Loading ...

Loading ...

Loading ...

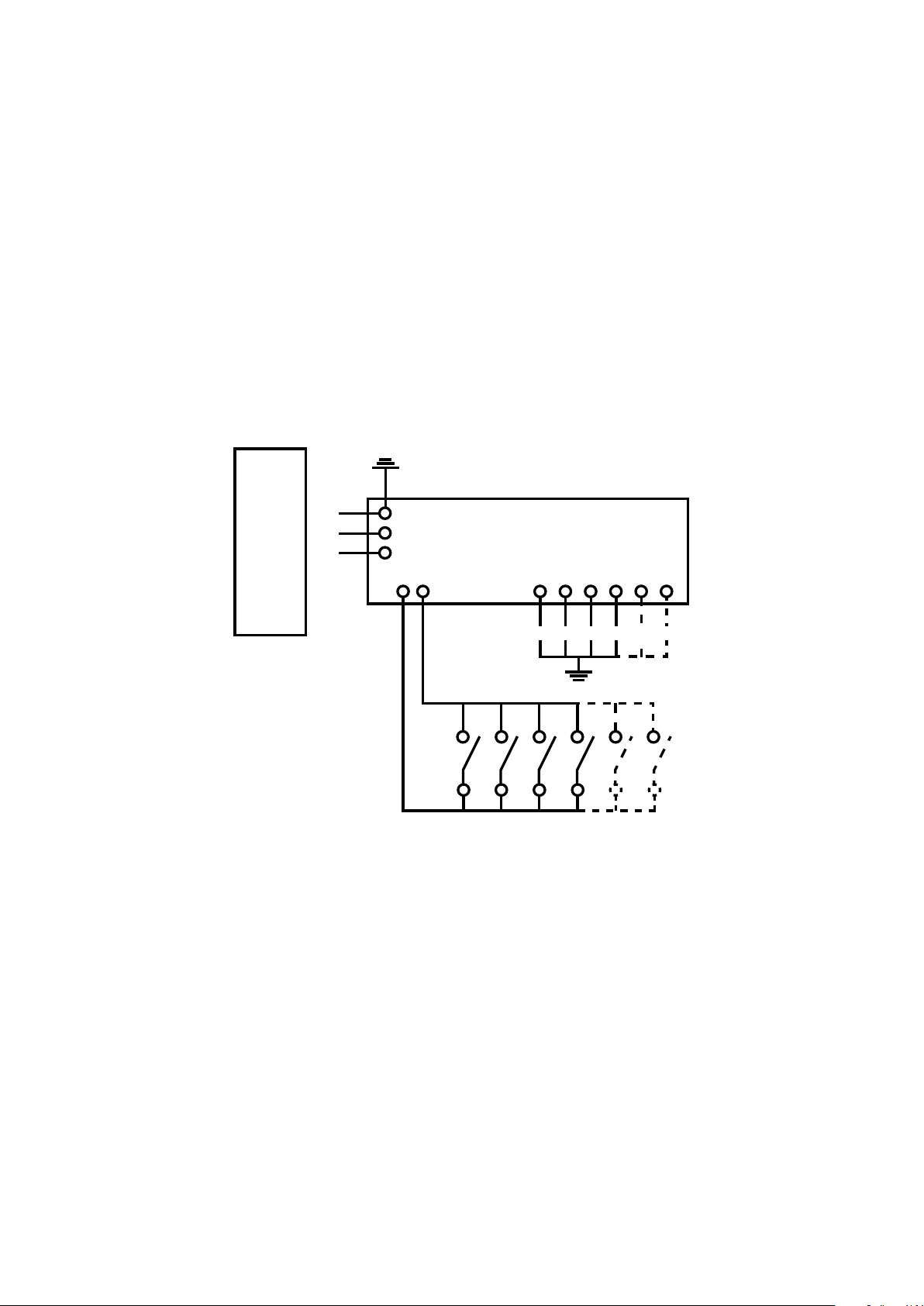

24 25

Diagram 1

DANGER

220-240 VOLTS AC

DISCONNECT FROM SUPPLY

BEFORE REMOVING PANEL

220-240V

IGNITION

BOX

BODY

E

N

L

KNOB

IGNITION

SWITCHES

TO BURNER SPARK PLUGS

The appliance is supplied with a standard 7.5 Amp service

cord terminated by a 3-pin plug for connection to a standard

household socket. The electrical supply is required to power

the electronic ignition system.

NOTE! It will be necessary for servicing purposes to

disconnect the electrical power supply. The power

point should therefore be accessible after the appliance

is installed, as specified in the local wiring regulations.

Diagram 1 is a schematic of the wiring in the appliance.

WEIGHT of the unit is printed on the appliance

packaging label.

ELECTRICAL CONNECTION (220-240 VOLTS)

After installation, test the appliance and ensure that it

operates correctly before handing it over to the customer.

The following procedure is recommended:

1. Turn on the gas and electricity supply and attempt

ignition on all burners, both separately and in

combination. (For correct procedure refer to page

9 Lighting Burners). Note that additional time needs

to be allowed for the initial lighting as air has to be

purged from the pipes.

2. Observe the flame appearance on each burner

(Figure 9). If it is much larger or much smaller than

expected, the injector size and supply pressure

require checking. Where a flame is unsatisfactory,

refer to the Troubleshooting Guide (page 12) to

correct the fault. If the Troubleshooting Guide does

not solve the problem, call the Service Centre.

3. When all the foregoing is satisfactory, check the

turndown (minimum or low) setting on each burner,

as this may need adjustment. Valves have a bypass

controlling screw, which may be accessed by

removing the knob. This screw will be located on a

particular area of the valve (refer Figure 10). Normally,

this will have been correctly set at the factory for

use on Natural Gas (NG) and should not require

adjustment.

IMPORTANT

If the appliance has been converted to LPG, then

the bypass screw will HAVE to be screwed in until a

small, stable flame results.

Please ensure the supply pressure has been

checked PRIOR to any adjustment.

4. If the appliance cannot be adjusted to perform safely

inform the customer of the problem and affix an

appropriate warning notice to the appliance. If the

fault appears to be dangerous the appliance should

be disconnected. If a minor fault exists, the customer

may wish to use the appliance while awaiting service.

If a fault cannot be fixed, please call the

Service Centre.

5. The customer should be advised that, in the event

of a fault, the local service organisation or the

retailer from whom the appliance was purchased

should be contacted.

6. When satisfied that the unit is operating correctly,

turn off and instruct the customer on correct

operation as outlined in this booklet. Ask the

customer to operate the controls to ensure that

the correct procedure is understood.

TESTING APPLIANCE OPERATION

CAUTION

Servicing must only be carried out by an authorised

service person.

Injector sizes required for various gas types are shown in

Table 3 (page 22). The appliance test point pressure for each

gas type is also shown.

For model identification after installation, an additional data

plate sticker has been provided. This sticker is to be stuck

onto adjacent cabinetry.

flame size adjusted to maximum

bypass screw

Figure 9

Figure 10

flame size adjusted to minimum

Loading ...

Loading ...

Loading ...