Loading ...

Loading ...

Loading ...

• Use the wire included inthe kit or a small paper clip

to free the foreign materials clogging or restricting the

nozzle.

Insertwire intothe nozzle orifice,andturn it

back and forth to clear anyobstruction.

Remove additional debris by back flushing water

supply through wand. Back flush between 30 to 60

seconds. Turn wand to stream spray and move

nozzle from low to high pressure while flushing.

* Reinstall orifice into nozzle. DO NOT overtighten.

o Reconnect nozzle to nozzle extension.

, Reconnect with the water supply, turn ON the water

and start the engine.

, Test the pressure washer by operating with nozzle in

the high and the low pressure positions.

O-RING MAaNTENANCE

Through the normal operation of your pressure washer,

O-Rings, which keep the connections of the hoses and

gun tight and leak-free may become worn or damaged.

Provided with your pressure washer is an O-Ring

Maintenance Kit which provides replacement O-Rings,

Rubber Washer and Quick Connect filter.

To remove a worn or damaged O-Ring:

= Use a small flathead screwdriver to get underneath

the O-Ring and pry it off.

Parts in the O-Ring Kit Include;

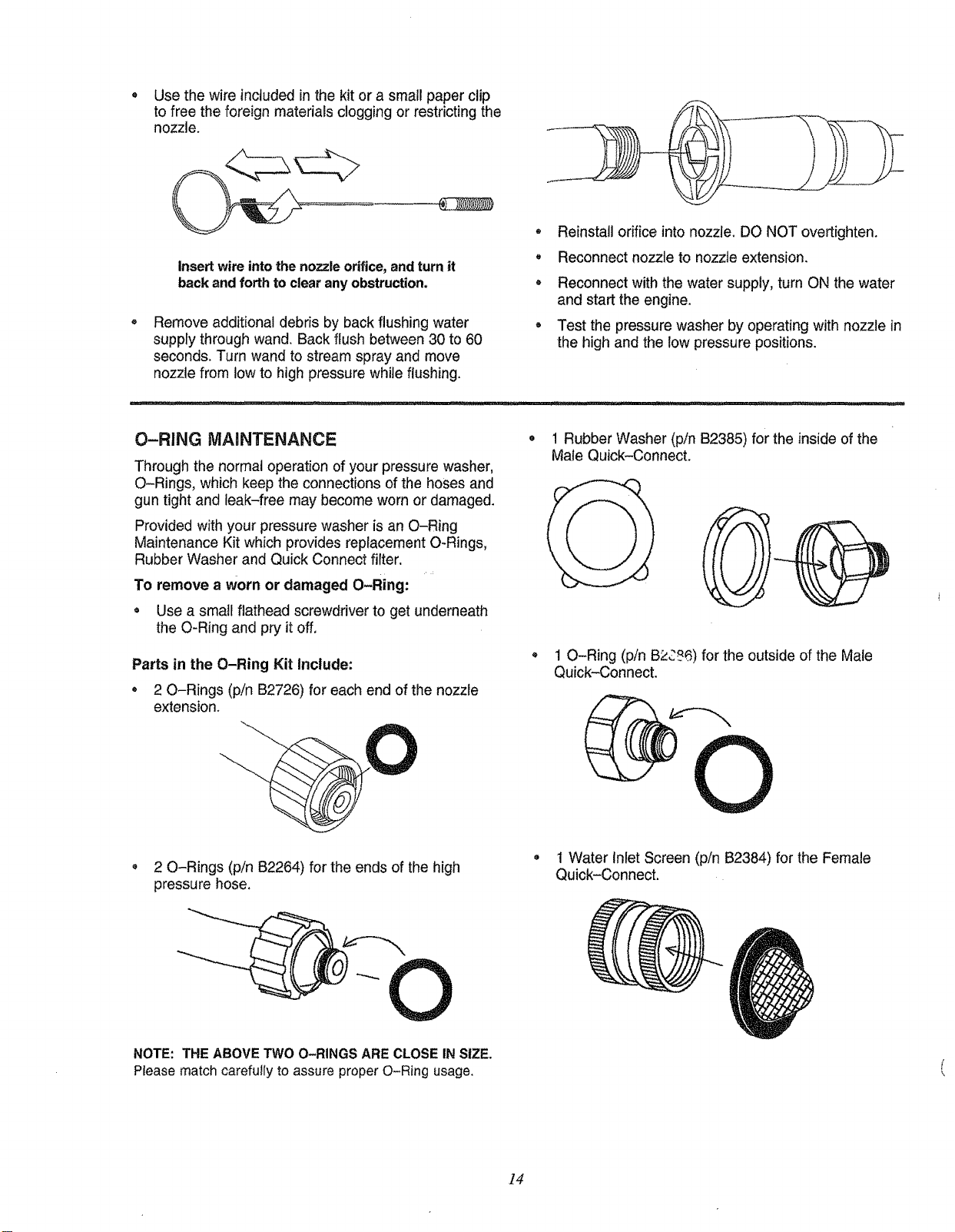

* 2 O-Rings (pin B2726) for each end of the nozzle

extension.

1 Rubber Washer (pin B2385) for the inside of the

Male Quick-Connect.

* 1 O-Ring (p/n B2C76) for the outside of the Male

Quick-Connect.

O

, 2 O-Rings (pin 82264) for the ends of the high

pressure hose.

• 1 Water Inlet Screen (p/n B2384) for the Female

Quick-Connect.

NOTE: THE ABOVE TWO O-RINGS ARE CLOSE IN SIZE.

Ptease match carefully to assure proper O-Ring usage,

]4

Loading ...

Loading ...

Loading ...