Loading ...

Loading ...

Loading ...

6. Liftuptopofguidebartocheckfor

sag.Releasetipofguidebar,then

turnadustingscrewclockwiseuntil

sagdoesnotexst.

7. Whileliftingtipofguidebar,tighten

barclampnutswithawrench.

8. Usescrewdrivertomovechain

aroundguidebar.

9. Ifchaindoesnotrotate,itistoo

tight.Slightlyloosenbarclamp

nutsandloosenchainbyturning

theadjustingscrewcounterclock-

wise.Retightenbarclampnuts.

10.Ifchainistooloose,itwillsagbe-

lowtheguidebar.DONOToperate

thesawifthechainisloose.

•_I_WARNING:Ifthesawisoperated

withaloosechain,thechaincould

jumpofftheguidebarandresultinse-

riousinjury.

CHECKCHAINSHARPNESS

A sharp chain makes wood chips. A dull

chain makes a sawdust powder and

cuts slowly. See CHAIN SHARPENINGin

the SERVICEAND ADJUSTMENTSsec-

tion.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the

cut.

• Inadequate supply of oil to the bar

and chain.

Check the condition of the guide bar be-

fore each use and each time the chain

is sharpened. A worn guide bar will

damage the chain and make cutting diffi-

cult.

After each use, with unit disconnected

from power source, clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

• Disconnect the chain saw from the

power source.

• Loosen and remove bar clamp nuts

and bar clamp. Remove bar and

chain from saw.

• Clean the oil holes and bar groove

after each 5 hours of operation.

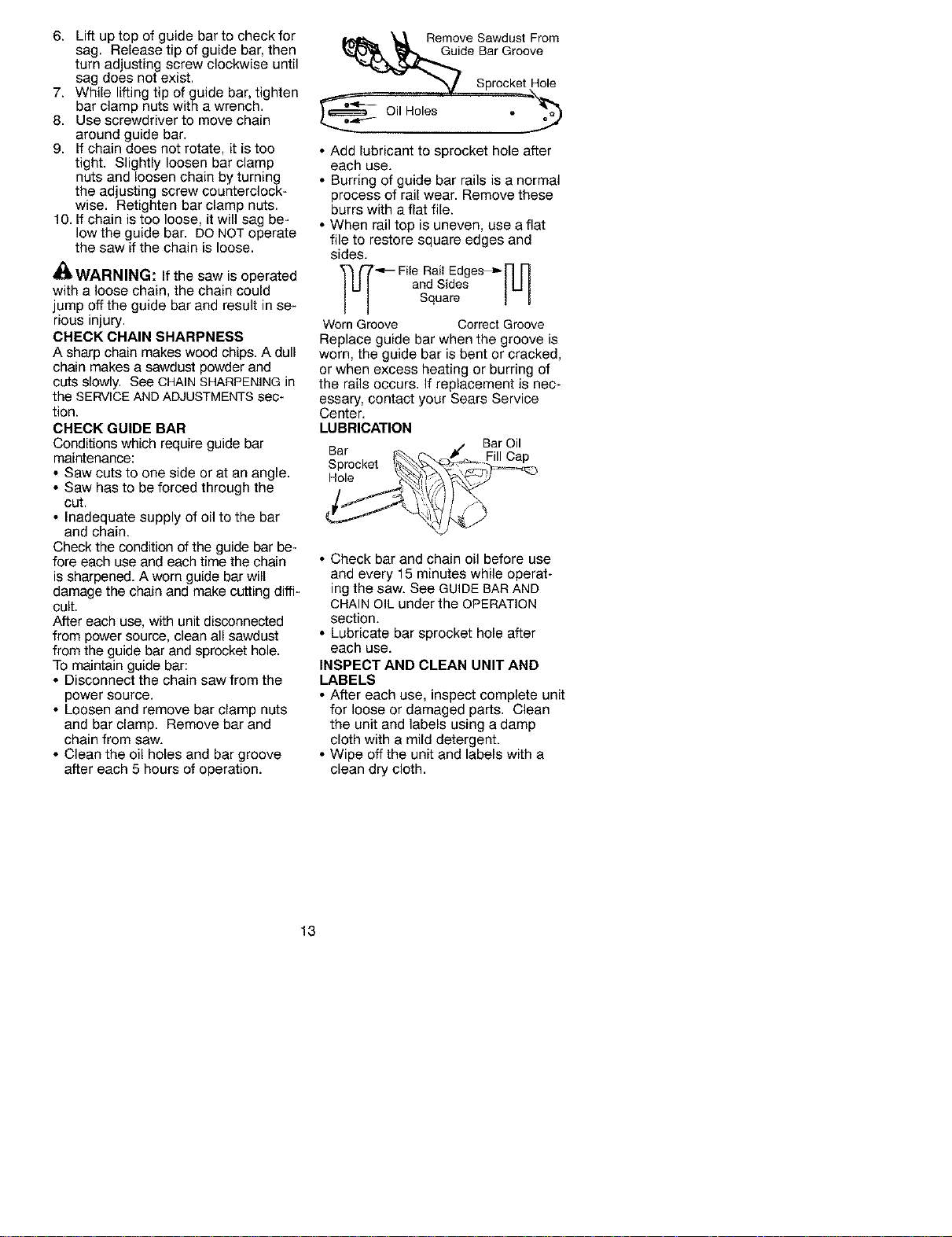

Remove Sawdust From

Guide Bar Groove

_ Sprocket Hole

a-_'--- Oil Holes o

• Add lubricant to sprocket hole after

each use.

• Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a flat

file to restore square edges and

sides.

'_-- File Rail Edge_r] N

andSides I U

Square I I

Worn Groove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of

the rails occurs. If replacement is nec-

essary, contact your Sears Service

Center.

LUBRICATION

BarOil

Bar --illCap

Sprocket

Hole

• Check bar and chain oil before use

and every 15 minutes while operat-

ing the saw. See GUIDE BAR AND

CHAIN OIL under the OPERATION

section.

• Lubricate bar sprocket hole after

each use.

INSPECT AND CLEAN UNIT AND

LABELS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit and labels using a damp

cloth with a mild detergent.

• Wipe off the unit and labels with a

clean dry cloth.

13

Loading ...

Loading ...

Loading ...