Loading ...

Loading ...

Loading ...

pipe connections points DO NOT leak, replace

the valve cover on the outside unit and wrap

and insulate the piping connections of the

indoor unit.

BEFORE TEST RUN

Using a soft brush or spray bottle, apply a soapy

water solution to all of the pipe connection points of

the indoor and outdoor units, watching to see if any

bubbles form. The presence of bubbles indicates

there is a leak.

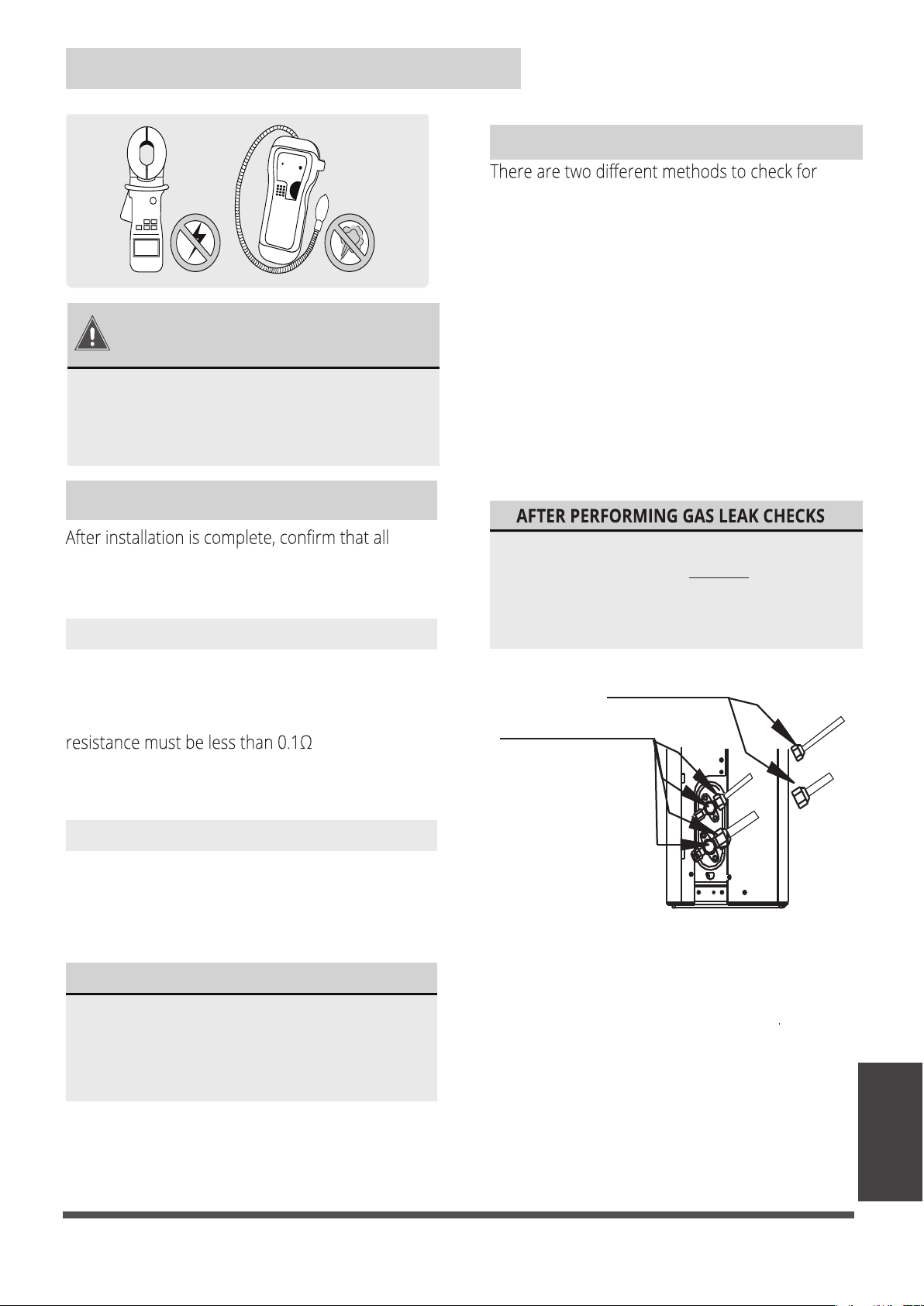

gaseous leaks. Use Fig. 8.1 below as a guide for

the critical points to check for leaks.

Soap and Water Method

Leak Detector Method

If using a leak detector, refer to the device’s

operation/instruction manual for proper usage

instructions.

Gas Leak Checks

IF ELECTRICAL LEAKAGE IS DETECTED

unit immediately and call a licensed

If electrical leakage is detected, turn o the

the leakage.

electrical wiring has been installed in accordance

with local and national regulations, and according

to the installation manual.

Check Grounding Work

Measure grounding resistance by visual detection

and with a grounding resistance tester. Grounding

.

NOTE: This may not be required for some

locations in North America.

Check for Electrical Leakage

During the Test Run, use an electroprobe and

multimeter to perform a comprehensive electrical

leakage test.

NOTE: This may not be required for some

locations in North America.

Electrical Safety Checks

DURING TEST RUN

WARNING – RISK OF

ELECTRICAL SHOCK

ALL WIRING MUST BE INSTALLED BY A

LOCAL, STATE, AND NATIONAL ELECTRICAL

CODES.

Check-point of indoor unit

Check-point of outdoor unit

A

B

C

D

Fig. 8.1

Electrical and

Gas Leak Checks

Electrical and Gas leak Checks

A: Low pressure stop valve

B: High pressure stop valve

C & D: Indoor unit are nuts

electrician to nd and resolve the cause of

LICENSED ELECTRICIAN AND COMPLY WITH

After confirming that all of the refrigerant

Page 42

Loading ...

Loading ...

Loading ...