Loading ...

Loading ...

Undernormal conditiotas, best results will be ob-

tained by using a 1/3 horsepower 1750 R.P,M.

motor. For continuous heavy duty work, a _ horse-

_ower motor of the same speed is recommended. By

Mng a four step motor pulley the same size as the

spindle pulley, the following recommended speeds

may be ffhtained.

Work Diameter R.P,M, Roughing R.P.M. F_rli_hiag

Up to 2" 2325 3450

2" to 3" I325 2250

3" to 5" 825 1350

5" to 9" 825 875

The following table shows the diameter of the

pulley step in which the belt should be placed

in order to obtain the desired speed in Revo-

lutions Per Minute.

Latl_€ Pulley Motor Pulley

R,P.M. Step Dis. Step Dis.

3450 2" 4"

22.50 2_"

875 4" 2"

The four step motor pulley mentioned may be

obtained from your Sears retail store or mail order

house. Be sure to specify the shaft diameter of your

motor when ordering this pulley,

¢ONTROLS_ See Hgure I

TAILSTOCK lOCK:

Major adjustment of distance between centers may

be made by loosening the tailatock lock allowing

the operator to move the tailstock along the tubular

bed to a desired position. The tailstock 10ck must

be securely tightened before the work is under

power.

HANDWHEEL:

Minor adjustments of distance between centers are

made by turning the handwheel thus moving the

cup center toward or away from the work piece as

desired.

TAILSTOCK RAM LOCK:

As its name indicates, the ram lock holds the ram

in a fixed position so that it will not move and

loosen its grip on the work piece as a result of vibra-

tion. The tailstoekram must be locked securelyin

poaltion during cutting operations on work between

centers,

TO01. Sk|D| LOCK (:LAMP HANOLIs

Loosen the slide lock handle to change the angle

of the tool _st holder or to change its position on

the tubular bed, After the desired adjustment has

been made re-tighten the handle,

TOOL REST LOCKt

Tool rest is fully adjustable for any turning opera-

lion, It is held ,ecurely by the tool rest lock.

INDIX|NG PINI

:::'The.indcs2ng pin is in line with a series of,_6

equally apBced holes in the surface of the step puney

inside the headstock. This spring loaded pin, when

3

allowed to project through the casting and into a

hole in the pulley, locks the entire turning assembly

attached to the spindle.

Through the use of this pin, the spindle may be

held stationary for various operations such as laying

out patterns and centerlines on face plate work. The

index pin provides a means of spacing the various

cuts in fluting and feeding operations,

Do not use indexing pin for attaching or remov_

of f_ace plates. A drilled hole in the headstock

spindle collar is provided to remove face plates, An

Allen wrench, large nail, or any similar item, ap-

proximately the same size as the hole, can be inserted

and revolved until it bears against the indexing

plunger. This will lock the spindle and a_low the

face plate to be unscrewed.

With the index pin engaged, the latb, e may be

used as a fixture for holding long twist or spiral work

for the hand finishing operations, it is always a good

policy to double check all control units before ap-

plying power with a job set up in the lathe, q_e

operator should be sure that the tailstock and the

tailstock ram are securely locked, that the tool rest

and toot rest holder are held rigidly in position, that

the belt is in the right pulley groove for the speed

desired, and finally that the index pin is retracted

and clear of the pulley.

The set screw, No. 30, in the tailstock should be

checked occasionally to assure the proper pressure

against the key and to keep taitstock at 90 _'_to the

tubular'bed.

"-_!t

Sk,e_

!

k

P¢h_t

Roland

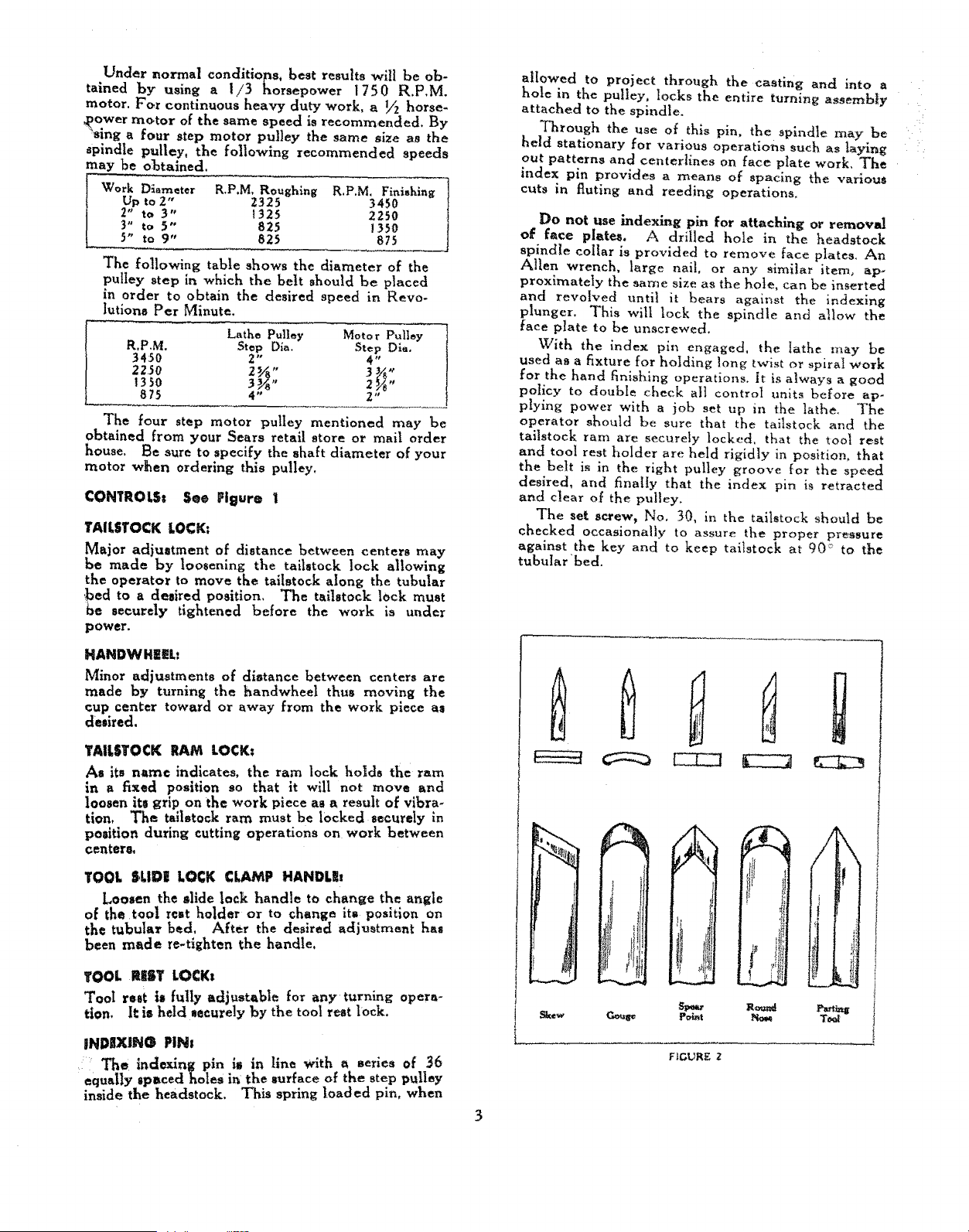

FIGURE 2

Loading ...

Loading ...

Loading ...