Loading ...

Loading ...

Loading ...

4ABLE Boiler feed system sizing

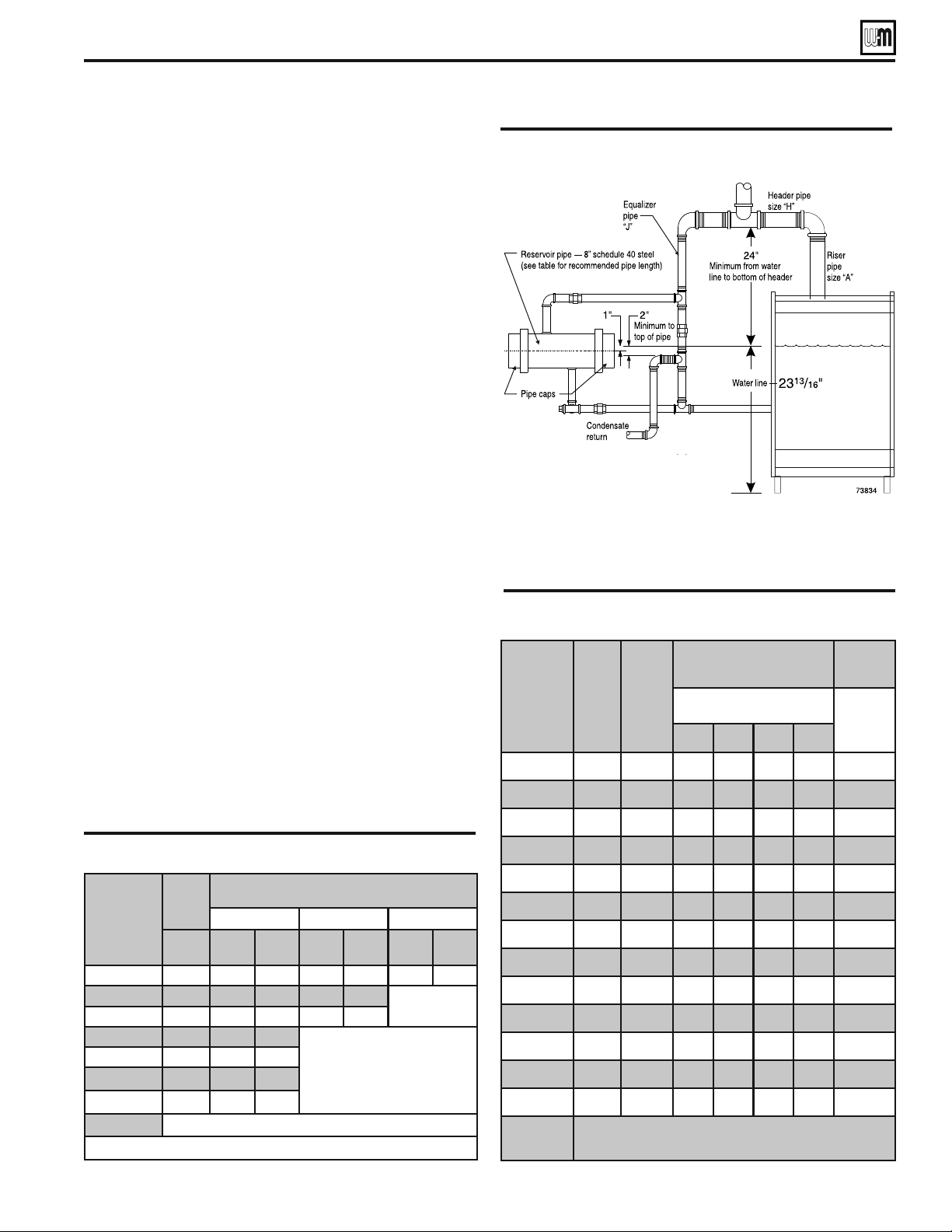

&IGURE Recommended piping for parallel-flow systems

with optional reservoir pipe

3DUW1XPEHU

19

Condensate return

Modern steam boilers are designed to steam for less time than

older, larger boilers. When replacing an older steam boiler the

system condensate return time may be longer than the steaming

time. This could cause the following problems:

1. Boilers fitted with an automatic water feed could overfill.

2. Units fitted with only a low water cutoff would shut down

and cycle while waiting for condensate to return.

