Loading ...

Loading ...

Loading ...

27

27

Gas checks and adjustments - pressure adjustment

First shut off the gas to the oven. Remove the sealing screw from the

regulator test point at the rear of the oven and attach the hose from the

mamometer to the point. Turn the gas back on and light the burner on the

maximum temperature setting. Check the pressure and adjust at the

regulator if necessary to reach the settings in the table or on the data

plate. For LPG adjust at the regulator at the cylinder.

Turn regulator adjusting screw clockwise to increase pressure and anti

clockwise to reduce pressure. Refit the test point sealing screw when

finished.

1.

The oven must not be lifted using the door handle.

Gas Conversion

If the oven is to be used with another gas type, either Propane Gas or

Natural Gas, it must be converted by an Authorised Person. The table in

this manual shows the appropriate injector sizes for either Propane Gas or

Natural Gas.

IMPORTANT NOTES

THE INSTALLATION IS THE RESPONSIBILITY OF THE PURCHASER

AND ANY INTERVENTIONS REQUESTED FROM THE MANUFACTURER

DUE TO INCORRECT INSTALLATION ARE NOT COVERED BY THE

WARRANTY.

Upon completion of the installation, the qualified technician MUST ISSUE

A DECLARATION OF CONFORMITY OF THE WORK PERFORMED.

The above mentioned technician is responsible for any damage to persons

or objects caused by connections which do not conform to regulations.

2.

The oven must be serviced and checked every 3 to 4 years

depending on usage and condition.

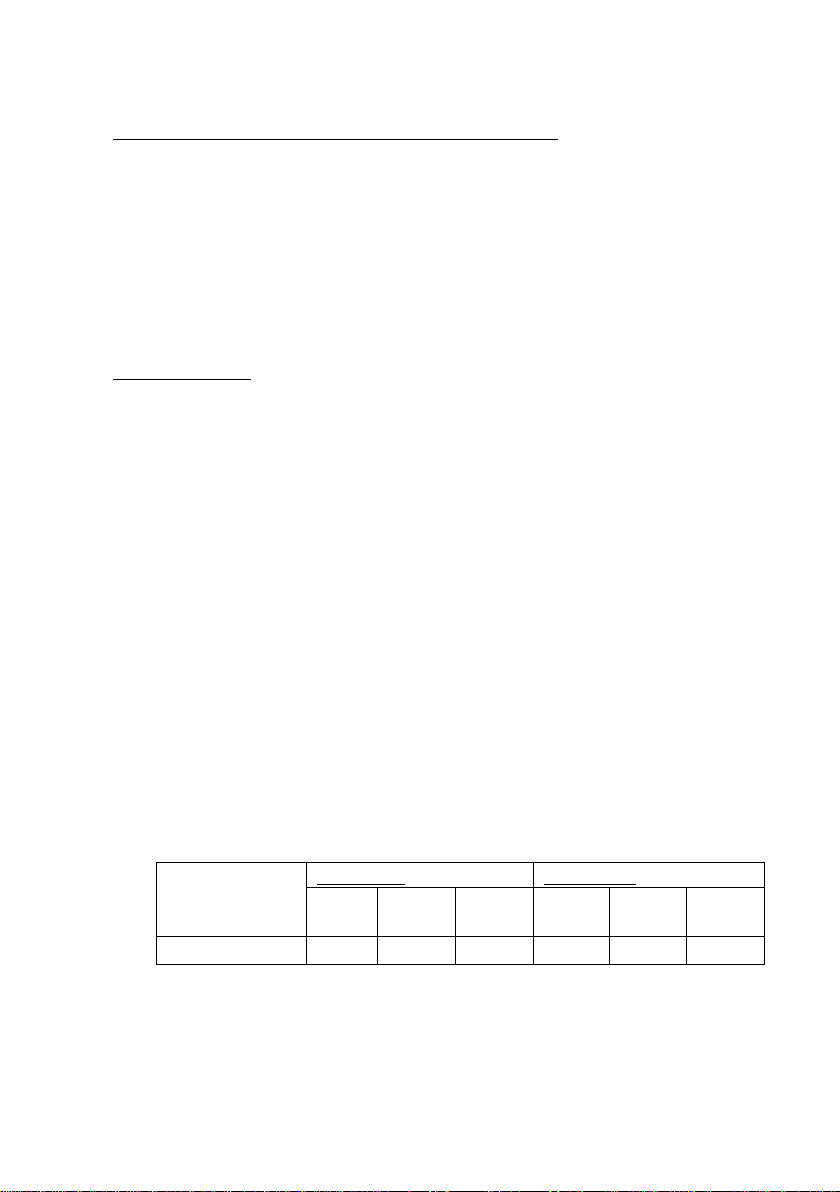

TECHNICAL DATA - Injector specification

NATURAL PROPANE

Inj

Diam

MJ/H Gas

Press

Inj

Diam

MJ/H Gas

Press

Oven Burner 1.23 7.5 1.0 0.79 8.5 2.75

Loading ...

Loading ...

Loading ...