Loading ...

Loading ...

Loading ...

10 11

INSTALLATION INSTALLATION

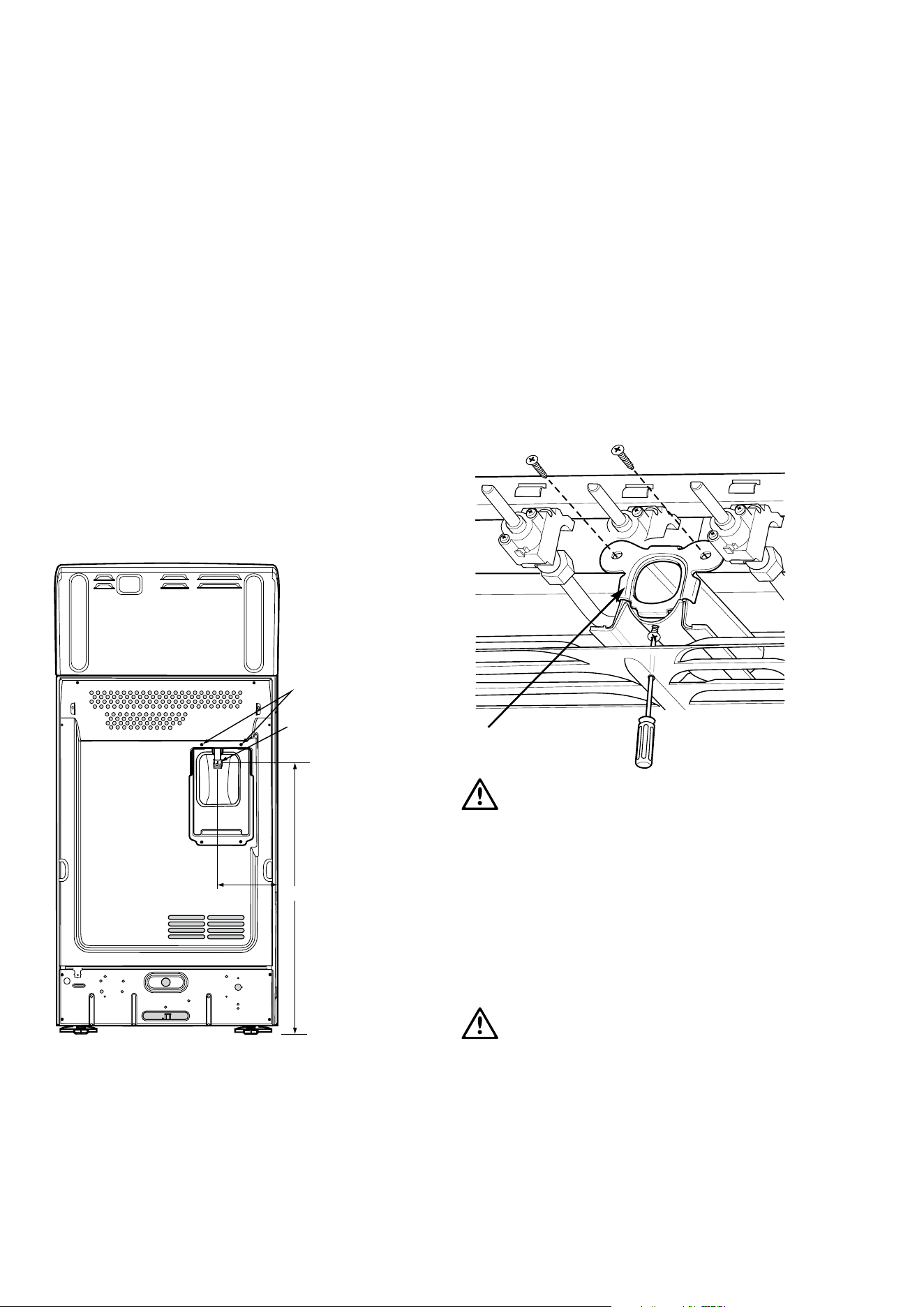

Wiring connection for gas cooker

To allow for disconnection of the appliance after installation,

the plug must be accessible after installation�

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard�

Gas connection

Read these points before connecting to the gas supply:

