Loading ...

Loading ...

Loading ...

507295-02C Page 7 of 13mrcool.com

When converting a low NOx unit (designated by an L in

some model numbers) to propane, the NOx inserts must

be removed.

All LPG/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

For satisfactory operation, LPG/propane gas pressure

must be a minimum of 11” w.c. at the unit under full load.

Complete information regarding tank sizing for

vaporization, recommended regulator settings, and pipe

sizing is available from most regulator manufacturers and

LPG/propane gas suppliers.

Check all connections for leaks when piping is completed,

using a soapy, non-chlorine based solution. Some soaps

used for leak detection are corrosive to certain metals.

Carefully rinse piping thoroughly after completing

leak detection.

Danger of explosion. Can cause injury or product or

or other sources of ignition to check for leaks.

WARNING

the authority that has jurisdiction, black iron pipe shall

be installed at the gas valve and must extend outside

between the black iron pipe and the gas supply line.

CAUTION

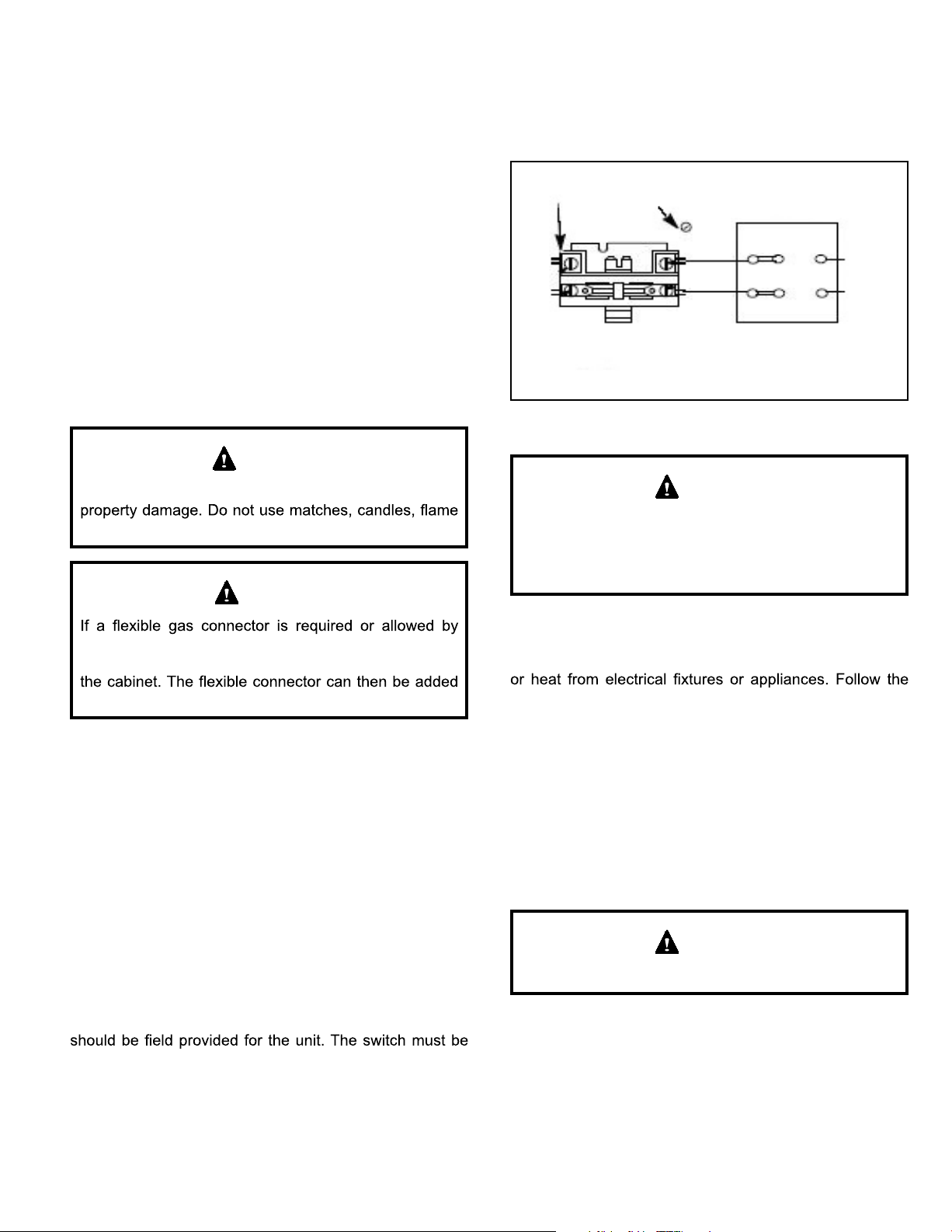

Electrical Wiring

See Figure 4 and Figure 5

All wiring should be done in accordance with the National

Electrical Code, ANSI/NFPA No. 70 (latest edition);

Canadian Electrical Code Part 1, CSA C22.1 (latest

edition); or local codes where they prevail. Use wiring with

a temperature limitation of 75°C minimum. Run the 208 or

230 volt, 60 hertz electric power supply through a fused

disconnect switch to the control box of the unit and connect

as shown in the wiring diagram located on the inside of the

control access panel.

Power supply to the unit must be N.E.C. Class 1, and must

comply with all applicable codes. A fused disconnect switch

separate from all other circuits. If any of the wire supplied

with the unit must be replaced, replacement wire must be

of the type shown on the wiring diagram. Electrical wiring

must be sized to carry minimum circuit ampacity marked

on the unit. Use copper conductors only. Each unit must

be wired with a separate branch circuit and be properly

fused.

Figure 5. 208/230 Line Voltage Wiring

SINGLE PHASE

POWER SUPPLY

GROUND

LUG

CONTACTOR

FIELD-SUPPLIED FUSED

OR CIRCUIT BREAKER

DISCONNECT

If 208 Volt is supplied, transformer connection must be

changed

When connecting electrical power and control wiring

to the unit, waterproof type connectors must be used

so that water or moisture cannot be drawn into the unit

during normal operation.

CAUTION

Thermostat

The room thermostat should be located on an inside

wall where it will not be subject to drafts, sun exposure,

manufacturer’s instructions enclosed with thermostat for

general installation procedure. Color-coded insulated wires

(#18 AWG) should be used to connect the thermostat to

the unit.

Four wires are required for cooling. The heat anticipator

setting is 0.75 amp.

Compressor

Units are shipped with compressor mountings factory-

adjusted and ready for operation.

Do not loosen compressor mounting bolts.

CAUTION

Loading ...

Loading ...

Loading ...