Loading ...

Loading ...

Loading ...

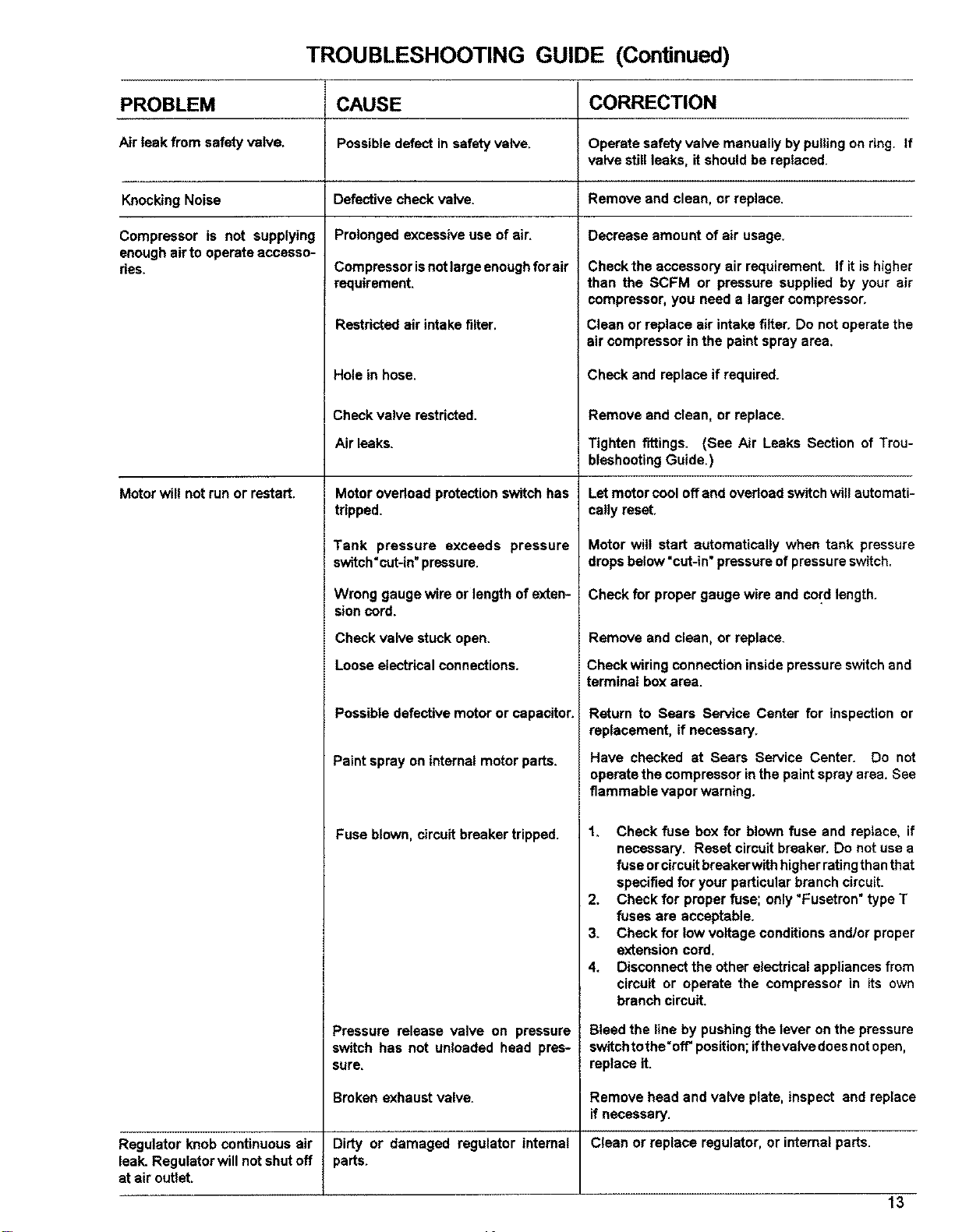

TROUBLESHOOTING GUIDE (Continued)

PROBLEM CAUSE CORRECTION

Air leak from safety valve. Possible defect in safety valve. Operate safety valve manually by puningon ring. tf

valve still leaks, it should be replaced.

Knocking Noise Remove and clean, or replace,

Decrease amount of air usage,Compressor is not supplying

enough air to operate accesso-

ries.

Motorwillnotrunor restart.

Regulator knob continuous air

leak, Regulator will not shut off

at air outlet.

Defective check valve.

Prolonged excessive use of air.

Compressor isnot large enough forair

requirement.

Restricted air intake filter,

Hole in hose,

Check valve restricted.

Airleaks.

Motor overload protection switch has

tripped.

Tank pressure exceeds pressure

switch"cut-in" pressure.

Wrong gauge wire or length of exten-

sion cord.

Check valve stuck open.

Loose electrical connections.

Possible defective motor or capacitor.

Paint spray on internal motor parts.

Fuse blown, circuit breaker tripped.

Pressure release valve on pressure

switch has not unloaded head pres-

sure.

Broken exhaust valve.

Dirty or damaged regulator internal

)arts.

Check the accessory air requirement. If it is higher

than the SCFM or pressure supplied by your air

compressor, you need a larger compressor.

Clean or replace air intake filter. Do not operate the

air compressor in the paint spray area.

Check and replace if required.

Remove and clean, or replace.

Tighten f_ings. (See Air Leaks Section of Trou-

bleshooting Guide,)

Let motor cool off and overload switch will automati-

cally reset.

Motor will start automaticatly when tank pressure

drops below "cut-in" pressure of pressure switch.

Check for proper gauge wire and cord length.

Remove and clean, or replace.

Check wiring connection inside pressure switch and

terminal box area.

Return to Sears Service Center for inspection or

replacement, if necessary.

Have checked at Sears Service Center. Do not

operatethe compressorinthepaintsprayarea.See

flammablevaporwarning,

1_ Check fuse box for blown fuse and replace, if

necessary. Reset circuitbreaker,Do not usea

fuse orcircuitbreakerwithhigherratingthanthat

specifiedfor yourparticularbranchcircuit.

2. Checkfor properfuse; only"Fusetron"type T

fuses are acceptable.

3. Checkfor lowvoltageconditionsand/orproper

extensioncord,

4, Disconnecttheotherelectricalappliancesfrom

circuit or operate the compressorin its own

branchcircuit,

Bleed the line by pushing the lever on the pressure

switch tothe=ofr' position;ifthevalve doesnot open,

replace it.

Remove head and valve plate, inspect and replace

if necessary,

Clean or replace regulator, or internal parts.

13

Loading ...

Loading ...

Loading ...