Loading ...

!ii:i! OPERATi N€

AND PART5

REST

TOOL SLIDECLAMP

LOCK

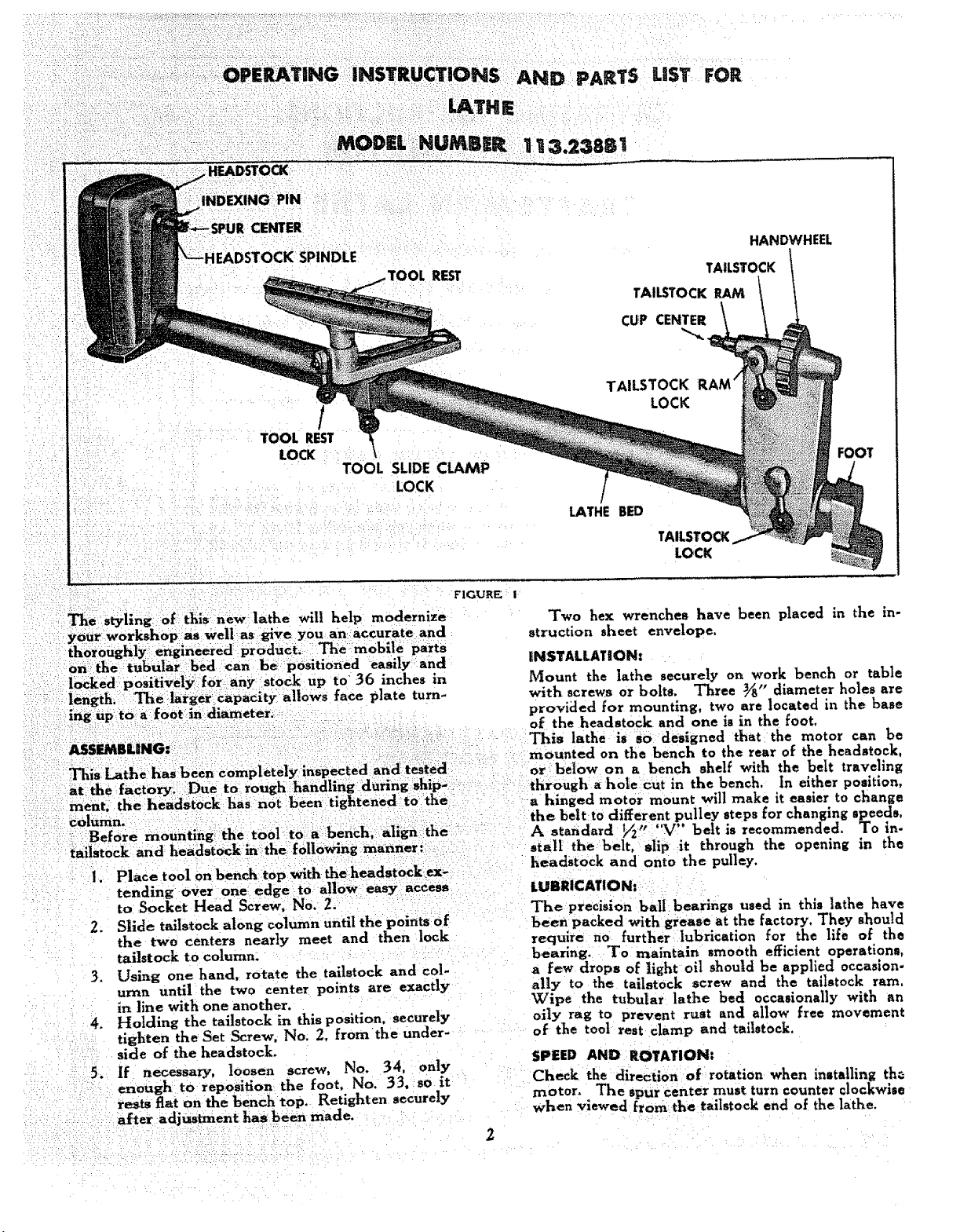

HEADSTOCK

i.DEXING

CENTER

)STOCK SPINDLE

!

TOOL REST

LOCK

• i_:: :

. The Styling of _is new lathe will help modernize

yourworkshop as well- as give you an: accurate and

:The mobile pa_ts

on _the :tubular bed can be positioned easily and

..... locked positively for any Stock up to 36 inches in

length_ Thelargercapacity allows face plate turn-

ing Upton foot ind_eter, _........ :

FIGURE I

Place tool on bench top _vith the_headstock_ex-

tending over oneledge to allow easy access

to Socket Head Screw, No. 2.

Slide tailstock along column until the points of

the two centers nearly meet and then lock

tailstock to column:

Using one hand, rotate the tailstock and col-

umn until the two center points are exactly

in line with one another.

Holding the tailstock in this position, securely

tighten the Set Screw, No. 2, fromthe under-

side of the headstock.

If necessary, loosen screw, No. 34, only

enough to reposition the foot, No. 33, so it:

rests flat on the bench top. Retighten securely

after adjustment has been made.

LATHE BED

LRST FOR

HANDWHEEL

TAILSTOCK

TAILSTOCK RAM

CUP CENTER

TAILSTOCK

LOCK

,

,

,

.

FOOT

TAILSTOCK

LOCK

Two hex wrenches have been placed in the in-

struction sheet envelope.

|NSTALLATIONz

Mount the lathe securely on work bench or table

with screws or bolts, Three _" diameter holes are

provided for mounting, two are located in the base

oE the headstock and one is in the foot,

-This lathe is so designed that the motor can be

mounted on the bench to the rear of the headstock,

or below on a bench shelf with the belt traveling

through a ho|e cut in the bench. In either position,

-a hinged motor mount will make it easier to change

the beltto different pulley steps Eor changing speeds,

A standard _" "V" belt is recommended, To in-

stall the belt, slip it through the opening in the

headstock and onto the pulley.

LUBRICATION:

The precision ball bearings used in this lathe have

been packed with grease at the factory. They should

require no further lubrication for the life of the

bearing. To maintain smooth efficient operations,

a few drops of light oil should be applied 0cession-

ally to the tailstock screw and the tailstock ram,

V_/ipe the tubular lathe bed occasionally with an

oily rag to prevent rust and allow free movement

of the tool rest clamp and tailstock.

SPEED AND ROTATION:

Check the direction of rotation when installing th_

motor. The spur Center must turn counter clockwise

when viewed from the tailstock end of the lathe.

Loading ...

Loading ...

Loading ...