Loading ...

Loading ...

Loading ...

14

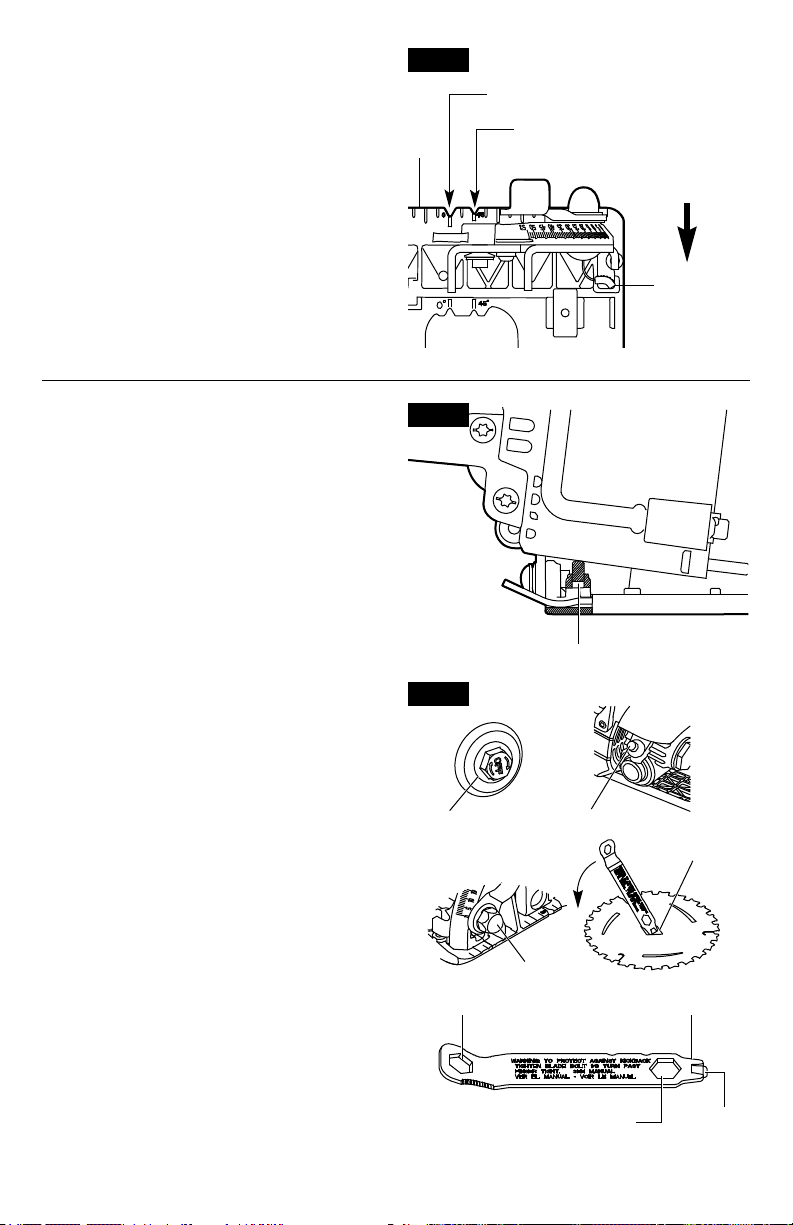

Fig. 6

45° Bevel

Cuts

45° Stop

Spring

Push the 45°

Stop Spring

In Direction

Of Arrow

For Bevel

Adjustments

Above 45°

Foot

0° Cuts

LINE GUIDE (FIG. 6)

For a 0° cut, use the large notch in the foot

for guidance . For 45° bevel cuts, use the

small notch (Fig. 6). The cutting guide notch

will indicate an approximate line of cut. Make

sample cuts in scrap lumber to verify the

actual line of cut. This will be helpful because

of the number of different blade types and

thicknesses available. To ensure minimum

splintering on the good side of the material to

be cut, face the good side down.

MAXIMUM DEPTH OF CUT STABILITY

ADJUSTMENT

Note: Feature is set during assembly.

Adjustment may be required due to wear and

tear on the tool.

Remove the battery pack from the circular saw

and set the saw to zero bevel. Place the foot plate

on a level surface with rear of foot over hanging

work the bench by about 2 inches. Loosen the

depth-adjustment lever. Set the saw to maximum

depth of cut. If the adjustment set screw is in

contact with the motor housing prior to achieving

maximum depth of cut, lower set screw using a

1/18” Allen wrench until the maximum depth of

cut is reached. If the set screw is not in contact

with the motor housing when the maximum depth

of cut is reached, raise the set screw until it just

engages the motor housing (Fig. 7a).

WRENCH USAGE (FIG. 7B FIG. 8)

The wrench provided has several functions in

addition to loosening/tightening the blade bolt

(Fig. 7b):

1. Loosening/tightening the blade bolt (1/2”

wrench).

2. Loosening/tightening the combo oil plug/

lock-button assembly (1/2” wrench).

3. Loosening/tightening bevel/depth levers

when levers are over tightened or additional

tightening is needed (9/16” wrench).

4. Blade diamond arbor knock out (wedge

feature).

Storage is provided on the tool (Fig. 1a). The

wrench is fully seated when the second lock

detent is engaged.

Fig. 7b

1 2

4

3

1/2" Wrench Wedge Feature

Slotted

Driver

9/16" Wrench

Fig. 7a

Set Screw

Loading ...

Loading ...

Loading ...