoperatefreelyin bothdirections.See

Figure10.

2. If yourmowerisequippedwithballbearingwheels,

lubricateat leastoncea seasonwitha lightoil,all

othertypesrequireno lubrication.However,ifthe

wheelsareremovedforanyreason,lubricatethe

surfaceoftheaxleboltandtheinnersurfaceofthe

wheelwithlightautomotiveoil.

3. Lubricatethetorsionspringandpivotpointperiodi-

callywithlightoil topreventrust.SeeFigure10.

4. Followtheaccompanyingenginemanualforlubrica-

tionscheduleandinstruction.

.

2.

Engine

Refertotheseparateenginemanualforengine

maintenanceinstructions.

.

Maintainengineoil asinstructedin theseparate

enginemanualpackedwithyourunit. Readand

followinstructionscarefully.

Undernormalconditionsserviceaircleanerasin-

structedintheseparateengine manualpackedwith

yourunit. Cleaneveryfewhoursunderextremely

dustyconditions. Poorengineperformanceand

floodingusuallyindicatesthattheaircleanershould

be serviced.

4. Thesparkplugshouldbecleanedandthegap

resetoncea season.Sparkplugreplacementis

recommendedatthestartof eachmowingseason;

checkenginemanualforcorrectplugtypeandgap

specifications.

NOTE:Thissparkignitionsystemmeetsall require-

mentsof theCanadianInterference-CausingEquipment

Regulations.

.

Cleantheengineregularlywithaclothor brush.

Keepthecoolingsystem(blowerhousingarea)clean

topermitproperair circulationwhichisessentialto

engineperformanceandlife.Becertaintoremoveall

grass,dirtandcombustibledebrisfrommufflerarea.

Deck

Theundersideofthemowerdeckshouldbecleanedafter

eachuseto preventa buildupofgrassclippings,leaves,

dirtorothermatter.If thisdebrisisallowedtoaccumulate,

itwillinviterustandcorrosion,and maypreventproper

mulching.

Thedeckmaybecleanedbytiltingthemowerandscrap-

ingcleanwitha suitabletool(makecertainthesparkplug

wireisdisconnected).

Blade Care

Periodicallyinspectthebladeadapterforcracks,especial-

lyifyoustrikea foreignobject.Replacewhennecessary.

Followthestepsbelowforbladeservice:

1. Removetheboltandthebladebellsupportwhich

holdthebladeandthebladeadaptertotheengine

crankshaft.SeeFigure11.

2. Removebladeandadapterfromthecrankshaft.

3. Theblademayberesharpenedbyremovingitand

eithergrindingorfilingthecuttingedgekeepingas

closetotheoriginalbevelaspossible.Donotattempt

tosharpenthebladewhileitisstill onthemower.

4. it isextremely important thateachcuttingedge

receivesanequalamountof grindingto preventan

unbalancedblade.

NOTE:improperbladebalancewillresultin excessive

vibrationcausingeventualdamagetotheengineand

mower.Besuretocarefullybalancebladeafter sharpen-

ing.Possibledamageresultingfrombladeunbalance

conditionisnotthe responsibilityofthemanufacturer.

NOTE:Alwaysremovebladefromtheadapterfortesting

balance.

5. Thebladecanbetestedforbalancebybalancingit

ona roundshaftscrewdriver.Removemetalfromthe

heavysideuntilit balancesevenly.

6 Beforereassemblingthebladeandthebladeadapter

totheunit,lubricatetheenginecrankshaftandthe

innersurfaceofthebladeadapterwithlightoil.

7. Installthebladeadapteron thecrankshaftwiththe

"star"awayfromtheengine.SeeFigure11.Place

thebladewiththesidemarked"bottom"(orwithpart

number)facingawayfromtheadapter.Aligntheblade

bellsupportoverthebladewiththetabsin theholesof

thebladeandinsertthehexbolt.

8. Tightenthehexbolttothetorquelistedbelow:

Blade Mounting Torque

CenterBolt450 in.lb.rain.,600 in.lb,max.

Toinsuresafeoperationofyourunit,ALLnutsand bolts

mustbecheckedperiodicallyforcorrecttightness.

10

Loading ...

Loading ...

Loading ...