• The cooker inlet connection point has a ½" BSP external

thread� See diagram below�

• An NG regulator or a LPG test point fitting is supplied�

• It is recommended to fit the regulator or test point fitting

to the appliance connection point, then fit either hard

piping or a high level flexible connection (AS/NZS 5601�1

clauses 5�9 and 6�10�1�9) which is then attached to the

consumer hard piping�

• Ensure installation allows withdrawal of appliance�

Restraining device

anchor points

Gas connection

point

650mm

150mm

Operation on universal LPG/propane

1� The appliance inlet fitting provided MUST be orientated

so that the pressure nipple is accessible�

2� The inlet fitting has ½" BSP internal thread at the inlet

and outlet�

Operation on SNG

• If the cooker is to be used with SNG, then the grill burner

MUST be modified by the replacement of the shutter,

which fits into the throat of the grill burner�

• A conversion kit can be obtained by contacting the

Customer Care Centre�

Restraining Device

Anchor Points

Connection

Gas

Point

150mm

650mm

Grill shutter

WARNING

WARNING

Disconnect electric power before removing control panel�

1� Remove the control panel�

2� Remove the existing NG shutter securing screw (refer to

diagram above) and slide upwards to disengage from

grill burner�

3� Slide the SNG shutter into position and secure with

screws�

Testing the gas cooker

WARNING

WARNING

You MUST test the cooker after installation, before you hand

it over to the customer.

You MUST have a manometer and a connecting tube.

GAS TYPE NATURAL GAS UNIVERSAL LPG PROPANE

Supply pressure at inlet to appliance

regulator (if fitted)

1�13 (kPa)

Minimum

2�75* (kPa) 2�75* (kPa)

Operating pressure at

appliance test point

1�00 (kPa) 2�75 (kPa) 2�75 (kPa)

* If the regulator is placed upstream of the cooker inlet, as is normal for cookers operating on LPG, then the supply pressure and

operating pressure are the same�

The following table shows the injector sizes for each burner�

INJECTOR NATURAL GAS UNIVERSAL LPG PROPANE

Low heat burner 1�00 mm 0�55 mm 0�62 mm

Medium heat burner 1�35 mm 0�70 mm 0�82 mm

High heat burner 1�60 mm 0�90 mm 0�95 mm

Intense heat wok burner 1�75 mm 1�00 mm 1�00 mm

Grill – main injector 1�50 mm 0�82 mm 0�82 mm

Oven – main injector 1�60 mm 0�82 mm 0�95 mm

Oven – bypass screw 0�73 mm 0�45 mm 0�45 mm

Checking pipe size

To work out a suitable pipe size for connection use the information in this table�

NATURAL GAS UNIVERSAL LPG PROPANE

Configuration

STD

Hob

WOK Hob

STD

Hob

WOK

Hob

STD

Hob

WOK

Hob

Hourly gas consumption for

cooker

58�1MJ 60�2MJ 45�7MJ 48�2MJ 56�5MJ 58�3MJ

Also use information about the length of the run, number of

elbows, tees and bends, the available service pressure and

the supply requirements� AS/NZS 5601�1 will help you with this

matter�

Operation ON NG

• The appliance regulator MUST be orientated so that the

pressure nipple is accessible�

• The arrow showing the direction of flow MUST be

pointed correctly�

• The regulator has a ½” BSP internal thread at the inlet

and outlet�

Gas requirements

This appliance must be installed by an authorised person,

according to all codes and regulations of:

• AS/NZS 5601�1 (particular attention to clause 6�10�1

and figure 6�3 on page 97, and clause 6�10�1�11)

• Local gas fitting regulations, municipal building codes

and other statutory regulations�

Unpacking

When packaging is removed from product you will notice

there are several items nested in the packaging base�

The burner crowns, burner caps and trivets can be fitted to

the hob�

The regulator or test point fitting installation is described in the

front of the manual with UNPACKING�

The cookers come in three gas types:

Natural gas, Propane and Universal LPG� If the cooker is

required to use ULPG, a conversion kit can be obtained by

contacting the Customer Care Centre for details� Before

installation, check that the cooker is suitable for the gas supply

by looking at the data plate behind the bottom of the oven

door�

The following table shows the supply and operating pressures

for various supplies�

Restraining Device

Anchor Points

Connection

Gas

Point

150mm

650mm

NG Regulator

Gas flow

Pressure test

point

1/2" BSP

Internal thread

INSTALLATION

Loading ...

Loading ...

Loading ...