Loading ...

Loading ...

Loading ...

© 2021 United States Stove Company

7

parts that can be easily replaced (i.e. damper parts,

screens, doors and side, and back refractory panels)

are to be removed. These parts must be stored and

readily available for replacement if the appliance is

ever removed. The removal of any parts that render

the replace unusable for burning solid fuel requires

a permanent label to be axed by the installer that

states the replace is unsuitable for burning solid fuel

unless the missing parts are replaced and the replace

is restored to its original, certied condition.

4. Chimney Caps - Mesh type chimney caps and spark

arrestors must be able to be removed for regular

inspection and cleaning. Otherwise the mesh should

be removed to prevent possible plugging. Check your

local re and building codes.

5. Chimney Liner - The chimney must be suitable for

burning solid fuel. Install a continuous stainless steel

liner from the ue collar of the appliance to the top of

the chimney. Liner must be UL Listed to UL1777.

6. Combustible Material Clearances - The replace and

chimney must be inspected to make sure there is

adequate clearance to combustible materials. This

includes the top, side, front, and back as well as

concealed combustibles in the chimney and mantle

areas. Your local building inspector or re authority

should have information on whether older replace

meet current codes and are suitable for use.

7. Makeup Air Requirements - This appliance requires

an adequate supply of makeup air to operate safely

and eciently. In some areas, this is a building code

requirement. Inadequate air supply will cause poor

combustion, inecient operation, creosote buildup,

back drafting and smoke pung into the living areas. If

any of the following conditions are evident, a makeup

air supply MUST be installed.

a. Existing fuel-red equipment shows evidence of

back pung, smoke roll-out, inecient operation, or

excessive smell in the living area.

b. Opening a window or door alleviates any of the above

problems or symptoms.

c. The building is constructed with a well-sealed vapor

barrier, tight tting windows, or has powered exhaust

fans.

d. Excessive condensation on windows in the winter.

e. The building has a ventilation system installed.

f. If, once installed, the solid-fuel appliance does not

draw steadily, burns poorly or ineciently, back-drafts

or experiences back-pung when adding fuel.

