Loading ...

Loading ...

Loading ...

Oncemade,theseadjustmentsshouldremainaccurate.Takea littletimenowtofollow

thesedirectionscarefullytomaintaintheaccuracyofwhichyoursawiscapable.

RAILLOCKADJUSTMENT

(TighteningFenceClampingSystem) FIG.18

1.Locktheraillocklever(W).

2.Ontheundersideofthesaw,loosenthenut(LL)(Fig.18).

3.Tightenthehexrod(MM)untilthespringonthelockingsystem

iscompressedcreatingthedesiredtensionontheraillocklever. MM

Retightenthejamnutagainstthehexrod.

4.Flipthesawoverandcheckthatthefencedoesnotmovewhen LL

thelockleverisengaged.Ifthefenceisstillloose,tightenthe

springfurther.

RIPSCALEADJUSTMENT FIG,19

(CalibratingRipScale)

1.Unlocktheraillocklever(W).

2.Setthebladeat0° bevelandmovethe

fenceuntilitisflushwiththeblade.

3.Locktheraillocklever.

4.Loosenthescrews(NN,Fig.16)in

the rip scalepointerwitha Phillips

screwdriverandresettheredlineto0°

onthescale.

5.Tightenthescrewsbackintotherail. W

NOTE:Theripscaleonlyreadscorrectly

whenthefenceismountedontherightside

oftheblade.

BLADEALIGNMENTADJUSTMENT

(BladeParallelto MiterSlot)

AWARNING:Cut Hazard. Check the blade

at 0 ° and 45 ° to make sure blade does not

hit the throat plate, causing personal injury. FIG. 20

If the blade appears to be out of alignment

with the miter slot on the table top, it will

require calibration for alignment. To realign

the blade and miter slot, use the following

procedure:

1. Locate the black Allen Iocator screws

(OO) that hold up the trunnion to the

bottom of the table in the rear of the

saw.

2. Loosen both screws and align the blade

with the miter slot. Be sure to measure

between the miter slot and the back and

front of the blade to ensure parallelism.

3. Snugly tighten the screws to secure the

trunnion and blade assembly to the table CO

at the parallel position.

FENCE ALIGNMENT ADJUSTMENT (FIG. 4, 5) (Blade Parallel to Fence)

If you experience fence alignment problems and want to correct an out of parallel between

the fence and the blade, be sure to check the alignment of the blade to the miter slot first.

After confirming that those elements are aligned, proceed with alignment of the blade to the

fence using the following procedure:

1. Unlock the rail lock lever (W) and locate the two fence Iocator screws (AA) that support

the fence on the front and rear rails.

2. Loosen the rear Iocator screw and adjust the position of the fence in the groove on the

fence until it sets the fence face parallel to the blade. Make sure you measure from the

fence face to the front and back of the blade to ensure alignment.

3. Tighten the Iocator screw and repeat on the left side of the blade.

4. Check rip scale adjustment.

BEVEL STOP AND POINTER ADJUSTMENT

(Calibrating Bevel Scale)

Calibrating the bevel system on the saw may require two separate steps, one for the bevel

scale and another for the bevel pointer. The scale should always be checked first followed

by adjustments to the red pointer.

