Loading ...

Loading ...

Loading ...

Test the Installation

6

Step 3 - Convert Valves for LP Gas

The bypass jet on each valve must be adjusted. Your

cooktop may come with either hollow or solid valve shafts.

Determine the bypass screw location accordingly.

1. Turn all knobs to the “Off” position.

2. Remove knobs.

Your appliance will have either a) hollow stem valves, or b)

solid stem valves. The location of the adjustment screw is

determined by which type of valve your appliance has.

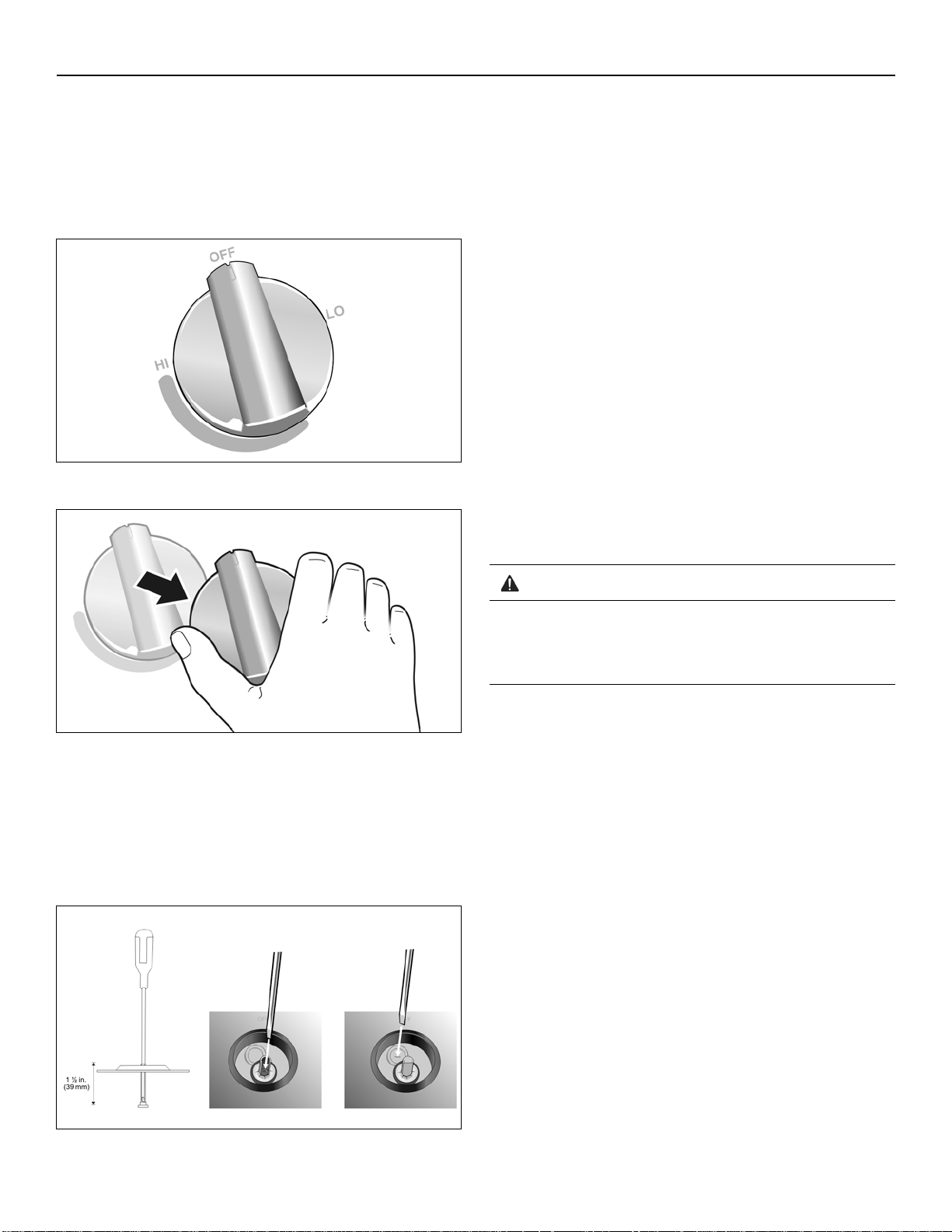

3. Locate the correct point of insertion for the long, thin

flat blade screwdriver to adjust the bypass jet (see the

following illustration).

a) Hollow stem valve - insert a long, thin flat blade

screwdriver in the hollow stem of the valve. The

adjustment screw is approximately 1 1/2” (39 mm)

from the top of the stem. The screwdriver slides

through a thin rubber barrier in the stem (helps

prevent damage in the case of a spill on the unit

surface).

b) Solid stem valve - insert a long, thin flat blade

screwdriver through the seal in the area shown.

3. Engage the tip of the screwdriver into the adjustment

screw by slowly turning the screwdriver and feeling for

the blade to engage the screw. Then turn the screw

clockwise about 70 degrees (less than 1/4 turn) until it

“bottoms out” (does not turn any further). The screw

does not take much pressure to turn. Stop when the

screw does not easily turn any further. Repeat for each

valve until all have been adjusted correctly.

4. Replace the knobs

Test the Installation

Test for Gas Leaks

Leak testing is to be conducted by the installer according to

the instructions given in this section.

Turn on gas. Apply a non-corrosive leak detection fluid to

all joints and fittings in the gas connection between the

shutoff valve and the cooktop. Include gas fittings and

joints in the cooktop if connections may have been

disturbed during installation. Bubbles appearing around

fittings and connections indicate a leak. An electronic Gas

Leak Detector can also be used.

If a leak appears, turn off the supply line gas shutoff valve

and tighten the leaking connections. Retest for leaks by

turning on the supply line gas shutoff valve. When the leak

check is complete (no bubbles appear), the test is

complete. Wipe off all detection fluid residue.

Check Manifold Gas Pressure

During any pressure testing of the gas supply piping

system at test pressures greater than 14" of water column

pressure (approximately ½" psig,

3.5 kPA

) it is necessary to

a. Hollow Stem

b. Solid Stem

WARNING

NEVER TEST FOR GAS LEAKS USING A FLAME.

If any leaks are detected, do not proceed past this

step until all leaks have been eliminated.

Loading ...

Loading ...

Loading ...