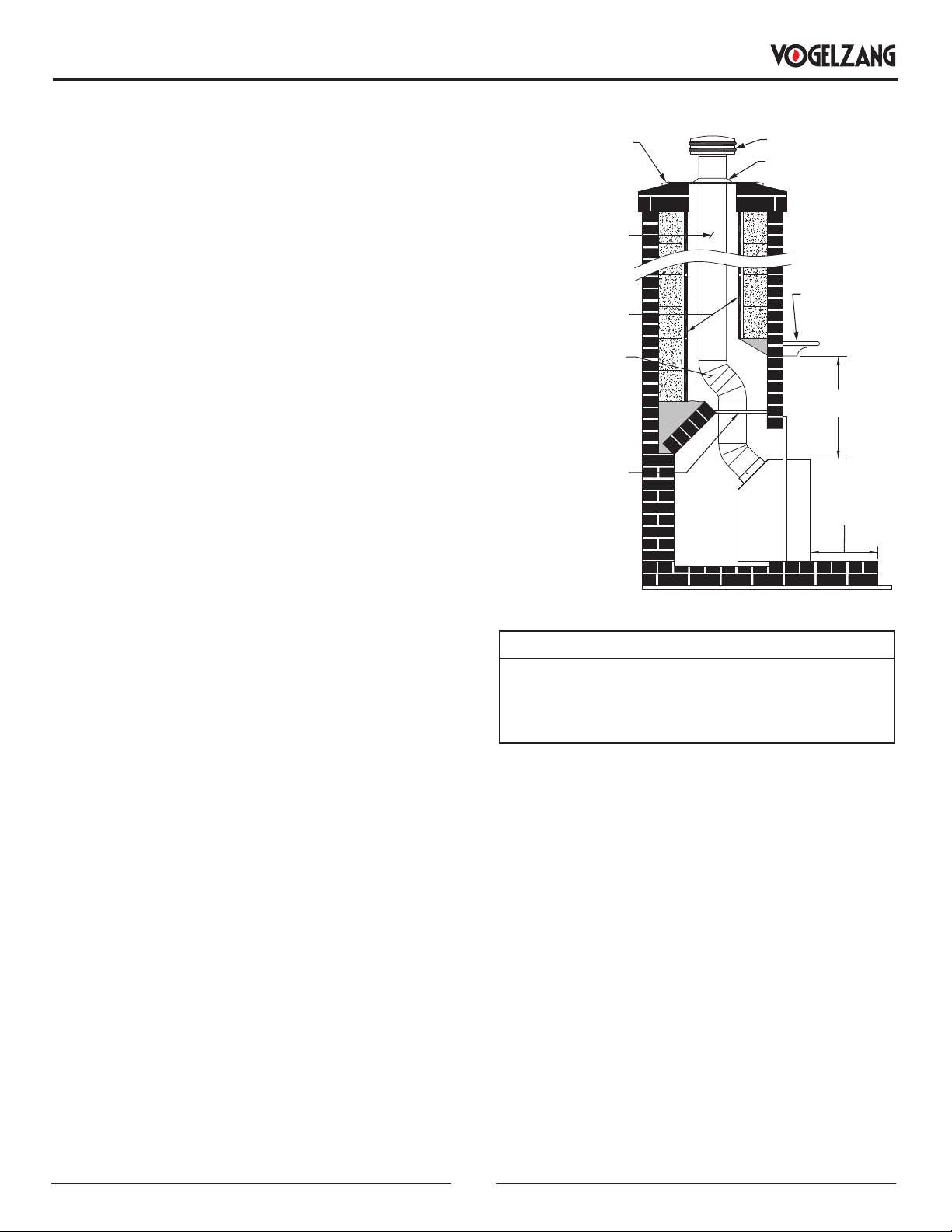

VENTING (DRAFT) REQUIREMENTS

Masonry Fireplace

RAIN CAP

COVER PLATE

(non-combustible)

seal cover plate

with silicone.

UL 1777 STAINLESS

STEEL LINER

Extend to the top of

chimney cap. Follow

the manufacture’s

installation

instructions

MASONRY

CHIMNEY FLUE

6” FLEX FLUE PIPE

SEAL SMOKE

CHAMBER

Smoke chamber

must be sealed with

non-combustible

material to prevent

re-entry of smoke

into the living area.

Accomodations for

inspection and

cleaning must be

maintained.

FLOOR

PROTECTION

Observe min.

clearances

Observe min.

clearances

Mantel

(Combustible)

STORM

COLLAR

WARNING:

RISK OF FIRE - EXCESSIVE DRAFT CAN CAUSE

OVERFIRING AND A POSSIBLE STRUCTURE FIRE.

DO NOT OPERATE THIS APPLIANCE WITH THE FLUE

DRAFT EXCEEDING 0.06 in. w.c. (0.1 Pa).

The chimney ue is a critical component to the proper

and ecient operation of any heating appliance. Heating

appliances do not create draft, draft is provided by the

chimney. This appliance requires a draft of 0.05” water

column (0.1 Pa) at the ue collar. To achieve proper

draft, your chimney must meet three minimum height

requirements; minimum height from top of appliance (15

ft. total height from top of appliance), minimum height

above roof penetration (3 ft.), and minimum height (2 ft.)

above highest point of roof within a 10 ft. diameter from

the chimney. The chimney must also meet minimum and

maximum cross sectional requirements. For that reason a

continuous 6” stainless steel liner from the ue collar to the

top of the chimney is required. A stainless steel adapter is

recommended for fastening the stainless steel liner to the

ue collar. The male (or crimped) end of the adapter must

be installed inside the ue collar to allow condensation or

creosote in the liner to drain back into the rebox. Chimney

liners and/or adapters must be permanently fastened

INSTALLATION

Loading ...

Loading ...

Loading ...