Loading ...

Loading ...

Loading ...

POSUTION WELDING

WELD

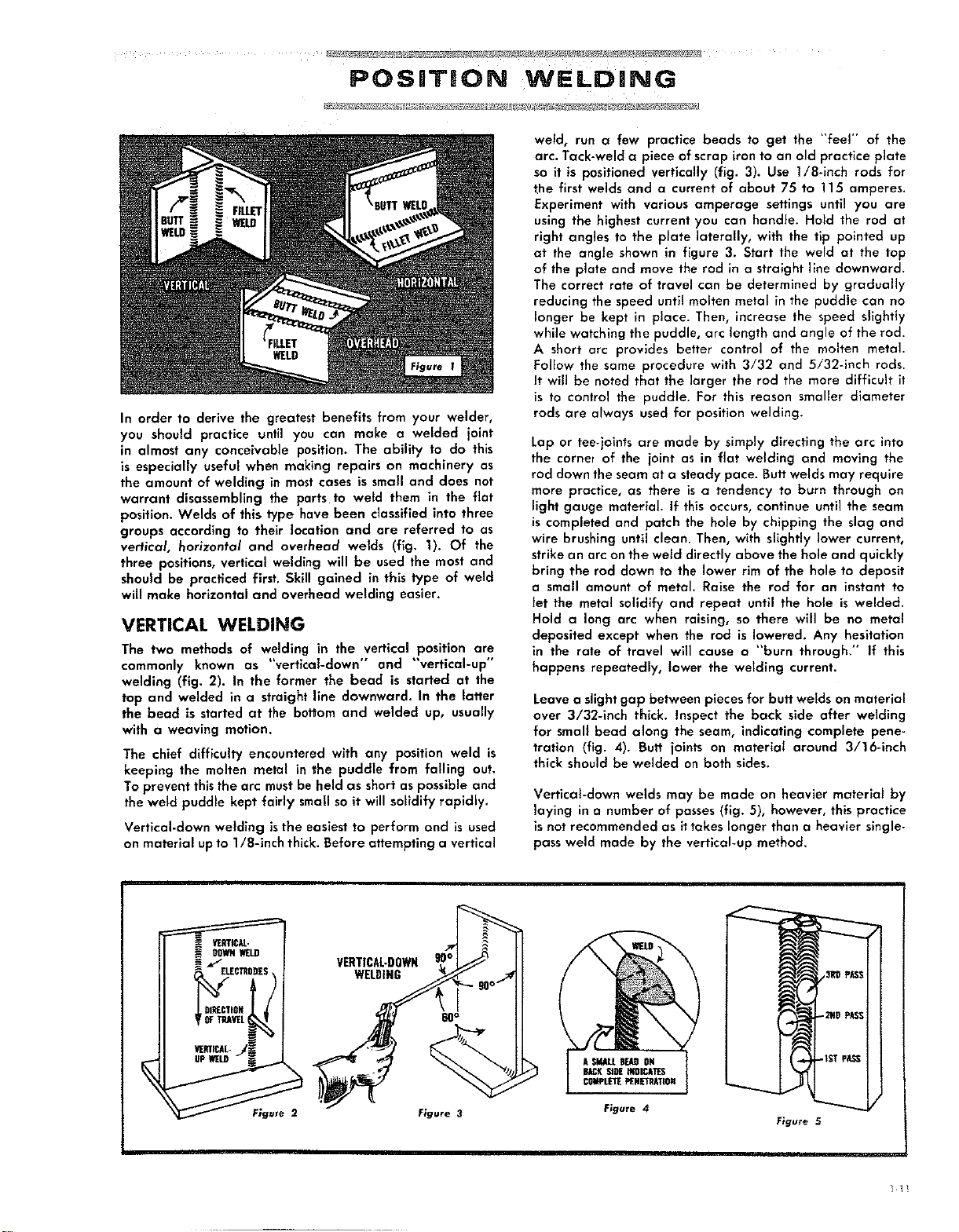

In order to derive the greatest benefits from your welder,

you should practice until you can make a welded joint

in almost any conceivable position. The ability to do this

is especially useful when making repairs on machinery as

the amount of welding in most cases is small and does not

warrant disassembling the parts to weld them in the flat

position. Welds of this type have been classified into three

groups according to their location and are referred to as

vertical, horizontal and overhead welds (fig. 1). Of the

three positions,vertical welding will be used the most and

should be practiced first. Skill gained in this type of weld

will make horizontal and overhead welding easier.

VERTICAL WELDING

The two methods of welding in the vertical position are

commonly known as "vertlcal-down" and "'vertical-up"

welding (fig. 2). In the former the bead is started at the

top and welded in a straight line downward. In the latter

the bead is started at the bottom and welded up, usually

with a weaving motion.

The chief difficulty encountered with any position weld is

keeping the molten metal in the puddle from falling out,

To prevent this the arc mustbe held as short as possible and

the weld puddle kept fairly small so it will solidify rapidly.

Vertical-down welding isthe easiest to perform and is used

on material upto l/B-inch thick. Before attempting a vertical

weld, run a few practice beads to get the "feel" of the

arc. Tack-weld a piece of scrap iron to an old practice plate

so it is positioned vertically (fig. 3). Use 1/8-inch rods for

the first welds and a current of about 75 to 115 amperes.

Experiment with various amperage settings until you are

using the highest current you can handle. Hold the rod at

right angles to the plate laterally, with the tip pointed up

at the angle shown in figure 3. Start the weld at the top

of the plate and move the rod in a straight line downward.

The correct rate of travel can be determined by gradually

reducing the speed until molten metal in the puddle can no

longer be kept in place. Then, increase the speed slightly

while watching the puddle, arc length and angle of the rod.

A short arc provides better control of the molten metal.

Follow the same procedure with 3/32 and 5/32-inch rods.

It will be noted that the larger the rod the more difficult it

is to control the puddle. For this reason smaller diameter

rods are always used for position welding.

Lap or tee-joints are made by simply directing the arc into

the corner of the joint as in flat welding and moving the

rod down the seam at a steady pace. Butt welds may require

more practice, as there is a tendency to burn through on

light gauge material. If this occurs, continue until the seam

is completed and patch the hole by chipping the slag and

wire brushing until clean. Then, with slightly lower current,

strike an arc on the weld directly above the hole and quickly

bring the rod down to the lower rim of the hole to deposit

a small amount of metal. Raise the rod for an instant to

let the metal solidify and repeat until the hole is welded.

Hold a long arc when raising, so there will be no metal

deposited except when the rod is lowered. Any hesitation

in the rate of travel will cause a "burn through." If this

happens repeatedly, lower the welding current.

Leave a slight gap between pieces for butt welds on material

over 3/32-inch thick. Inspect the back side after welding

for small bead along the seam, indicating complete pene-

tration (fig. 4). Butt joints on material around 3/16-inch

thick should be welded on both sides.

Vertical-down welds may be made on heavier material by

laying in a number of passes (fig. 5), however, this practice

isnot recommended as ittakes longer than a heavier single-

pass weld made by the vertical-up method.

DOWNWELD

IRSD£_

VERTICAL-DOWN9_

_ure 3

/3RO PASS

-2gB PSi;

ASM,ALLS_ OP4

g_K SiDE|IIOBAWN

COIIPLET_P£WET_Tt0g

Figure 4

Figure 5

iii

Loading ...

Loading ...

Loading ...