Loading ...

Loading ...

Loading ...

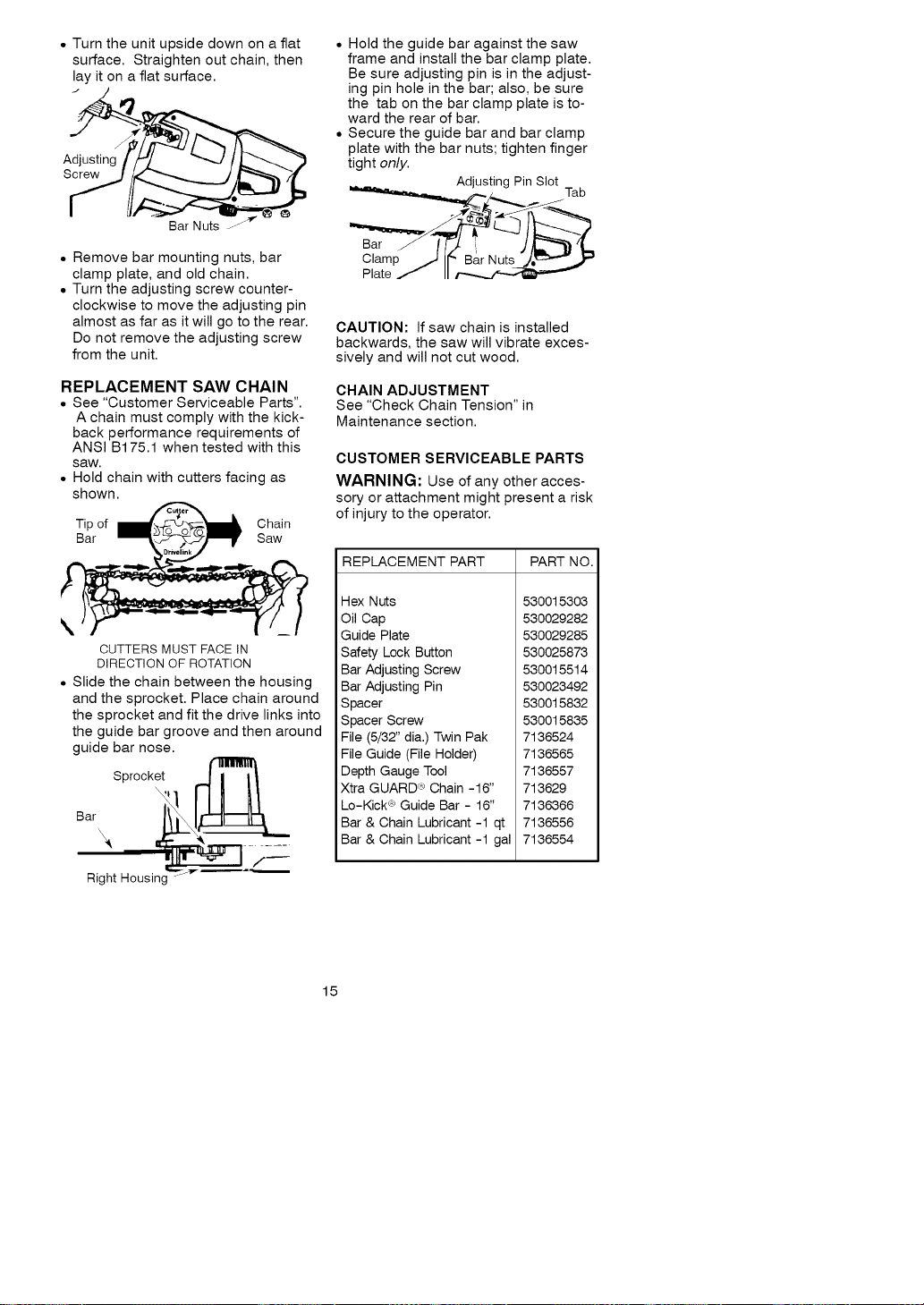

• Turntheunitupsidedownonaflat

surface.Straightenoutchain,then

layitonaflatsurface.

J

Screw

Bar Nuts l-

• Remove bar mounting nuts, bar

clamp plate, and old chain.

• Turn the adjusting screw counter-

clockwise to move the adjusting pin

almost as far as it will go to the rear.

Do not remove the adjusting screw

from the unit.

REPLACEMENT SAW CHAIN

• See "Customer Serviceable Parts".

A chain must comply with the kick-

back performance requirements of

ANSI B175.1 when tested with this

saw,

• Hold chain with cutters facing as

shown.

Tip of Chain

Bar Saw

\

CUTTERS MUST FACE IN

DIRECTION OFROTATION

• Slide the chain between the housing

and the sprocket. Place chain around

the sprocket and fit the drive links into

the guide bar groove and then around

guide bar nose.

Sprocket

Bar \_

Right Housing --

• Hold the guide bar against the saw

frame and install the bar clamp plate.

Be sure adjusting pin is in the adjust-

ing pin hole in the bar; also, be sure

the tab on the bar clamp plate is to-

ward the rear of bar.

• Secure the guide bar and bar clamp

plate with the bar nuts; tighten finger

tight only.

Adjusting Pin Slot

__,_,_jj _ Tab

Bar fF2

Clamp J If" BarNuts_/._'"_ ''

Plate / II

CAUTION: If saw chain is installed

backwards, the saw will vibrate exces-

sively and will not cut wood.

CHAIN ADJUSTMENT

See "Check Chain Tension" in

Maintenance section.

CUSTOMER SERVICEABLE PARTS

WARNING: Use of any other acces-

sory or attachment might present a risk

of injury to the operator.

REPLACEMENT PART PART NO.

Hex Nuts

Oil Cap

Guide Plate

Safety Lock Button

Bar Adjusting Screw

Bar Adjusting Pin

Spacer

Spacer Screw

File (5/32" dia.) Twin Pak

File Guide (File Holder)

Depth Gauge Tool

Xtra GUARD _ Chain -16"

Lo-Kick <_Guide Bar - 16"

Bar & Chain Lubricant -1 qt

Bar & Chain Lubricant -1 gal

530015303

530029282

530029285

530025873

530015514

530023492

530015832

530015835

7136524

7136565

7136557

713629

7136366

7136556

7136554

15

Loading ...

Loading ...

Loading ...