Following is a simple method for determining whether or not a

reservoir pipe is required to lengthen steaming time for a resi-

dential installation:

1. Disconnect condensate return line at existing boiler.

2. Heat

boiler and allow to steam for 10 minutes. Turn off boiler.

3. Measure length of time from when boiler started to steam to

when condensate begins to return through condensate line.

4. Measure length of time from when condensate begins to

return to when it stops returning. Divide this time by 2.

5. Add time measured in step 3 to time calculated in step 4. This

sum is the average time required for condensate to return to

the boiler.

6. If this total time is 10 minutes or less, no reservoir pipe is

needed.

If total time for condensate to return to boiler (from step 5) is

more than 10 minutes, a reservoir pipe (or boiler feed system) is

RECOMMENDED3EE4ABLEAND&IGUREFORSUGGESTEDRESERVOIR

pipe size. Install as shown in Figure 20.

&ORLARGERSYSTEMSASNOTEDIN4ABLEUSEABOILERFEEDSYSTEM

with a condensate tank and feed pump. You will have to install a

low water cutoff/pump control on the boiler to operate the pump.

Use Table 9 to size boiler feed systems. See Figure 5, page 10, for

tapping locations. (The use of a combination condensate tank and

float-controlled condensate return pump is not recommended.)

For most residential installations a reservoir pipe may be all that

is necessary to ensure proper operation.

Boiler

model

number

Max.

boiler

gross

output

Time from initial steaming to average condensate return

ERLOHUVWHDPLQJFDSDFLW\EDVHGRQ%WXSHUSRXQGRIVWHDP

15 minutes 20 minutes 30 minutes

MBH gallons

pipe

length

(feet)

gallons

pipe

length

(feet)

gallons

pipe

length

(feet)

EG/PEG-30,-35

75 ¾ ¾ 1 ½ 1 ½ 3 2 ½

EG/PEG-40,-45

125 1 ¼ 1 ¼ 2 ½ 2 ¼

8VHERLOHUIHHG

V\VWHP

EG/PEG-50

145 1 ½ 1 ½ 3 2 ½

EG/PEG-55

167 1 ¾ 1 ¾

8VHERLOHUIHHG

V\VWHP

EG/PEG-65

209 2 ¼ 2 ¼

EG-75

247 2 ½ 2 ½

EGH-85

243 2 ½ 2 ½

EGH-95 up Not recommended –– Use boiler feed system if needed

'HVLJQHGIXOOFDSDFLW\VWHDPLQJWLPHRIPRGHUQERLOHUVLVPLQXWHV

4ABLE Reservoir pipe sizing

Boiler

Model

Gross

Output

Pounds

Steam

Per

Hour

Gallons

Conden-

sate

Per

Hour

Minimum Condensate

Receiver Capacity (Gal.)

Recom-

mended

Maximum

Minutes of boiler

operation:

Feed

Pump

Capacity

GPM

*

15 30 45 60

EG/PEG-30

65 7 ½ 2 5 7 10 0.3

EG/PEG-35

86 10 3 7 10 13 0.3

EG/PEG-40

108 12 ½ 4 8 12 17 0.4

EG/PEG-45

130 15 5 10 15 20 0.5

EG/PEG-50

151 17 ½ 6121723 0.6

EG/PEG-55

174 20 7 13 20 27 0.7

EG/PEG-65

218 25 8 17 25 33 0.8

EG-75

257 29 ½ 10 20 29 39 1.0

EGH-85

253 29 10 19 29 39 1.0

EGH-95

290 33 ½ 11 22 33 45 1.1

EGH-105

325 37 ½ 12 25 37 50 1.3

EGH-115

361 41 ½ 14 28 41 55 1.4

EGH-125

398 46 15 31 45 61 1.5

*

,ISXPSFDSDFLW\H[FHHGVFDSDFLW\VKRZQSXPSFDQ

EHWKURWWOHGZLWKJOREHRUEDOOYDOYH

ConneFt pLpLnJ ² steam EoLlers (continued)

EG

&

PEG SERIES 5

s

EGH SERIES 5 GAS-FIRED BOILERS — BOILER MANUAL

Loading ...

Loading ...

Loading ...