Loading ...

Loading ...

Loading ...

12

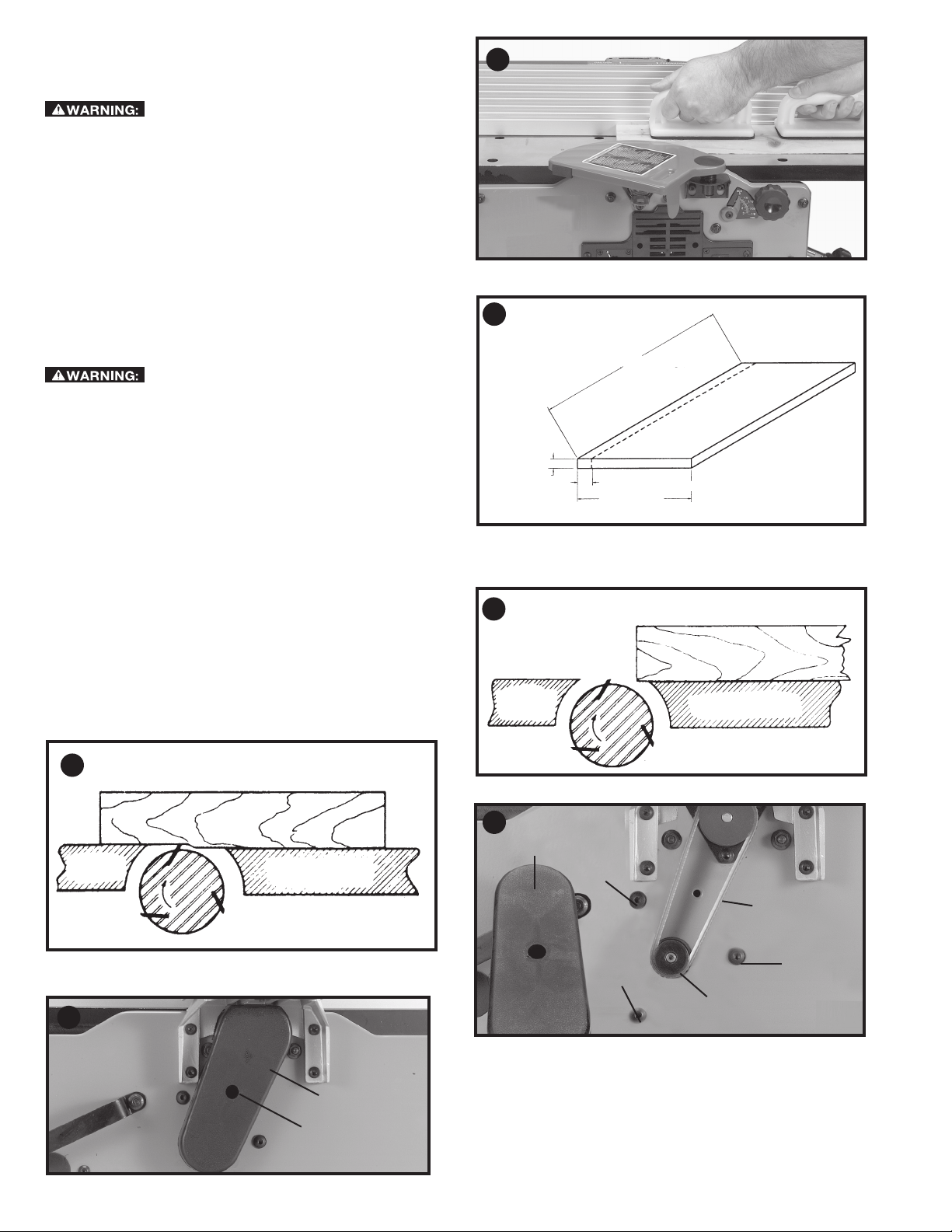

PLANING SHORT OR THIN WORK

When planing short or thin pieces, always use push blocks to

minimize all danger to the hands. Fig. 40, illustrates using the

Push Blocks properly.

Do not perform jointing operations on

material shorter than 10 inches (254 mm), narrower than

3/4 inch (19 mm), or less than 1/2 inch (12.7 mm) thick (refer

to Fig. 41).

DIRECTION OF GRAIN

Avoid feeding work into the jointer against the grain as shown

in Fig. 42. The result will be chipped and splintered edges. Feed

with the grain as shown in Fig. 43 to obtain a smooth surface.

TROUBLESHOOTING

For assistance with your machine, visit our website at www.

portercable.com for a list of service centers or call the help line

at 1-888-848-5175.

MAINTENANCE

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

BELT REPLACEMENT

When it becomes necessary to replace the belt on your jointer:

1. Remove screw (A) Fig. 44, using hex wrench supplied, and

remove belt guard (B).

2. Loosen three screws (C) Fig. 45, to release belt tension

and remove belt (D) from pulleys.

3. Assemble new belt to the cutterhead and motor pulleys.

Press down on motor pulley (E) Fig. 45, to tension belt and

tighten three screws (C).

NOTE: There should be approximately 1/4 inch (6.4 mm)

deflection in the belt (D) at the center span of the pulleys

using light finger pressure. The belt does not require excessive

tension to function properly.

4. Replace belt guard (B) Fig. 44.

MINIMUM AND

MAXIMUM PLANING

DIMENSIONS

1/2 inch

(12.7 mm)

MINIMUM

3/4 inch (19mm) MINIMUM

6 inches

(152.4 mm) MAXIMUM

10 inches (254 mm) MINIMUM

IN-FEED TABLE

OUT-FEED

TABLE

CUTTER

WRONG FEED -

AGAINST THE

GRAIN

MATERIAL

B

A

B

C

C

C

D

E

41

44

42

40

45

IN-FEED TA BLE

OUT-FEED

TABLE

CUTTER

MATERIAL

43

CORRECT FEED - WITH THE GRAIN

Loading ...

Loading ...

Loading ...