Loading ...

Loading ...

Loading ...

Make sure engine stops; then restart

engine and continue.

• Fue_Tank - Do not use saw if fuet

tank shows signs of damage or

leaks.

• Oil Tank - Do not use saw if oil tank

shows signs of damage or leaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

Bar Clamp Nut

Chain

Muffler

Cylinder Shield

Air Filter

Clutch Drum/Sprocket

Handle Screws

Vibration Mounts

Starter Housing

Handguard

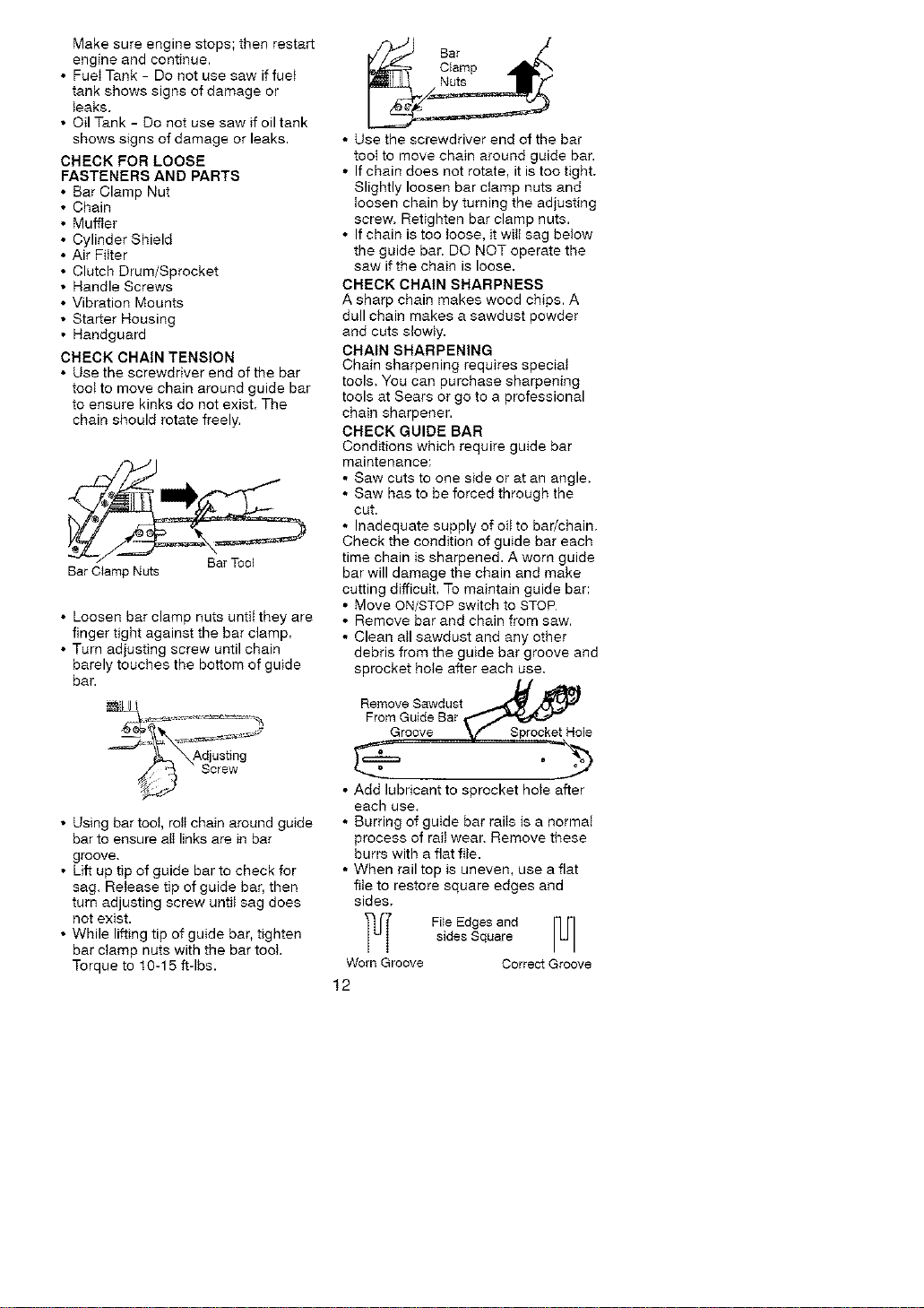

CHECK CHAIN TENSION

• Use the screwdriver end of the bar

toot to move chain around guide bar

to ensure kinks do not exist. The

chain should rotate freely.

Bar Ctamp Nuts

• Loosen bar clamp nuts untit they are

finger tight against the bar clamp.

• Turn adjusting screw until chain

barely touches the bottom of guide

bar.

• Using bar toot, roll chain around guide

bar to ensure all links are in bar

groove.

• Lift up tip of guide bar to check for

sag. Release tip of guide bar, then

turn adjusting screw until sag does

not exist.

• While lifting tip of guide bar, tighten

bar clamp nuts with the bar tool.

Torque to 10-15 ft-lbs.

• Use the screwdriver end of the bar

toot to move chain around guide bar.

• If chain does not rotate, it is too tight.

Slightly loosen bar clamp nuts and

loosen chain by turning the adjusting

screw. Retighten bar clamp nuts.

• If chain is too loose, it wilt sag below

the guide bar. DO NOT operate the

saw if the chain is loose.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly.

CHAIN SHARPENING

Chain sharpening requires speciat

tools. You can purchase sharpening

tools at Sears or go to a professional

chain sharpener.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the

cut.

• Inadequate supply of oil to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult, To maintain guide bar:

• Move ON/STOP switch to STOP

• Remove bar and chain from saw.

• Clean all sawdust and any other

debris from the guide bar groove and

sprocket hole after each use.

Remove Sawdust__ 0

From Guide Bar

Groove le

• Add lubricant to sprocket hole after

each use.

• Burring of guide bar rails is a normat

process of raii wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a flat

file to restore square edges and

sides.

]_r Fi_eEdges andsides Square [_]

Worn Groove Correct Groove

12

Loading ...

Loading ...

Loading ...