Loading ...

Loading ...

Loading ...

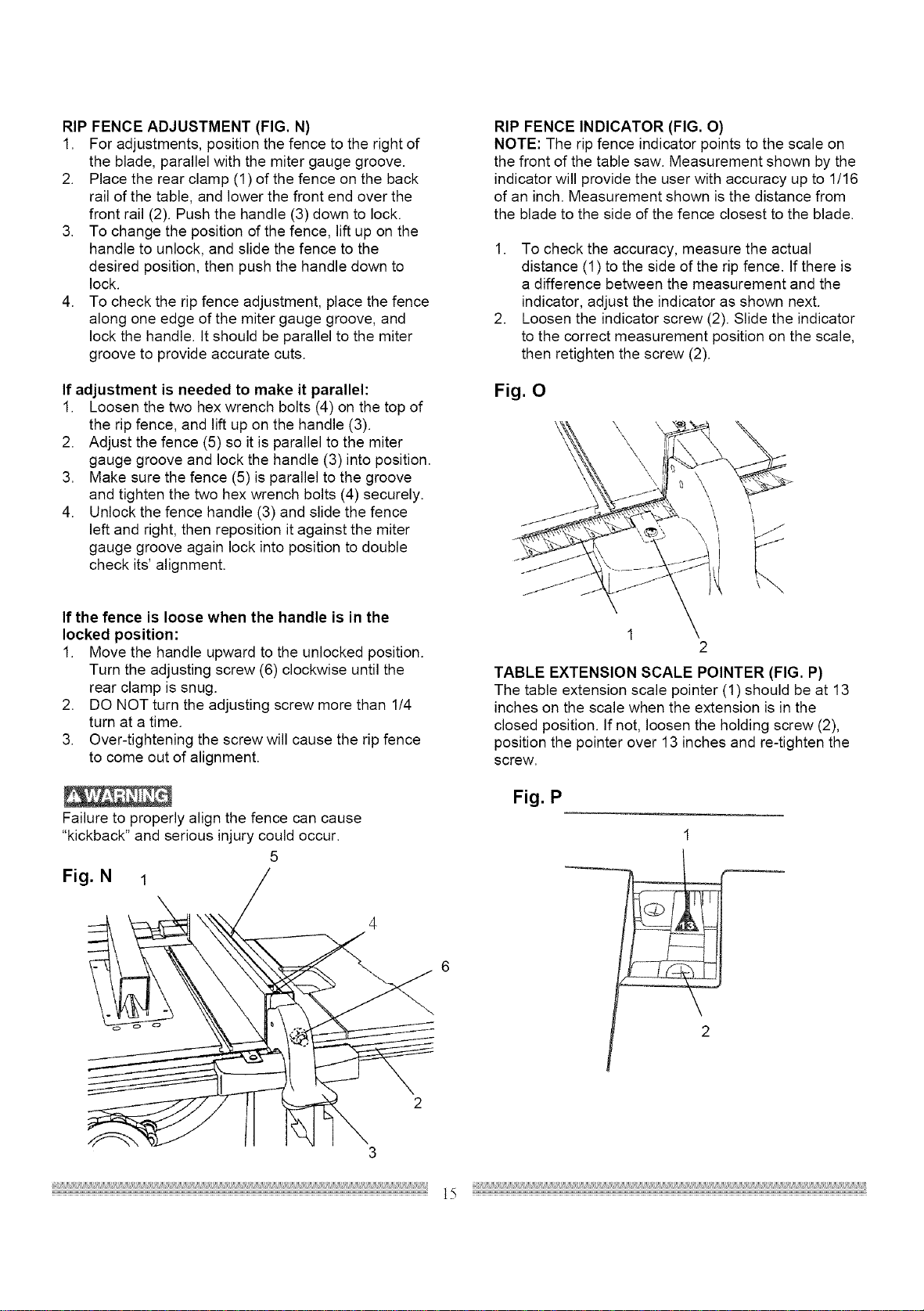

RIP FENCE ADJUSTMENT (FIG. N)

1. For adjustments, position the fence to the right of

the blade, parallel with the miter gauge groove.

2. Place the rear clamp (1) of the fence on the back

rail of the table, and lower the front end over the

front rail (2). Push the handle (3) down to lock.

3. To change the position of the fence, lift up on the

handle to unlock, and slide the fence to the

desired position, then push the handle down to

lock.

4. To check the rip fence adjustment, place the fence

along one edge of the miter gauge groove, and

lock the handle. It should be parallel to the miter

groove to provide accurate cuts.

If adjustment is needed to make it parallel:

1. Loosen the two hex wrench bolts (4) on the top of

the rip fence, and lift up on the handle (3).

2. Adjust the fence (5) so it is parallel to the miter

gauge groove and lock the handle (3) into position.

3. Make sure the fence (5) is parallel to the groove

and tighten the two hex wrench bolts (4) securely.

4. Unlock the fence handle (3) and slide the fence

left and right, then reposition it against the miter

gauge groove again lock into position to double

check its' alignment.

If the fence is loose when the handle is in the

locked position:

1. Move the handle upward to the unlocked position.

Turn the adjusting screw (6) clockwise until the

rear clamp is snug.

2. DO NOT turn the adjusting screw more than 1/4

turn at a time.

3. Over-tightening the screw will cause the rip fence

to come out of alignment.

Failure to properly align the fence can cause

"kickback" and serious injury could occur.

5

Fig. N 1

RIP FENCE INDICATOR (FIG. O)

NOTE: The rip fence indicator points to the scale on

the front of the table saw. Measurement shown by the

indicator will provide the user with accuracy up to 1/16

of an inch. Measurement shown is the distance from

the blade to the side of the fence closest to the blade.

To check the accuracy, measure the actual

distance (1) to the side of the rip fence. If there is

a difference between the measurement and the

indicator, adjust the indicator as shown next.

Loosen the indicator screw (2). Slide the indicator

to the correct measurement aosition on the scale,

then retighten the screw (2).

Fig. O

\ \

\

\

\

1

2

TABLE EXTENSION SCALE POINTER (FIG. P)

The table extension scale pointer (t) should be at 13

inches on the scale when the extension is in the

closed position. If not, loosen the holding screw (2),

position the pointer over 13 inches and re-tighten the

screw.

Fig. P

\

2

2

3

Loading ...

Loading ...

Loading ...