Loading ...

Loading ...

Loading ...

_HI:._]m::l'_o41JW|l_[_[eLWlle]

CIRCLE CUTTING GUIDE OPERATFON

),A WARNING I

Unplug the tool from tt3epower source before

changing accessories, changing bits and making

adjustments.

Before turning the tool ON, check to make sure bit

and all accessory fasteners are securely tightened.

1. Mark the centre of the circle you wish to cut on the

workpiece and drill a 6 mm or 151_"pilot hole.

2. Adjust Guttingbit depth to 118"longer than the

thickness of the material being cut (see Fig. 5).

3. Adjust the circle cutting guide radios by loosening

pivot point knob, sliding it to the correct circle radius

and re-tightening in the desired location.

NOTE: Check circre cutting guide radius setting by

measuring from the pivot point to the outside of the

spiral bit.

4. Rest the edge of the freehand cuffing guide on the

workp=ece wuththe b t at an angle of about 45 (see

Fig, 13)• Insert the circle cutting guide pivot point into

the pilot hole drilled at the centre of the circle.

NOTE: DO NOT let the bit contact the workpiece

before switch is turned ON and the tool isup to furl

speed.

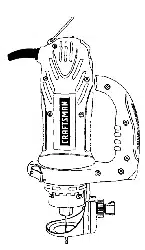

Fig. 13

CIRCLE CUTTING GUIDE OPERATION - cont'd

5. Turn the switch ON.

6.

7.

When the motor is up to fullspeed, slowly tip the tool

and circle cutting guide assembly to an Upright

position, letting the bit cut nte the workpiece (see Fig

f4J. Be careful to keep the p vo point ocated at the

centre of the circle to be cut. Once the tool has

reached the upright position and the bit has cut

through the workpiece, slowly move the tool in a

clockwise direction using slow steady pressure to

make the cut. Continue tocut the circle, keeping the

tool upright and rotating around the circle cutting

guide pivot point.

When cut is complete, turnthe tool OFF, wait until it

comes to a complete stop and remove it from the

workpiece.

Fig. 14

16

Loading ...

Loading ...

Loading ...