Loading ...

Loading ...

Loading ...

26 - English

NOTE: New chains tend to stretch; check the

chain tension frequently and adjust as needed.

NOTICE:

A chain tensioned while warm may be too tight

upon cooling. Check the “cold tension” before

next use.

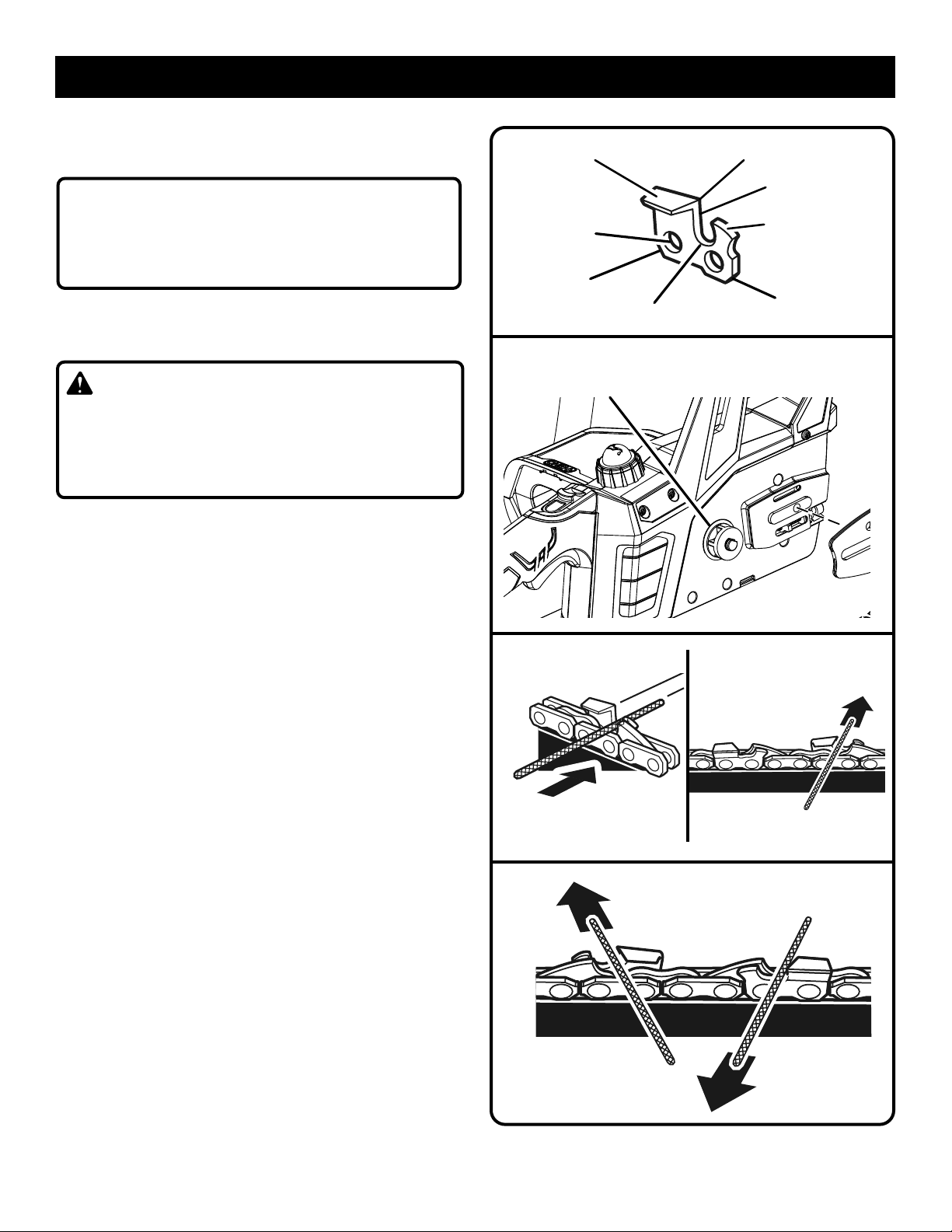

CHAIN MAINTENANCE

See Figures 31 - 32.

WARNING:

Remove the battery pack and make sure the

chain has stopped before you do any work on

the saw to avoid accidental starting and pos-

sible serious personal injury.

Use only low-kickback chain on this saw. This

fast-cutting chain will provide kickback reduction

when properly maintained.

For smooth and fast cutting, chain needs to be

maintained properly. The chain requires sharpen-

ing when the wood chips are small and powdery,

the chain must be forced through the wood dur-

ing cutting, or the chain cuts to one side. During

maintenance of your chain, consider the following:

Improper filing angle of the side plate can

increase the risk of a severe kickback.

Raker (depth gauge) clearance.

Too low increases the potential for kickback.

Not low enough decreases cutting ability.

If cutter teeth have hit hard objects such as nails

and stones, or have been abraded by mud or

sand on the wood, have service dealer sharpen

chain.

NOTE: Inspect the drive sprocket for wear or dam-

age when replacing the chain. If signs of wear or

damage are present in the areas indicated, have

the drive sprocket replaced by a RYOBI Service

dealer.

HOW TO SHARPEN THE CUTTERS

See Figures 33 - 34.

Be careful to file all cutters to the specified angles

and to the same length, as fast cutting can be

obtained only when all cutters are uniform.

MAINTENANCE

Fig. 33

LEFT HAND

CUTTERS

RIGHT HAND

CUTTERS

Fig. 34

CHECK FOR WEAR

OR DAMAGE

Fig. 32

Fig. 31

CUTTING CORNER

SIDE PLATE

DEPTH GAUGE

TOE

GULLET

HEEL

RIVET HOLE

TOP PLATE

Loading ...

Loading ...

Loading ...