Loading ...

Loading ...

Loading ...

3DUW1XPEHU

23

For your safety, turn off electrical power supply at ser-

vice entrance panel before making any electrical con-

nections to avoid possible electric shock hazard. Fail-

ure to do so can cause severe personal injury or death.

Refer to the Control Supplement for additional

information, operating instructions and control

wiring diagram.

Wiring must be N.E.C. Class 1.

If rollout thermal fuse element wire supplied with

boiler must be replaced, type 200 °C wire or equiva-

lent must be used. If other original wiring supplied

with boiler must be replaced, use only type 105 °C

wire or equivalent.

Boiler must be electrically grounded as required

by National Electrical Code ANSI/NFPA 70–latest

edition.

Electrical installation must comply with:

1. National Electrical Code ANSI/NFPA 70–latest edition and any

other national, state, provincial or local codes or regulations.

2. In Canada, CSA C22.1 Canadian Electrical Code Part 1, and

any local codes

Wiring connections

1. Boiler is shipped with controls completely wired, except

spill switch and vent damper. See wiring diagram in Control

Supplement for details.

2. Installer must attach wiring diagram inside jacket door.

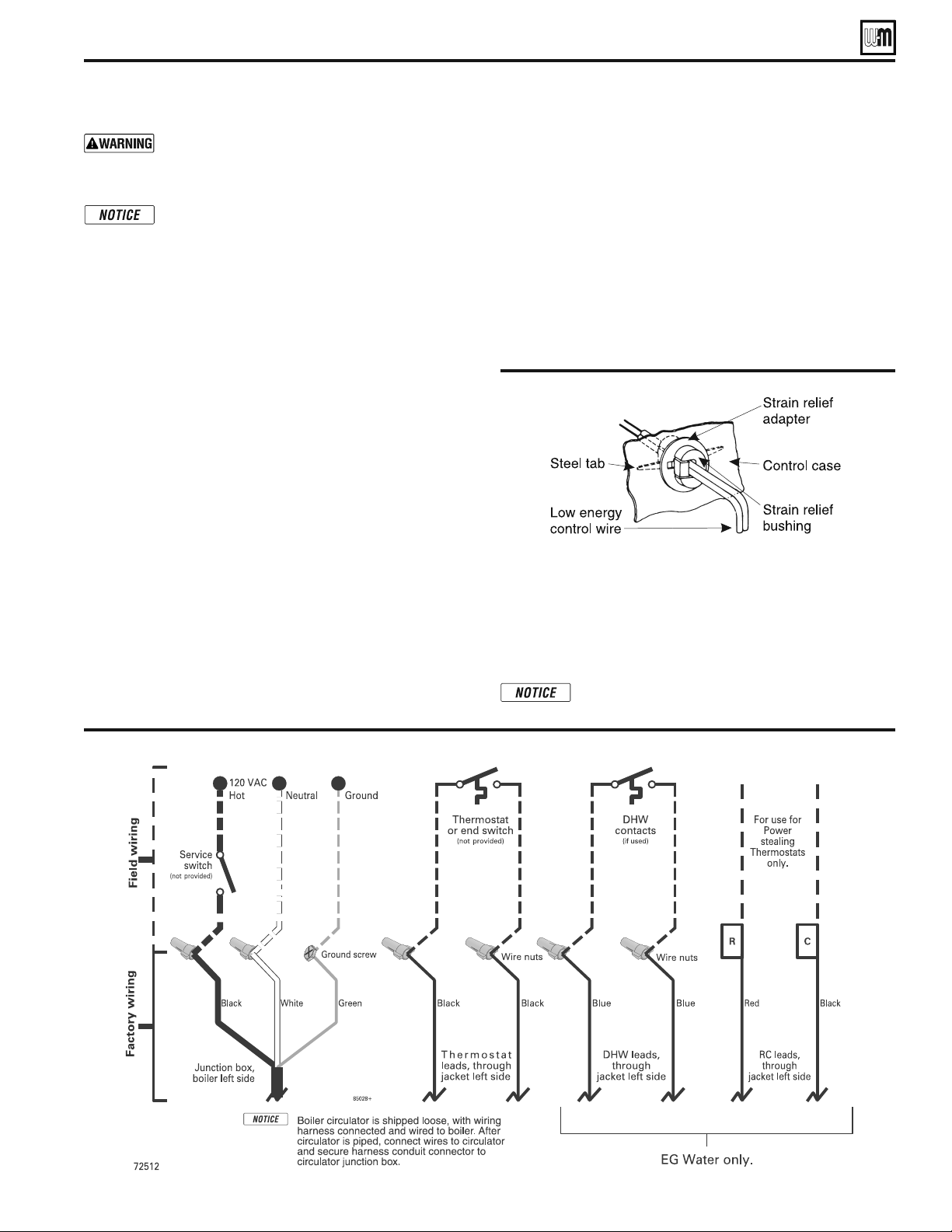

3. See Figure 26 for field wiring. A separate 120VAC electrical

circuit with a fused disconnect switch (15 amp recommended)

should be used for the boiler.

4. A strain relief bushing and adapter must be used at each point

where wiring passes through control case (see Figure 27) to

protect wiring insulation.

5. Multiple zones — Refer to zone valve manufacturer’s literature

for wiring and application. A separate transformer is required

to power zone valves. Zoning with circulators requires a relay

for each circuit.

Room thermostat

1. Connect thermostat as shown on wiring diagram on boiler.

2. Install on inside wall away from influences of drafts, hot or

cold water pipes, lighting fixtures, television, sunrays or fire-

places.

3. If thermostat has a heat anticipator, set heat anticipator in

thermostat to match power requirements of equipment con-

nected to it. Refer to the appropriate Control Supplement for

instructions on the thermostat anticipator setting.

&IGURE Provide strain relief

ConneFt Àeld ZLrLnJ to EoLler

&IGURE Connect field wiring in boiler junction box as shown below. See Control Supplement for more details.

DHW (if used)

Connect the DHW aquastat as shown in wiring below. The

Economy function of the control is not utilized with DHW

input.

R & C Connections (if used)

6!#LEADSSHOULDBEUSEDFORPOWERSTEALINGTHERMOSTATSONLY

Other devices requiring 24 VAC should have sepa-

rate power supply.

EG

&

PEG SERIES 5

s

EGH SERIES 5 GAS-FIRED BOILERS — BOILER MANUAL

Loading ...

Loading ...

Loading ...