Loading ...

Loading ...

Loading ...

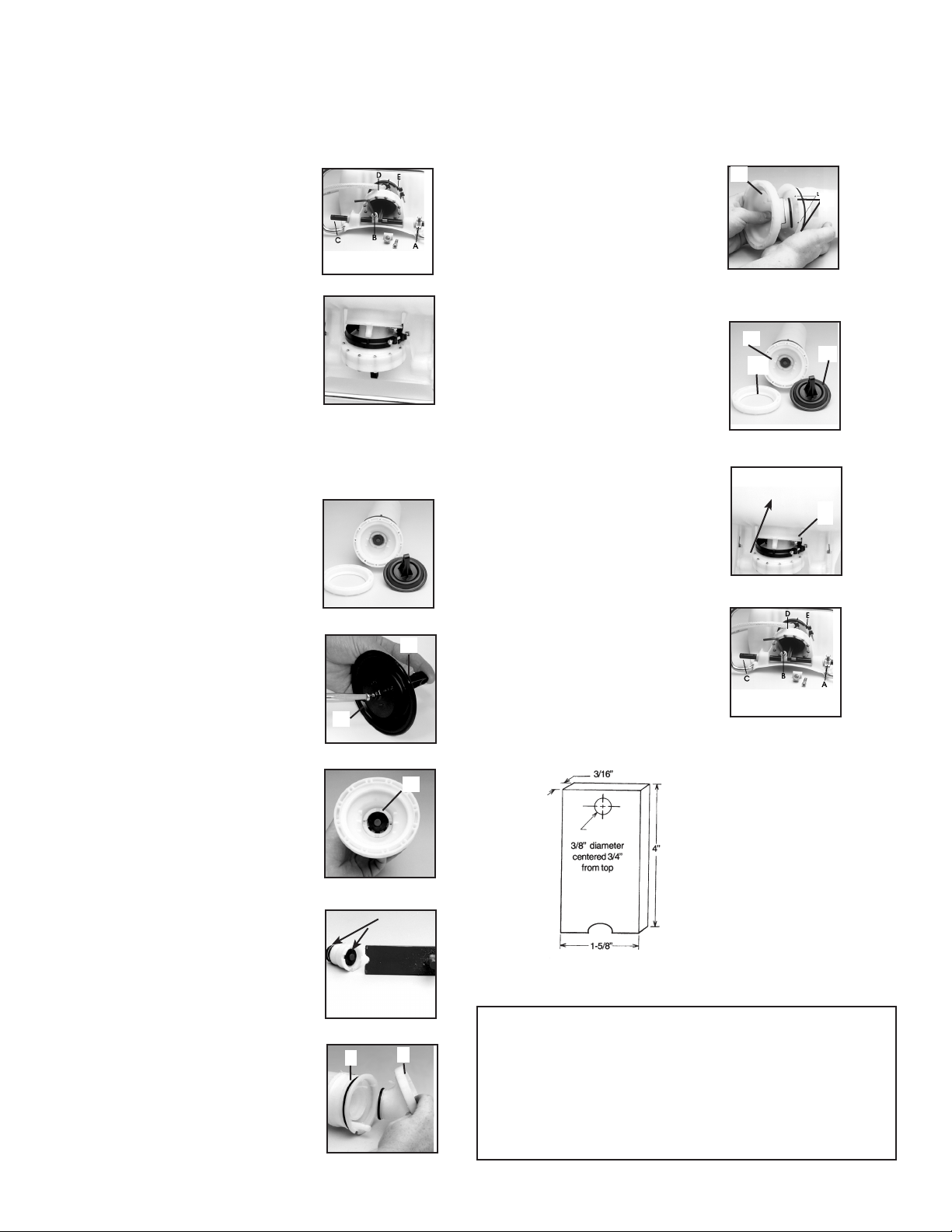

Diaphragm Pump Repair Kit ( # 0610406-K)

1. Using a 13mm socket wrench,

remove handle bolts and loosen the

stop plate (A) and remove the two

allen head screws (B) that hold the

connecting pieces to the pump rod.

Figure 1.

2. With unit laying on its back

with pump assembly facing you,

remove the pump rod (C). Loosen

hose clamp and remove pressure

hose (D). Caution: There may be

liquid inside the hose and pressure

cylinder even when the tank is

empty. Wear protective gloves.

Next, loosen the clamp at the base

of the sprayer (E). Figure 2.

3. Push the pressure cylinder

approximately 1/2" out of the

bottom of the tank. Then turn the

pump assy. 180 degrees. Note:

Wooden block may be used to

tap the pump assembly through

bottom of tank. Remove pressure

regulating valve, if equipped before

removal of cylinder.

4. Next remove the 12 torx screws

that hold the flange in place. The

flange and diaphragm can then

be removed. Figure 3. Note: For

clarity the pressure cylinder is

shown removed from the tank.

5. To replace the diaphragm,

remove the connecting rod retaining

screw (G) from the plunger and

lever (F). Replace the diaphragm

and reassemble. See Figure 4.

6. The valve assy. (H) is removed

using a locally made tool. Remove

red valve plate retaining pin using

needle nose pliers, then insert tool

into slots. See Figure 5. Use a

screwdriver to rotate tool counter

clockwise.

7. The valve plates and O-rings

can now be replaced. The bottom

valve plate is secured into place

with the red retaining pin. Push pin

into place using needle nose pliers.

Figure 6.

8. The pump housing (I) is separa-

ted from the pressure cylinder (J)

by pulling it off. Figure 7. The O-

ring can then be replaced.

Figure 6.

Figure 7.

Figure 5.

Figure 4.

Figure 3.

Figure 1.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 2.

L

M

N

P

O

K

G

F

H

I

J

9. When reassembling the pump

housing to the pressure cylinder, be

sure the square tab on the pump

housing (K) is aligned in the notch.

See arrows (L) on the pressure

cylinder in Figure 8. Be careful not to

pinch or nick the O-ring.

Note: Grease O-rings for re-assembly.

Screw the valve assembly into the

cylinder.

10. Place diaphragm assembly (O)

onto the pump housing (M). Place

the flange (N) over the diaphragm.

Reinstall the 12 torx screws around

the outside diameter of the flange.

Figure 9.

11. Lubricate the large O-ring and

then push the pressure cylinder into

the tank being careful not to pinch

the large O-ring (P).

Note: Wooden block may also be

used for installation of the pressure

cylinder.

12. Tighten pump clamp securely

(E). Install pump rod (C). Reinstall

the connecting pieces and allen head

screws (B). Reinstall the stop plate

(A) making sure that the bolt goes

through the rear hole. Reinstall the

hose and hose clamp making sure it

is firmly secured (D).

INSTALLATION INSTRUCTIONS

9

Note: Always wear rubber gloves, safety goggles and

appropriate protective clothing when repairing a sprayer. Work

in a well ventilated area. Prior to repair, flush unit with water by

filling, then spraying the water into an appropriate container or

area. Ensure that all pressure is released by locking the shut-off

valve in the open position. Once a repair is completed, fill the

unit with clean water, pressurize, and check for leaks. If the

sprayer leaks, DO NOT USE. Repair leaks and recheck.

Tools needed for kit installation: 6mm Allen Head Wrench, Flat Screwdriver, 11mm Wrench or Cresent Wrench, Long Nose Pli-

ers, Hammer, 13mm Socket or Wrench, T-25 Torx Screwdriver, Grease or Petroleum Jelly, 2X4 Piece of wood 18” long

Loading ...

Loading ...

Loading ...