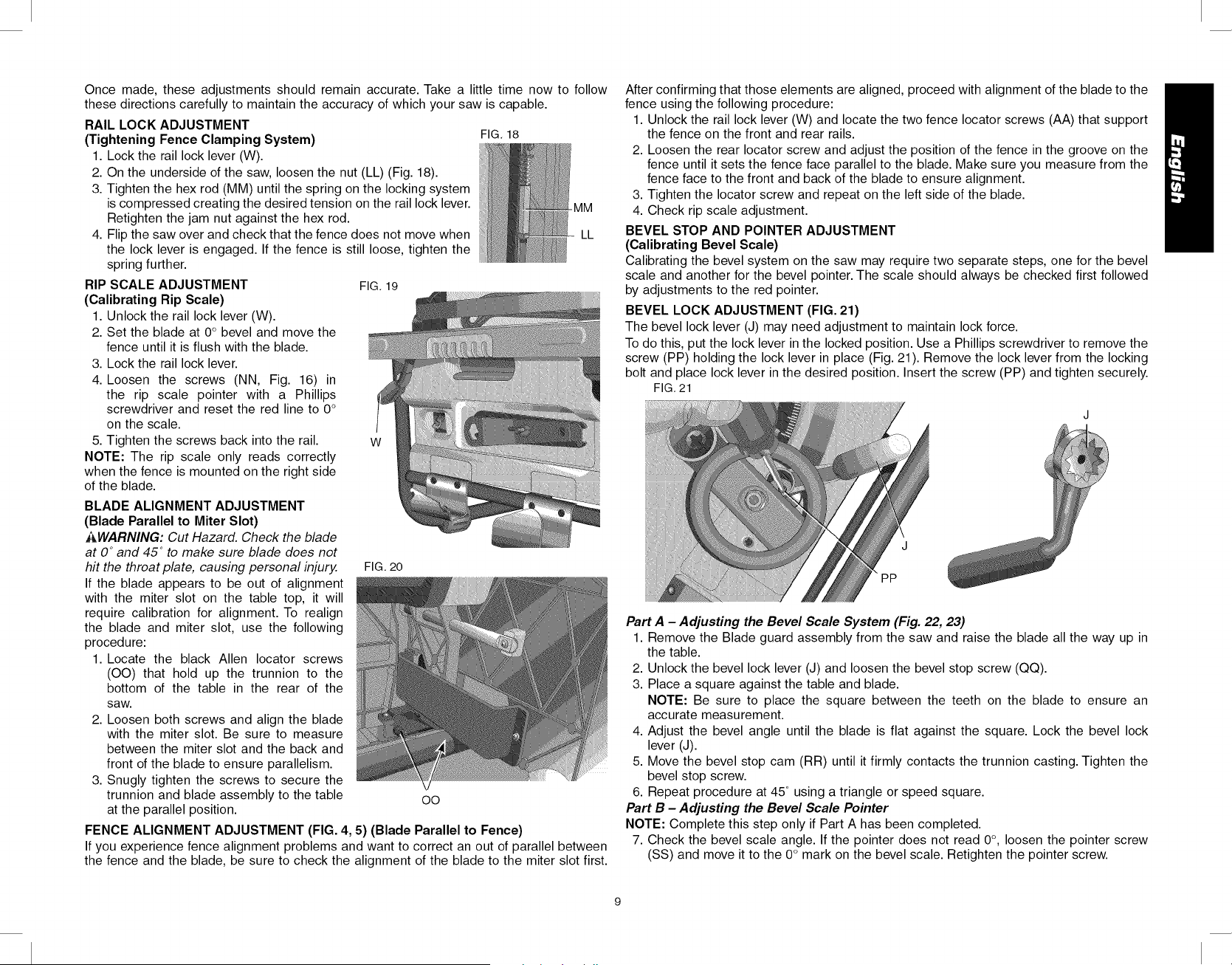

BEVEL LOCK ADJUSTMENT (FIG. 21)

The bevel lock lever (J) may need adjustment to maintain lock force.

To do this, put the lock lever in the locked position. Use a Phillips screwdriver to remove the

screw (PP) holding the lock lever in place (Fig. 21 ). Remove the lock lever from the locking

bolt and place lock lever in the desired position. Insert the screw (PP) and tighten securely.

FIG. 21

PP

Part A - Adjusting the Bevel Scale System (Fig. 22, 23)

1. Remove the Blade guard assembly from the saw and raise the blade all the way up in

the table.

2. Unlock the bevel lock lever (J) and loosen the bevel stop screw (QQ).

3. Place a square against the table and blade.

NOTE: Be sure to place the square between the teeth on the blade to ensure an

accurate measurement.

4. Adjust the bevel angle until the blade is flat against the square. Lock the bevel lock

lever (J).

5. Move the bevel stop cam (RR) until it firmly contacts the trunnion casting. Tighten the

bevel stop screw.

6. Repeat procedure at 45 ° using a triangle or speed square.

Part B - Adjusting the Bevel Scale Pointer

NOTE: Complete this step only if Part A has been completed.

7. Check the bevel scale angle. If the pointer does not read 0°, loosen the pointer screw

(SS) and move it to the 0° mark on the bevel scale. Retighten the pointer screw.

Loading ...

Loading ...

Loading ...