Loading ...

Loading ...

Loading ...

13

Sanding Tips

Aluminum oxide, silicon carbide, or other synthetic abrasives are recommended for power

sanding use. Natural abrasives, such as int or garnet sheets, are too soft for economical use

in power sanding. The uniform spacing between grains minimizes lling or loading. The

high-quality aluminum oxide sheet with heavy backing, sands faster and lasts longer.

Some applications, such as plastics, glass, or stone, require silicon carbide discs, which have

a very sharp cutting edge.

For best results, use sanding accessories that are of superior quality and are carefully select-

ed to produce professional quality results with your sander.

The following are recommended abrasive sheets and applications:

1. Coarse Grit: For rough wood sanding.

2. Medium Grit: For general wood sanding.

3. Fine Grit: For smoothing wood or plaster patches.

4. Extra Fine Grit: For nal sanding bare wood and smoothing old paint.

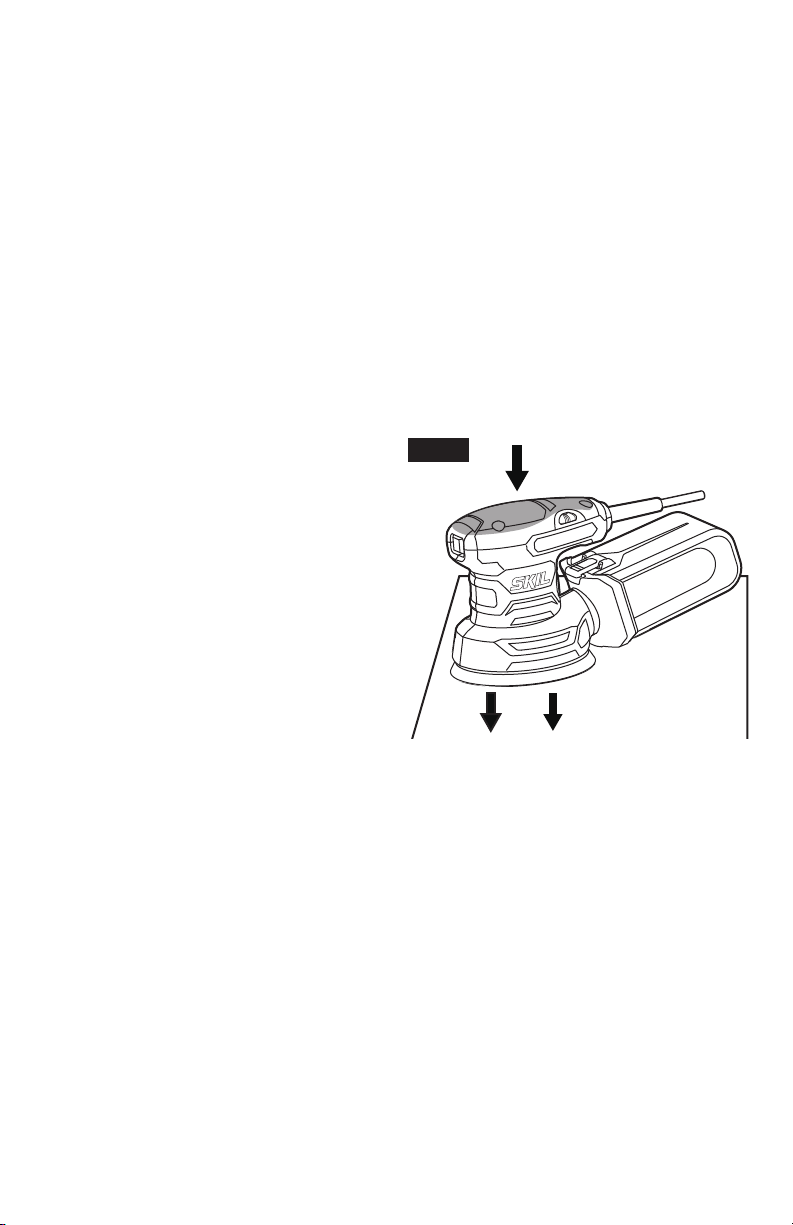

With the workpiece rmly secured, turn the tool

on as described above. Contact the work with

the tool only after the sander has reached its

full, selected speed, and remove it from the

work before switching the tool off. Operating

your sander in this manner will prolong switch

and motor life and greatly increase the quality

of your work.

Move the sander in long, steady strokes par-

allel to the grain, using some lateral motion to

overlap the strokes by as much as 75%. DO

NOT apply excessive pressure — let the tool

do the work. Excessive pressure will result in

poor handling, vibration, and unwanted sand-

ing marks (Fig. 7).

If the surface is rough, begin with coarser grits and then complete the surfacing with medium and

ne abrasives. Because the random orbit action is so effective, it is often possible to begin sand-

ing with a medium grit disc and go directly to ne nishing. To avoid uneven results, do not skip

more than one grit size when going from coarser to ner grits, and do not sand in one area for too

long. When the job is completed, release switch, and gently lift the tool from the work surface at

the same time.

Fig. 7

Loading ...

Loading ...

Loading ...