Loading ...

Loading ...

Loading ...

CUTTtNGWITH A STRAIGHTEDGE (Ftgo14)

1 Mark the pesiIion of the side edge of the

saw base and then clamp the straighledge

on the mark and paraliet to the cut.

2 As you cut, keep the saw base edge Itush

against llle straightedge and ttat on the

workptece

Z_ WARNING: ALWAYS clamp and support workpiece securely, ALWAYS

malnlaln proper control of sew. Failure to clamp and support workplece and

lose of contro! of saw could result in serious Injury.

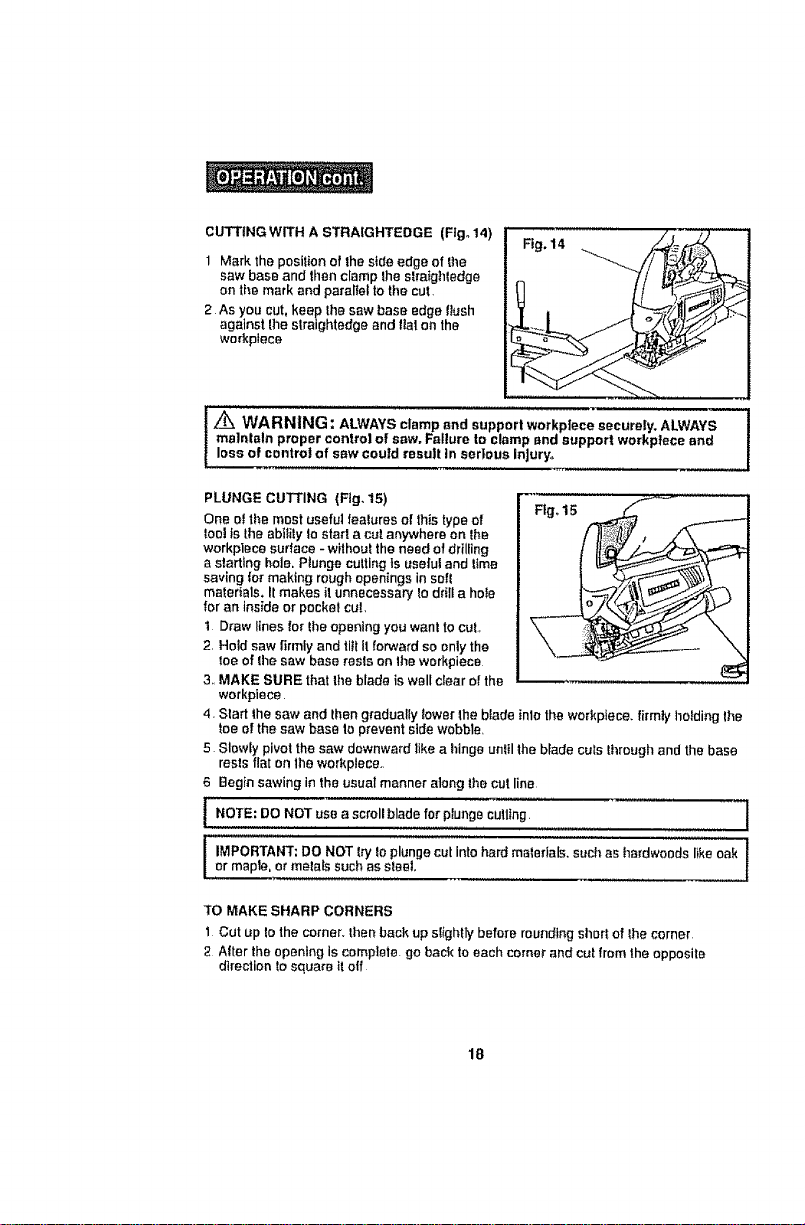

PLUNGE CUTTING (Fig,15)

One of the most useful features of this type of

tool Is the abilify to start a cut anywhere on the

workplace surface -without the need of drilling

a starting hole, Plunge cutting is useful and limb

saving ter making rough openings in soil

materials, It makes it unnecessary to drill a ho_e

for an inside or pocket cut,

t Draw lines for lhe opening you want to cuL

2. Hold saw firmly and fitl It forward so only the

toe of Ille saw base reels on g_eworkplace

3,, MAKE SURE that the blade is well clear o! the

workplace.

4. Slart the saw and then gradually tower the blade into the workplace, firmty holding lhe

tee el'the saw base to prevent side wobble.

5 Slowly pivot the saw downward like a hinge unlII the blade cuts through and tile base

rests flat on lhe workplece..

6 Begin sawing in the usual manner along the cut line.

I NOTE: DO NOT usa a scroll blade for plunge cutting ]

IMPORTANT; DO NOT try lo plunge cut intohard malefials, such as hardwoods like oak 1

or maple, or melats such as sleet.

1

TO MAKE SHARP CORNERS

1 Cut up lo the corner, then back up s_ightly before rounding shor! of the corner

2 Attar the opening is complete, go back to each corner and cut from the opposite

direction to square it elf

18

Loading ...

Loading ...

Loading ...